Anti-explosion white-reducing device and method for blast furnace granulation tower

A granulating tower and blast furnace technology, which is applied to blast furnace granulating tower explosion-proof and whitening reduction device and its fields, can solve problems such as environmental pollution, affecting the smooth progress of operation, safety and production, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

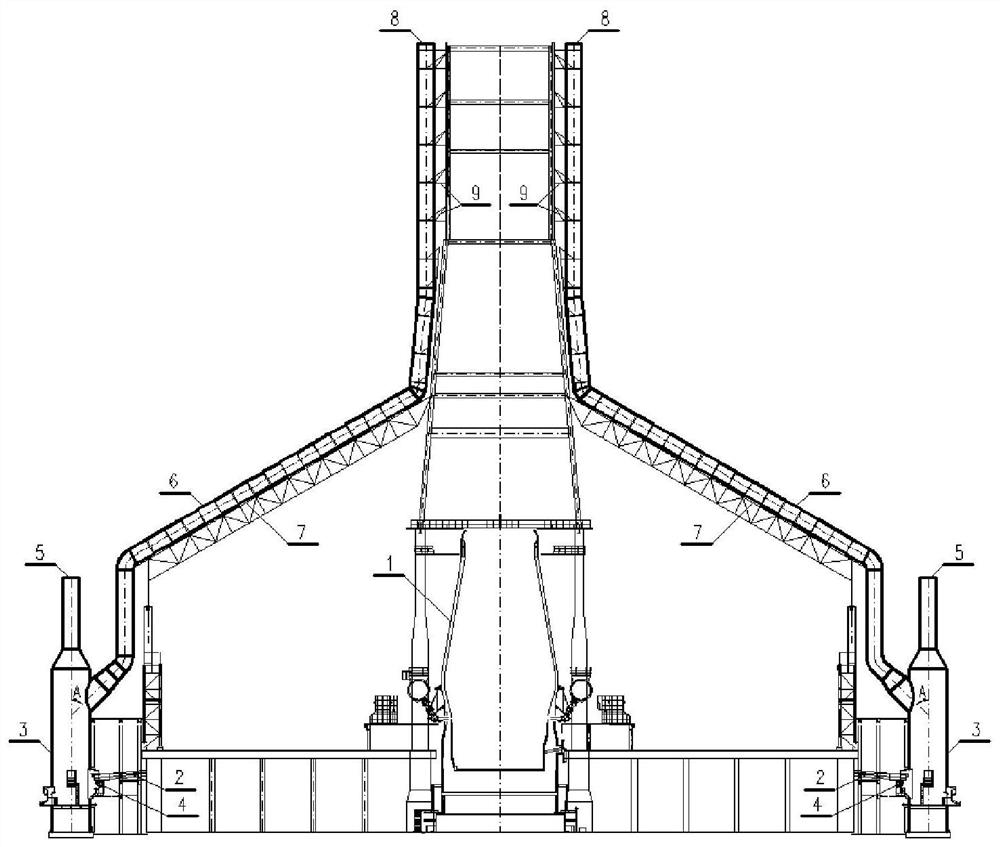

[0021] A blast furnace granulation tower explosion-proof whitening reduction system, characterized in that it mainly includes a blast furnace 1, a slag ditch 2, a granulation tower 3, a granulation nozzle 4, an accidental pressure relief port 5 at the top of the granulation tower, a exhaust gas discharge pipe 6, Casthouse shed 7, exhaust gas discharge pipe outlet 8, exhaust gas discharge pipe fixing frame 9, the blast furnace 1 will produce a large amount of high-temperature slag during the production process, and the high-temperature slag enters the granulation tower 3 through the slag ditch 2 , the granulation nozzle 4 sprays water to the slag, the slag is granulated and cooled in the granulation tower 3, and a large amount of slag-water exhaust steam is generated, and the exhaust steam discharge pipeline 6 is connected with the granulation tower 3 along the The casthouse shed 7 leads to the top of the blast furnace, and is discharged into the atmosphere through the outlet 8 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap