Squirrel-cage squeeze film damper

A technology of squeezing oil film damping and damper, applied in the direction of spring/shock absorber, ball bearing, vibration suppression adjustment, etc., can solve the problems of complex structure, difficult control of stiffness and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

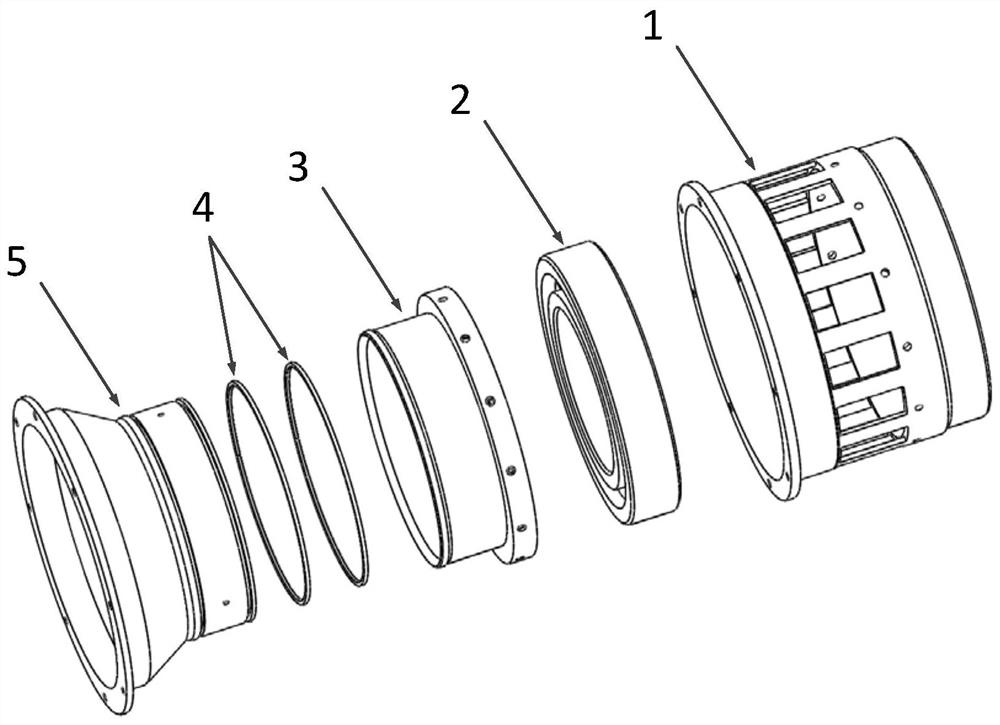

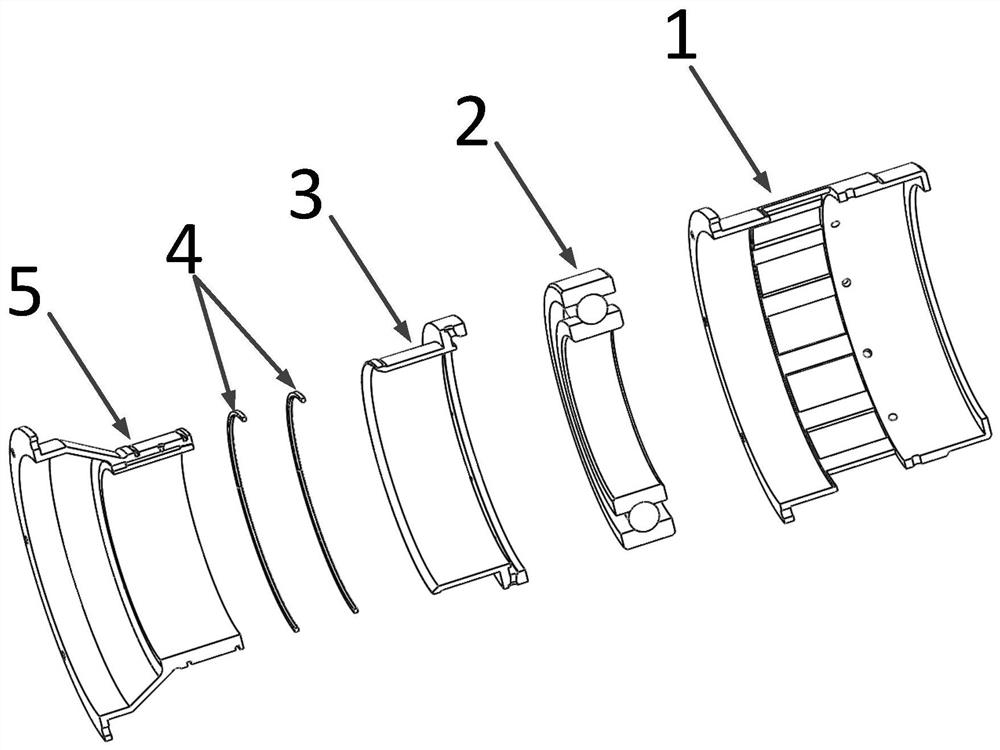

[0039] Specific implementation mode 1: The specific implementation mode of the present invention will be further described below in conjunction with accompanying drawings 1 to 8 .

