Liquid-gas separable liquid rocket engine multi-layer active cooling device

A technology of rocket engines and liquid rockets, which is applied in the direction of rocket engine devices, machines/engines, jet propulsion devices, etc., can solve problems such as unbearable, unable to guarantee cooling uniformity, unfavorable coolant action time, etc., to ensure stability and Safety, stable and uniform cooling effect, and the effect of prolonging the effective working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

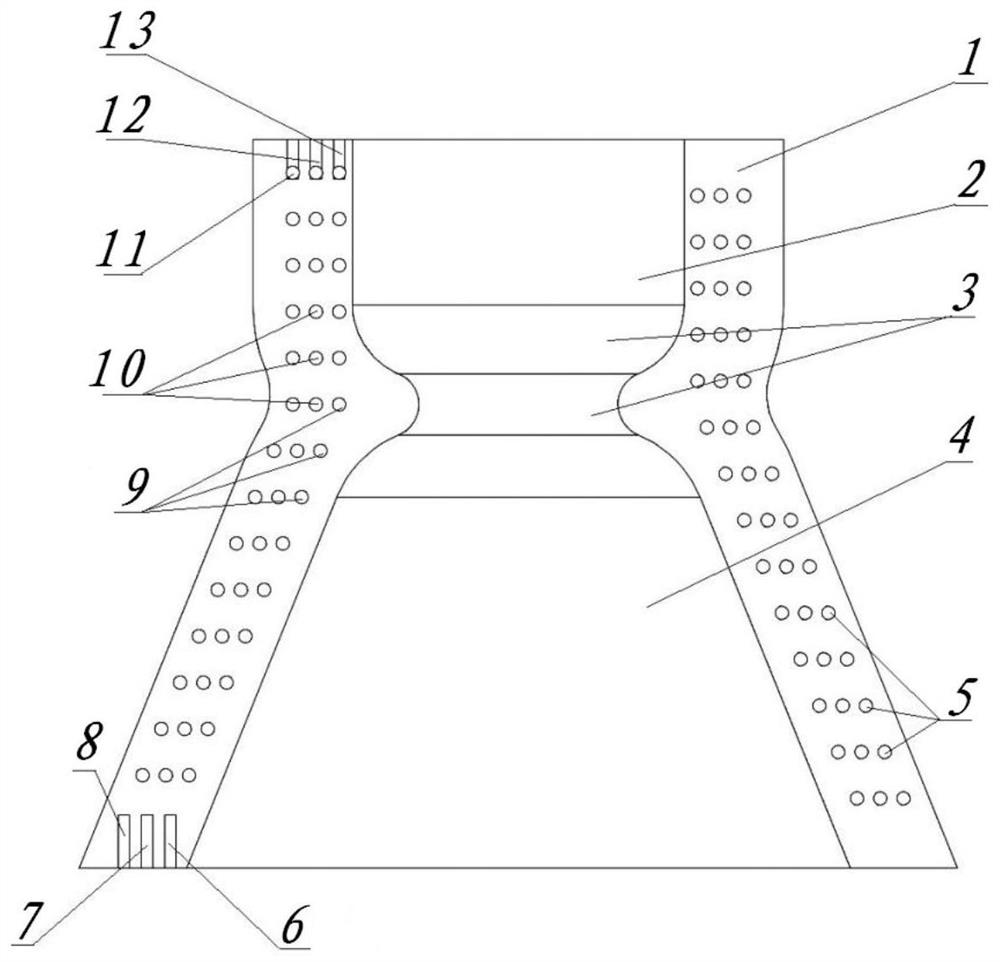

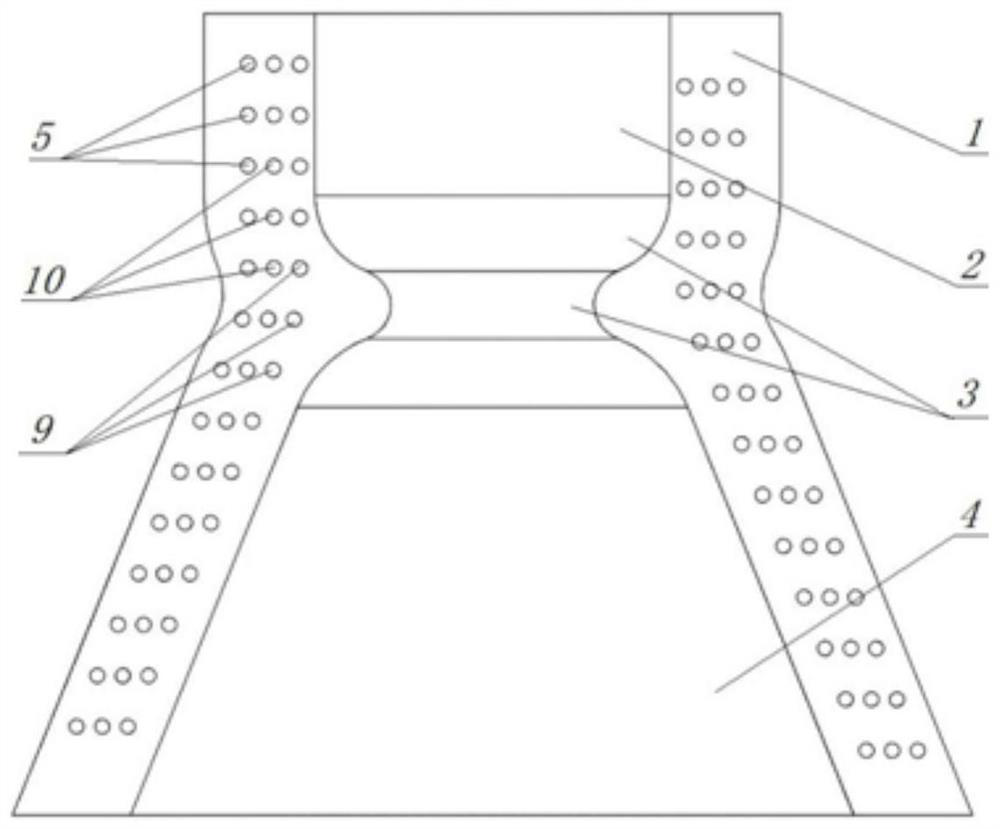

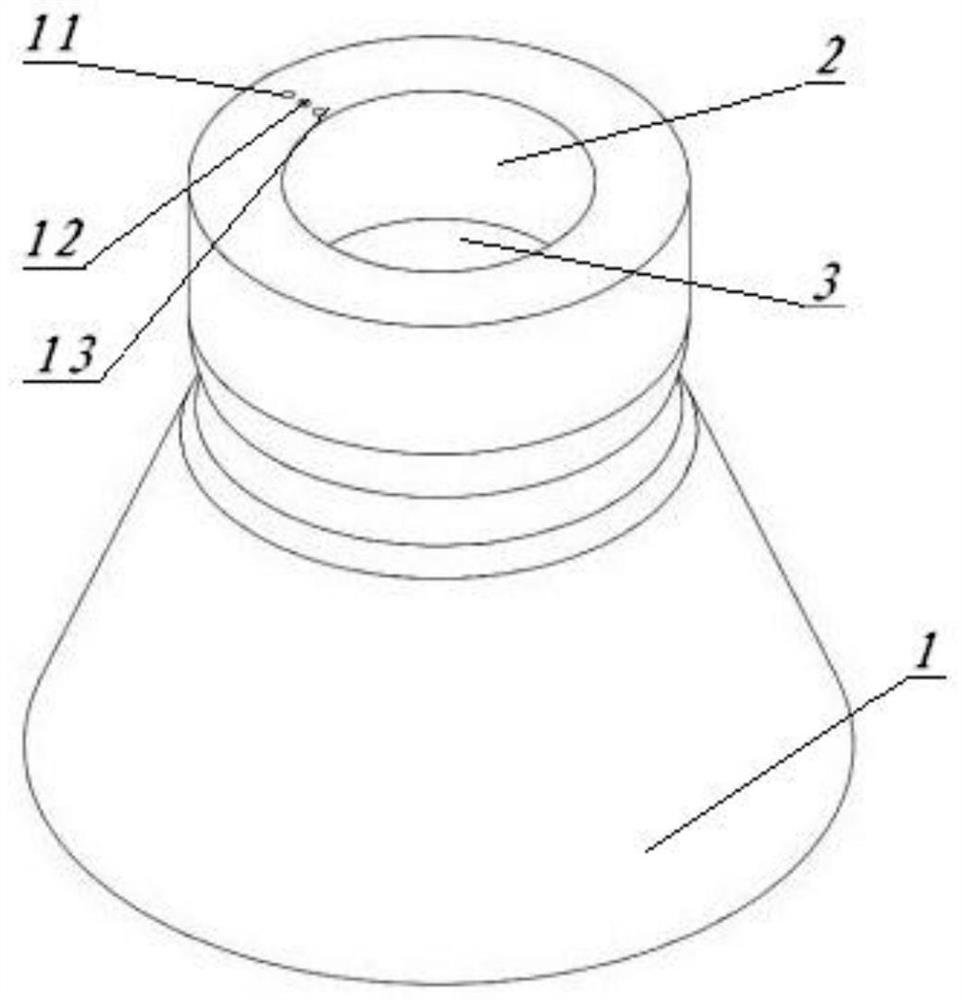

[0041] Such as figure 1 , figure 2 with image 3 As shown, in the present invention, there are three sets of embedded cooling flow pipes for transmitting coolant (coolant is self-carrying fuel in active cooling) (i.e. inner spiral cooling flow pipe 9, middle spiral cooling flow pipe tube 10 and outer layer spiral cooling flow tube 5); each group of embedded spiral cooling flow tubes is an embedded spiral cooling flow tube with a small pitch and the number of spiral nodes is 14-16; the coolant of each embedded spiral cooling flow tube The inlet and the outlet are respectively arranged on the end face of the stave 1 located at the end of the rocket engine nozzle 2 and the end face of the end of the rocket engine combustion chamber 2, and the inlet and the outlet are formed by subtractive machining directly from the outer end face in the vertical direction. , and both are embedded straight pipes intersecting with the respective corresponding embedded spiral cooling flow pipes;...

Embodiment 2

[0051] The working process of using the device of the present invention for active cooling of liquid rockets is as follows:

[0052] In view of the rocket's short working time, one-time work, and extreme harsh working environment, the cooling device has started to work before the rocket is launched. After the safety inspection, the filter 15 with the fuel pump and the shut-off valve opens the shut-off valve, the shut-off valve 16 behind the diverter is opened, the sensing execution and electronic control unit 21 starts to work, and the fuel rail pressure sensor 17, Divider fuel temperature and pressure sensor 18, inner spiral cooling flow pipe pressure sensor 22, middle spiral cooling flow pipe pressure sensor 24, outer spiral cooling flow pipe pressure sensor 23, liquid-gas separator outflow fuel pressure sensor 25 and combustion chamber Corresponding sensors, etc., filter 15 with fuel pump and shut-off valve, splitter fuel pump 20, liquid-gas separator outflow fuel pump 26, ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com