Recycling and laying device and method for water body profile observation system

A technology for profile observation and water bodies, applied in transportation and packaging, cargo handling equipment, buoys, etc., can solve problems such as increased operating costs and risks, high labor cost requirements, and data transmission failures, achieving labor-saving, convenience, and safety. High reliability and reliability, saving labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

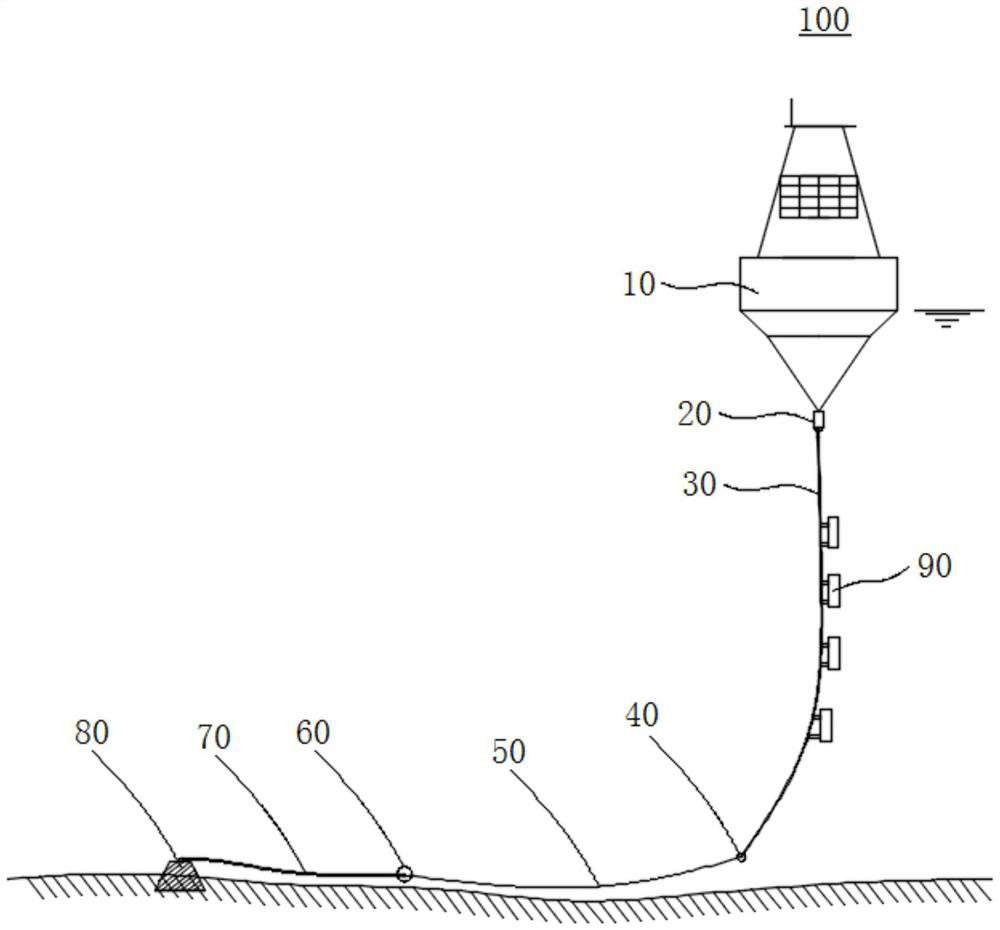

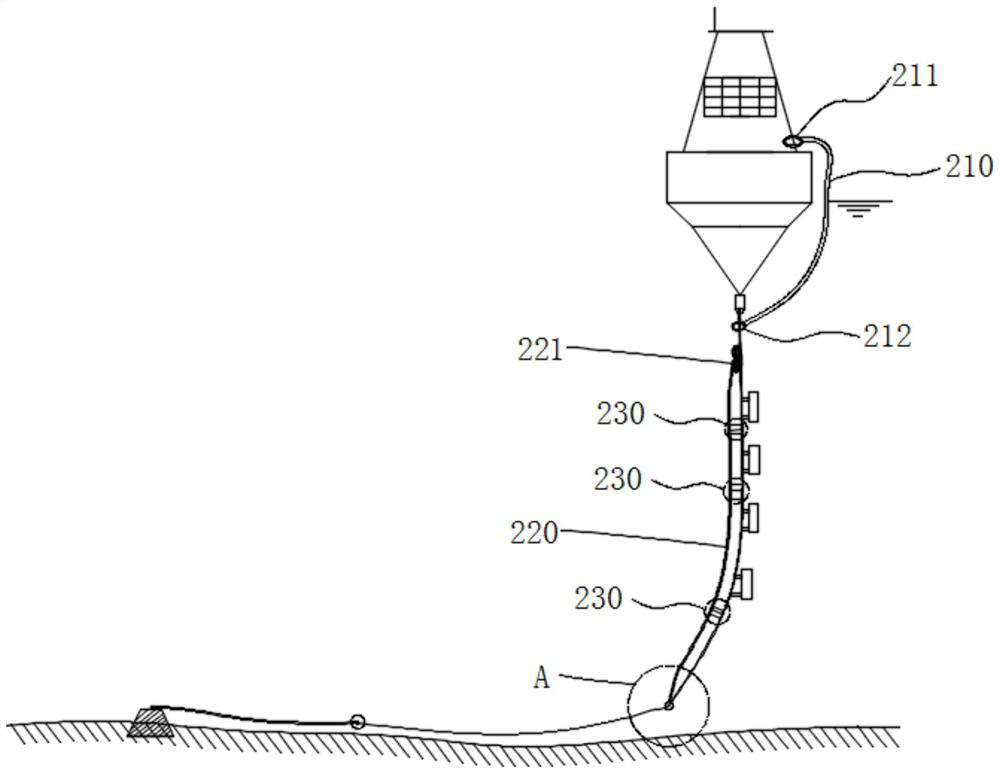

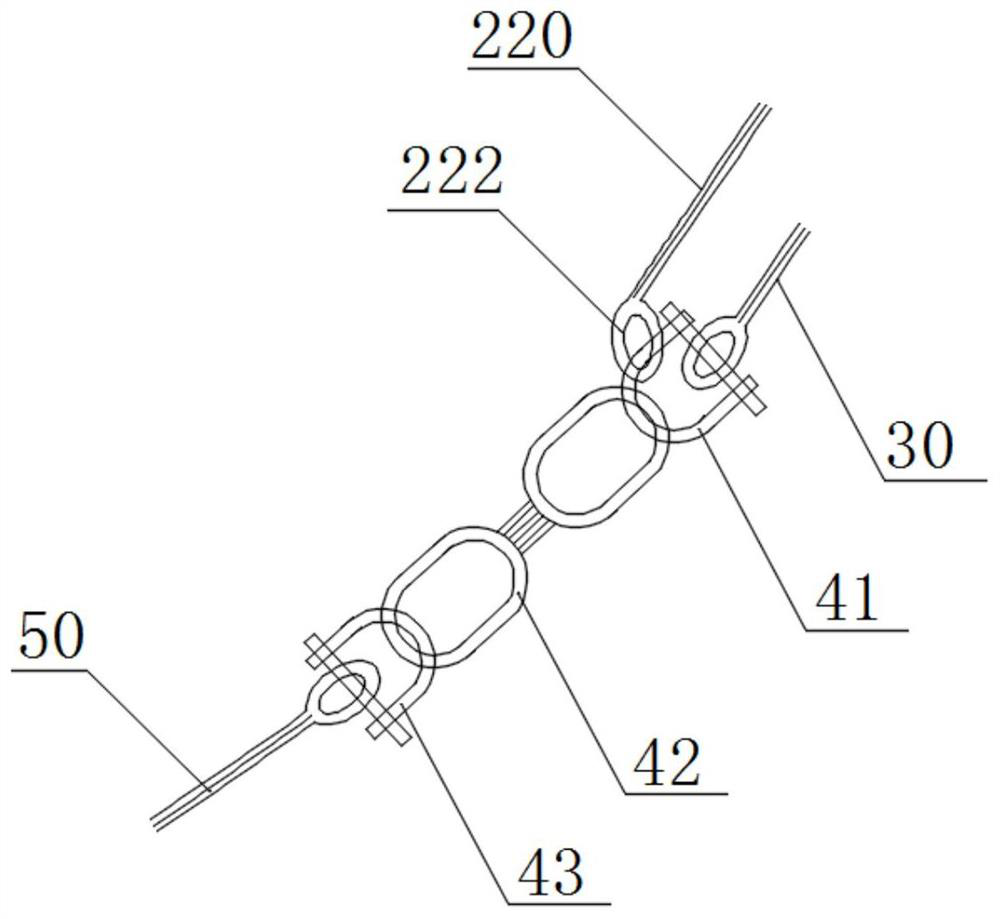

[0041] Such as figure 1 As shown, this is a water body profile observation system 100 commonly used in the field of ocean observation at present, including a buoy body 10 connected in sequence from top to bottom, an electric swivel and a communicator 20, a plastic-coated steel cable 30, and a first connecting piece 40 , a steel wire rope 50 , a second connector 60 , an anchor chain 70 , a weight 80 , and several water body profile observation devices 90 mounted on the plastic-coated steel cable 30 . Wherein, the buoy body 10 provides buoyancy and communication platform for the whole system. The electric swivel and the communicator 20 have two functions: the first is to play the role of the swivel, when the buoy is rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com