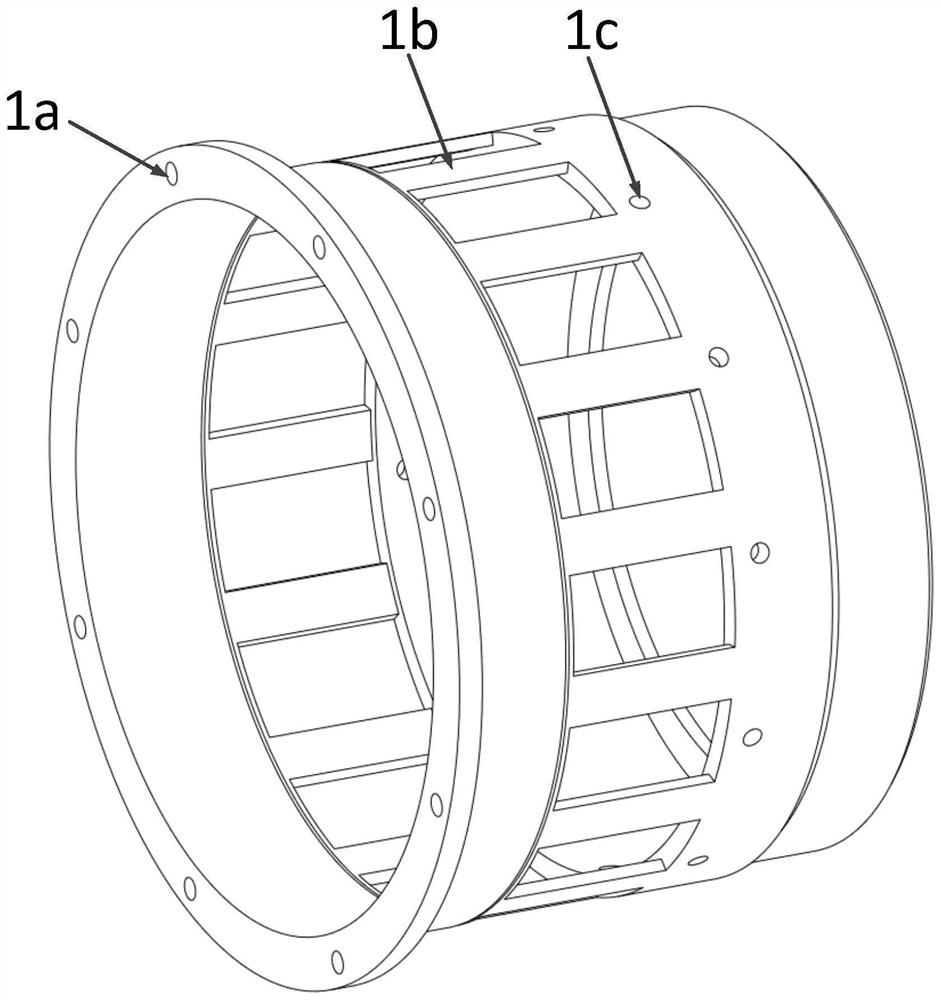

[0040] As shown in Figure 1, a squirrel-cage squeeze oil film damper includes a squirrel-cage housing 1, a bearing 2, a damper outer sleeve 3, a sealing ring 4, and a damper inner sleeve 5; wherein, as shown in Figure 2, The squirrel cage housing 1 generally looks like a hollow cylinder, one end of which is a flange with a threaded hole 1a. The middle part is not completely closed, and is composed of several cage bars 1b. The number, length, width and thickness of the cage bars 1b can be designed according to the needs of the actual support stiffness. Many oil return holes 1c are evenly opened on the squirrel cage housing 1, and the number of oil return holes 1c is designed according to actual needs. The inner diameter of the other end of the squirrel cage housing 1 is slightly smaller to block th...

specific Embodiment approach 2

[0049] Embodiment 2: The ratio of the inner diameters of the large diameter section of the oil inlet 5b, the small diameter section of the oil inlet 5b, and the bearing oil injection hole 5e is 8:4:1; the large diameter section of the oil inlet 5b, the oil inlet 5b The ratio of the lengths of the small-diameter section 5b and the oil injection hole 5e of the bearing is 1:4:1. The oil leakage hole 3a on the outer sleeve of the damper is inclined away from the axial direction of the bearing when viewed from the oil inlet to the oil outlet. In the squirrel cage housing 1, the through holes between adjacent cage bars 1b are rectangular through holes, and the length of the rectangular through holes is 1 / 3rd of the overall length of the squirrel cage housing 1; the width of each rectangular through hole is It is twice the width of the cage bar between adjacent rectangular through holes. The included angle between the axis of the oil injection hole 5e of the bearing and the axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com