Method for forming earth pressure balance shield mud film of water-rich round gravel stratum

A technology of earth pressure balance shield and round gravel, which can be used in earth-moving drilling, mining equipment, tunnels, etc., and can solve the problems of rarely using mud-water balance shield and limited land resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The application provides a method for forming an earth pressure balance shield mud film in a water-rich boulder formation, in which sodium-based bentonite and water are puffed at a mass ratio of 1:8, and the puffing time is 20 hours to prepare a bentonite slurry ;

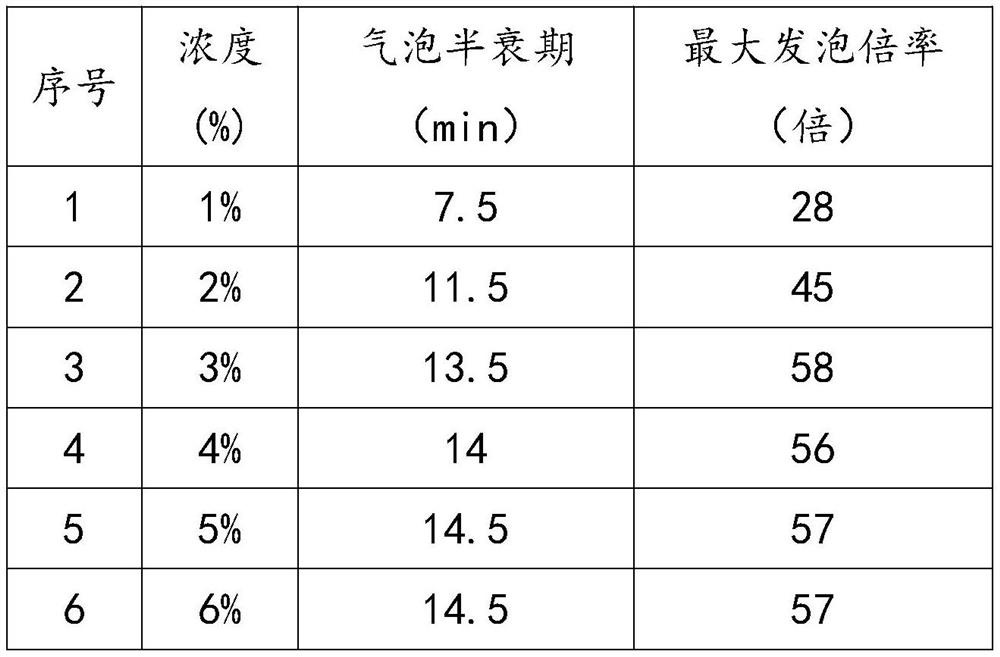

[0030] Add foam agent diluent in bentonite slurry; foam agent diluent mass ratio is 1:2, foam agent concentration 3%, prepares bentonite mud,

[0031] The bentonite mud is covered on the surface of the earth pressure balance shield in the water-rich round gravel formation to form a mud film.

[0032] The foaming agent is Meigu SLF 41, its density at 20°C is 1010-1030kg / m 3 ; The pH value at 20°C is 7.5-8.5. When the foaming agent is mixed with the soil, the following properties can usually be obtained: reducing leakage and strengthening the compactness of the working surface.

[0033] The performance of described sodium bentonite is as follows:

[0034] Montmorillonite: 60%-88%; expansion capacity: 25-50...

Embodiment 2

[0036] The difference with embodiment 1 is:

[0037] The sodium-based bentonite and water are expanded according to the mass ratio of 1:10, and the expansion time is 20 hours to prepare a bentonite slurry;

[0038] Add the bentonite slurry to the diluent of the foam agent; the mass ratio of the diluent of the foam agent is 1:2, and the concentration of the foam agent is 5%, to prepare the bentonite mud.

Embodiment 3

[0040] The difference with embodiment 1 is:

[0041] The sodium-based bentonite and water are expanded according to the mass ratio of 1:12, and the expansion time is 20 hours to prepare a bentonite slurry;

[0042] Add the bentonite slurry to the diluent of the foam agent; the mass ratio of the diluent of the foam agent is 1:4, and the concentration of the foam agent is 5%, to prepare the bentonite mud.

[0043] Different from the mud-water balance shield, the mud film formed on the face of the earth pressure balance shield is not pressurized by a separate mud tank, but the well-proportioned mud acts on the face of the face through the muck improvement system. Because the improved muck has good fluidity, under the action of the pressure of the soil bin, it can continuously act on the excavation surface in front of the cutterhead, maintaining the mud film effect and realizing the stability of the excavation surface and water blocking.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Expansion capacity | aaaaa | aaaaa |

| Mana absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com