Plasma melting furnace device based on flue circular heating

A circulating heating and plasma technology, which is applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of abnormal material discharge, large temperature difference between the upper and lower sides of the magma, and easy solidification, so as to improve fluidity and high-efficiency utilization , the effect of easy nesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

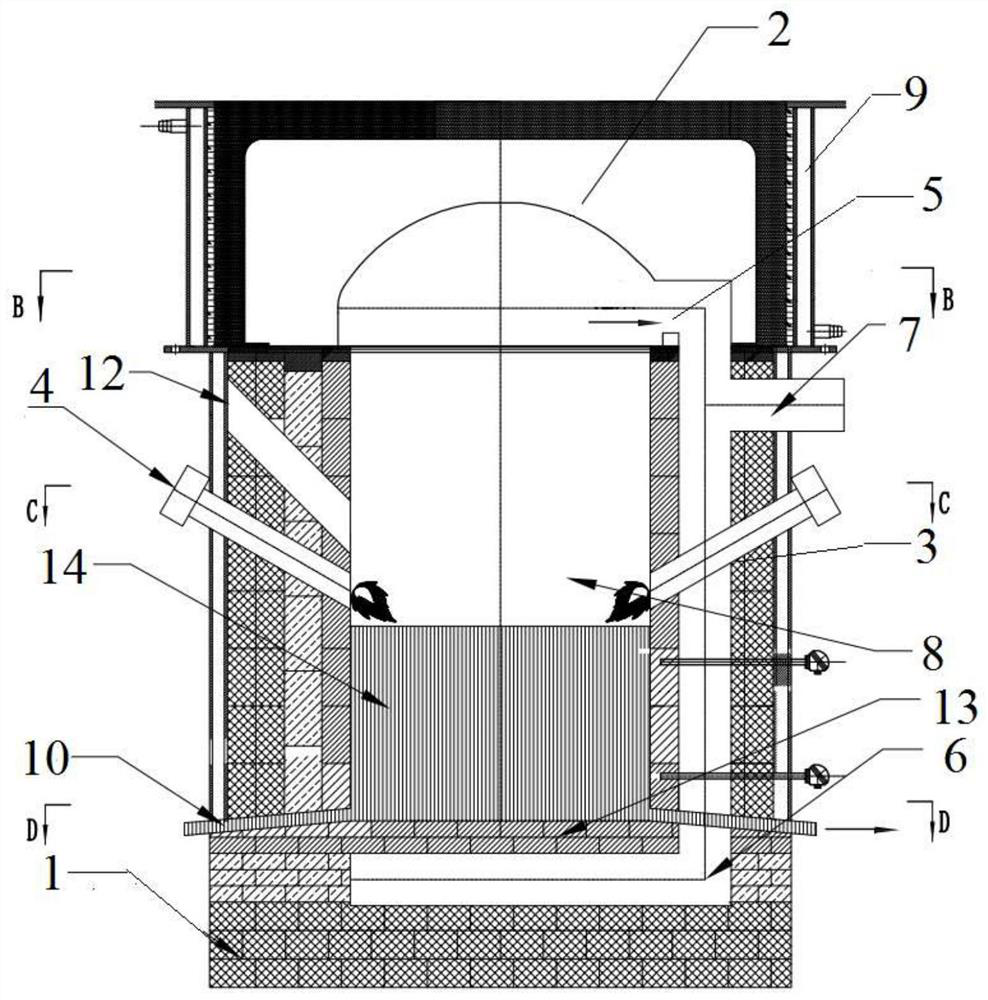

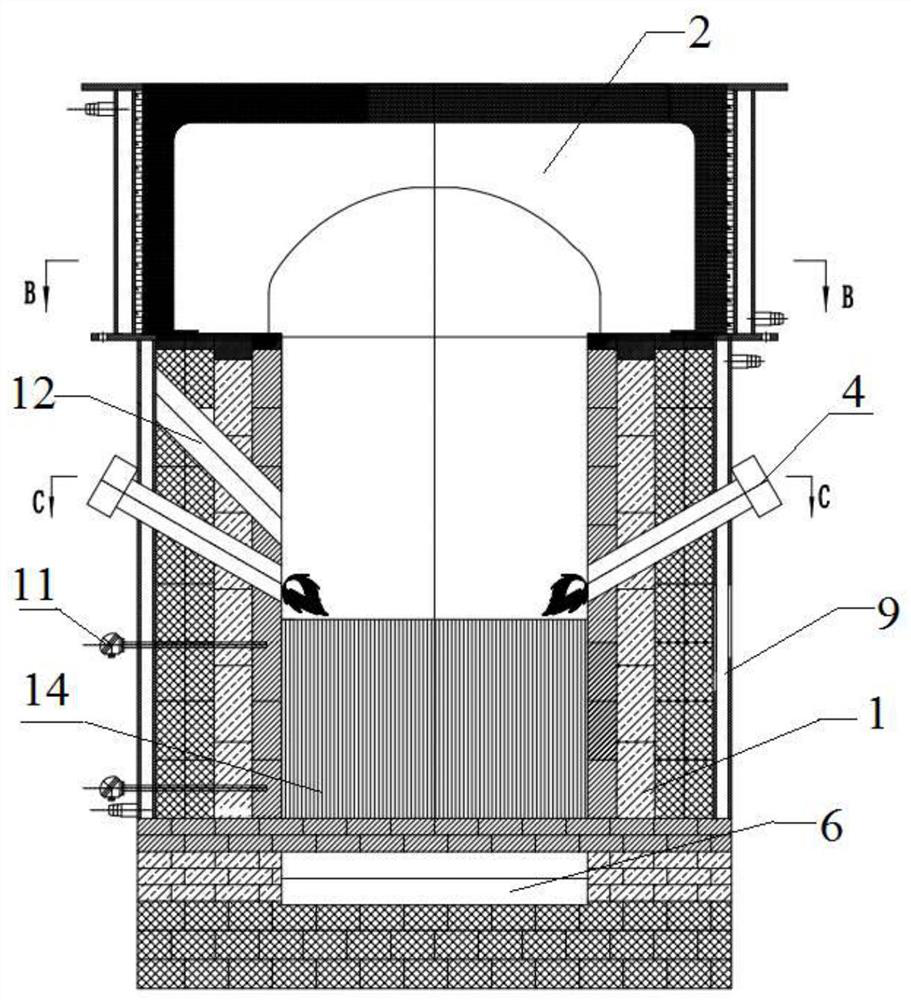

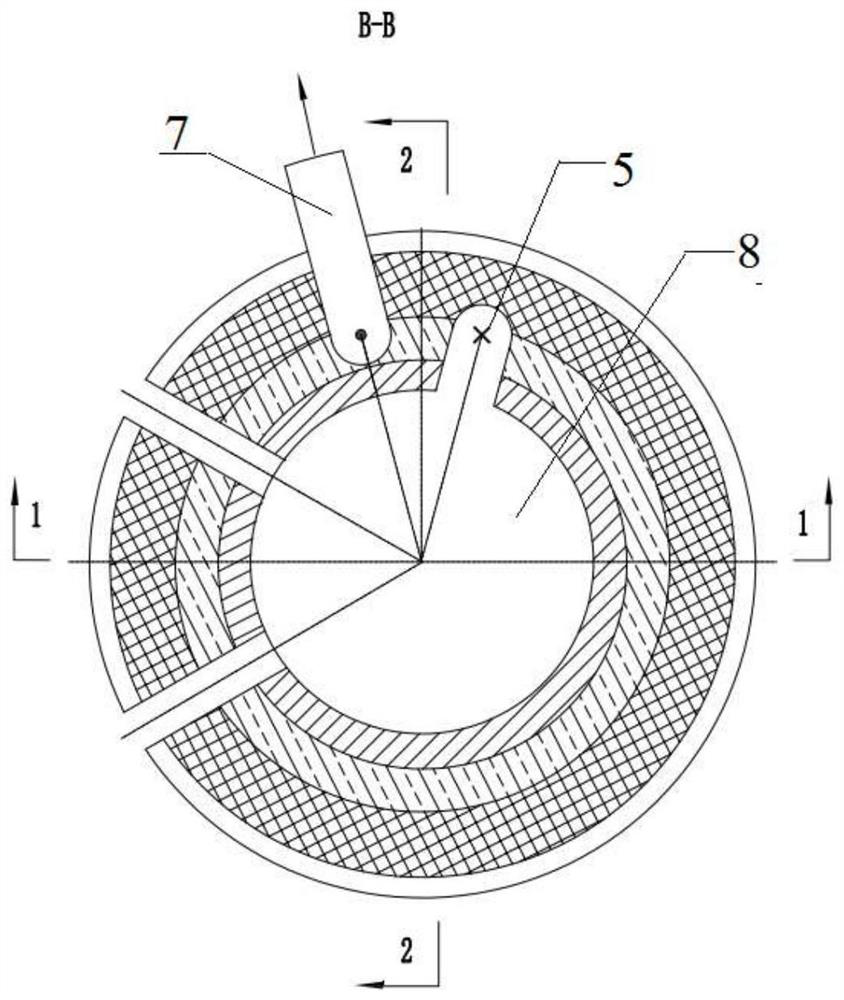

[0024] A kind of plasma melting furnace device based on flue circulation heating of the present invention, such as figure 1 and figure 2 As shown, a furnace body 1 is included, and the furnace body 1 is sealed and connected to the furnace cover 2 to form a furnace hearth 8. A plurality of plasma torch channels 3 inclined downward from the outside to the inside are opened in the side wall of the furnace body 1, and each plasma torch channel 3 The plasma torch 4 is internally connected, the furnace cover 2 is provided with a smoke inlet passage 5, the furnace wall of the furnace body 1 is provided with a circulating high-temperature flue 6 connected to the smoke inlet passage 5, and the outer wall of the furnace body 1 is provided with an exhaust pipe connected with the circulating high-temperature flue 6. The smoke port 7 also includes a dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com