Polypropylene composite material and preparation method and application thereof

A technology of composite materials and polypropylene, which is applied in the field of polypropylene composite materials and its preparation, can solve the problems of high density of polypropylene composite materials, unsatisfactory material impact performance, and does not meet the requirements of lightweight, and achieve high impact and low density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

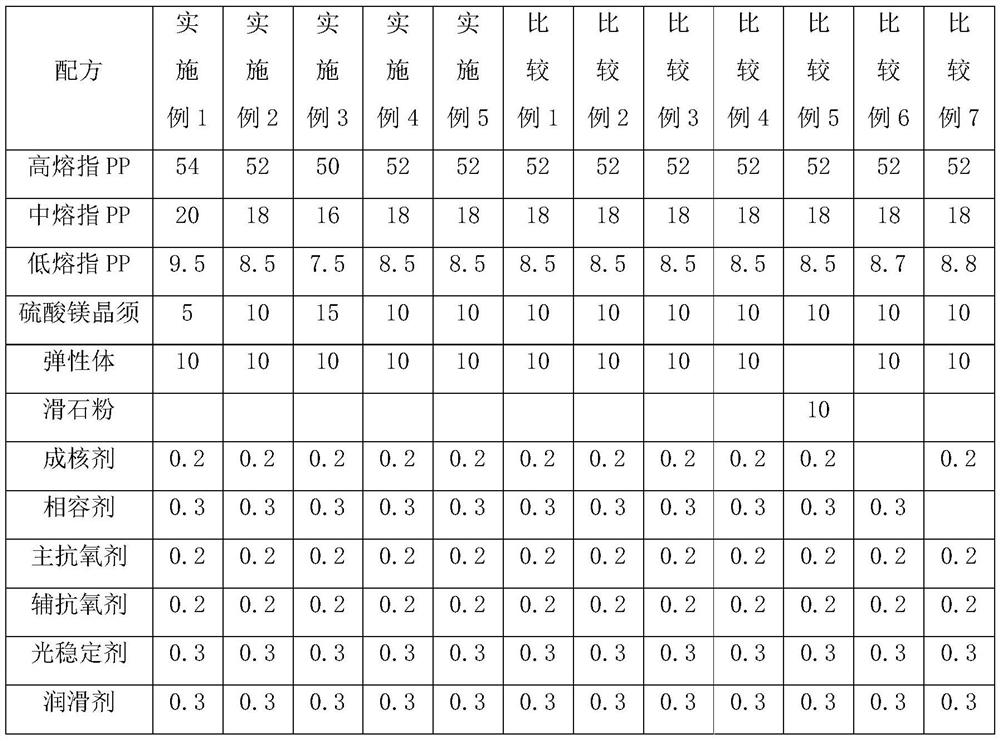

[0045]In this example, 54 parts of PP resin BX3920, 20 parts PP resin K9017H, 9.5 parts of PP resin SP179, 5 parts of the base, magnesium sulfate crystal, WS-1S2, 10 parts, elastic body 8842, 10 parts, nuclear agents Na-11 , 0.3 parts compatible agent CA100, 0.2 parts of antioxidants 1010, 0.2 parts of antioxidants 168, 0.3 parts light stabilizer UV-P, 0.3 parts lubricant AV300, specifically shown in Table 1.

[0046]The shear blocks of the main feed and the side feed are arranged in 45 ° / 45 ° / 90 ° / 45 ° / 90 ° / 90 ° / 45 ° (reverse), the rest is the conveying block; the side feed and the head The shear block is arranged: 45 ° / 45 ° / 45 ° (reverse) / 45 ° / 45 ° / 45 ° (reverse) / 45 ° / 45 ° (reverse), the rest is conveying blocks .

[0047]The preparation step of the polypropylene composite is: adding the above polypropylene resin, an elastomer, a nucleating agent, a compatible agent, and auxiliary agent to a high-speed agitator, stirring at a mixture of 3-5 min, resulting in a ...

Embodiment 2

[0050]In this example, 52 parts PP resin BX3920, 18 parts PP resin K9017H, 8.5 parts of PP resin SP179, and 10 parts of the base, magnesium sulfate crystal, WS-1S2, 10 parts, elastic body 8842, 0.2 parts nucleating agent NA-11 , 0.3 parts compatible agent CA100, 0.2 parts of antioxidants 1010, 0.2 parts of antioxidants 168, 0.3 parts light stabilizer UV-P, 0.3 parts lubricant AV300, specifically shown in Table 1.

[0051]The shear blocks of the main feed and the side feed are arranged in 45 ° / 45 ° / 90 ° / 45 ° / 90 ° / 90 ° / 45 ° (reverse), the rest is the conveying block; the side feed and the head The shear block is arranged: 45 ° / 45 ° / 45 ° (reverse) / 45 ° / 45 ° / 45 ° (reverse) / 45 ° / 45 ° (reverse), the rest is conveying blocks .

[0052]The preparation method of polypropylene composites is the same as in Example 1.

Embodiment 3

[0054]In this embodiment, 50 parts of PP resin BX3920, 16 parts of PP resin K9017H, 7.5 parts of PP resin SP179, 15 parts of the base, magnesium sulfate crystal, WS-1S2, 10 parts, elastomer, 8842, 0.2 parts nucleation agent NA-11 , 0.3 parts compatible agent CA100, 0.2 parts of antioxidants 1010, 0.2 parts of antioxidants 168, 0.3 parts light stabilizer UV-P, 0.3 parts lubricant AV300, specifically shown in Table 1.

[0055]The shear blocks of the main feed and the side feed are arranged in 45 ° / 45 ° / 90 ° / 45 ° / 90 ° / 90 ° / 45 ° (reverse), the rest is the conveying block; the side feed and the head The shear block is arranged: 45 ° / 45 ° / 45 ° (reverse) / 45 ° / 45 ° / 45 ° (reverse) / 45 ° / 45 ° (reverse), the rest is conveying blocks .

[0056]The preparation method of polypropylene composites is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com