High-sensitivity and wide-range composite conductive nanofiber aerogel sensor and preparation method thereof

A nanofiber, composite conductive technology, applied in the field of sensors, can solve the problems of low sensitivity and saturation, and achieve the effects of high sensitivity, simple overall process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

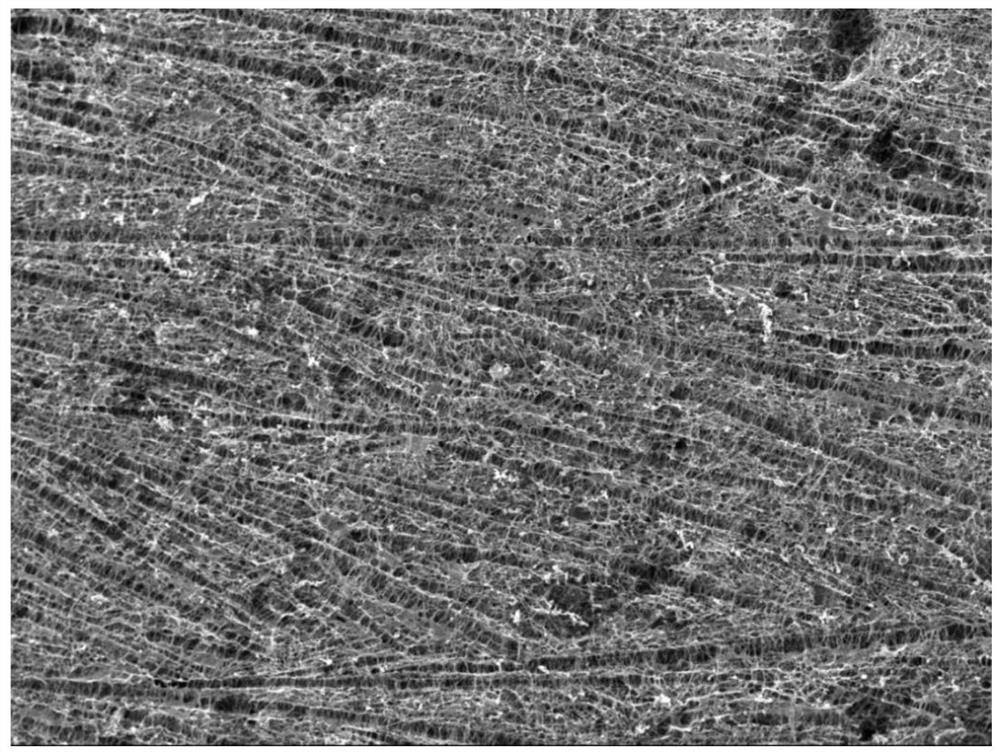

[0047] This embodiment provides a composite conductive nanofiber airgel sensor with high sensitivity and wide range. The content of nanofibers in the nanofibrous aerogels decreased gradually from bottom to top.

[0048] A method for preparing a composite conductive nanofiber airgel sensor with high sensitivity and wide range comprises the following steps:

[0049] S1, dissolving polyvinyl alcohol-ethylene copolymer nanofibers (PVA-CO-PE) in the alcohol-water mixture to form thermoplastic polymer nanofibers with mass percent concentrations of 2%, 5%, 8%, and 10% respectively Suspension, then add PEDOT:PSS conductive material, glutaraldehyde cross-linking agent to make it mass percentage concentration be 6% respectively, mass percentage concentration be 1% HCl to make it mix uniformly and make airgel glue; The mass ratio of the alcohol to water is 5:5;

[0050] S2. The polyvinyl alcohol-ethylene copolymer nanofiber (PVA-CO-PE) mass percentage concentration of 10% airgel glue p...

Embodiment 2

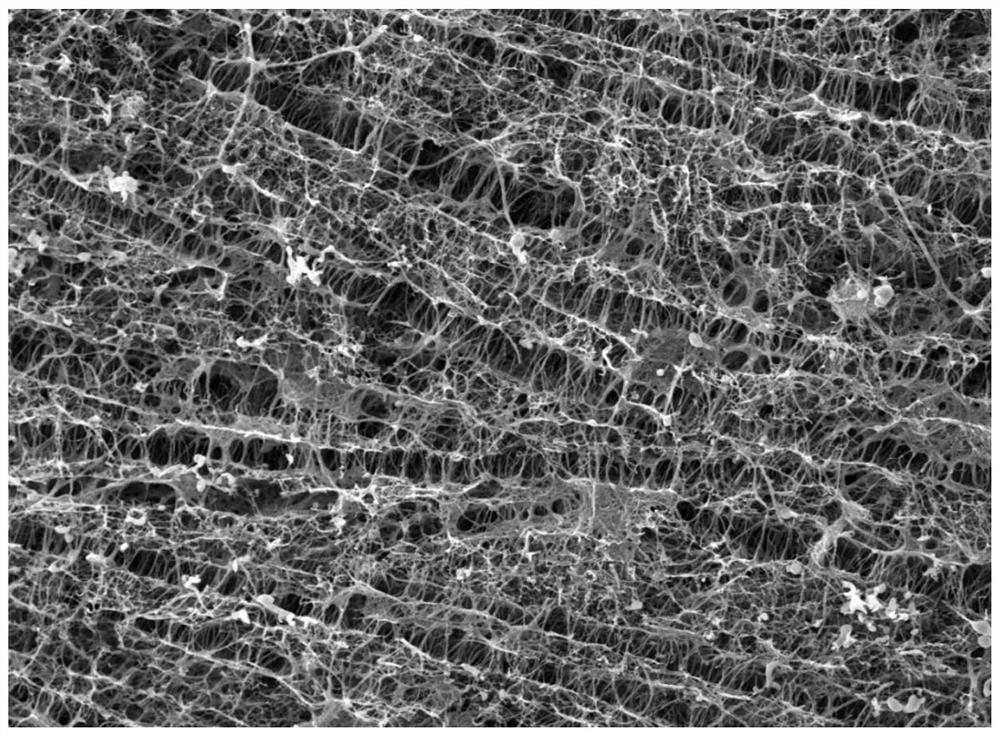

[0060] This embodiment provides a composite conductive nanofiber airgel sensor with high sensitivity and wide range. The content of nanofibers in the nanofibrous aerogels decreased gradually from bottom to top.

[0061] A method for preparing a composite conductive nanofiber airgel sensor with high sensitivity and wide range comprises the following steps:

[0062] S1. Dissolving polyvinyl alcohol-ethylene copolymer nanofibers (PVA-CO-PE) in an alcohol-water mixture to form thermoplastic polymer nanofiber suspensions with mass percent concentrations of 2%, 5%, and 8%, respectively, Then add PEDOT:PSS conductive material, glutaraldehyde crosslinking agent to make it mass percent concentration be respectively 6%, mass percent concentration be 1% HCl to make it mix uniformly and make airgel glue; The mass ratio with water is 5:5;

[0063] S2. The polyvinyl alcohol-ethylene copolymer nanofiber (PVA-CO-PE) mass percentage concentration of 8% airgel glue prepared in step S1 is subj...

Embodiment 3

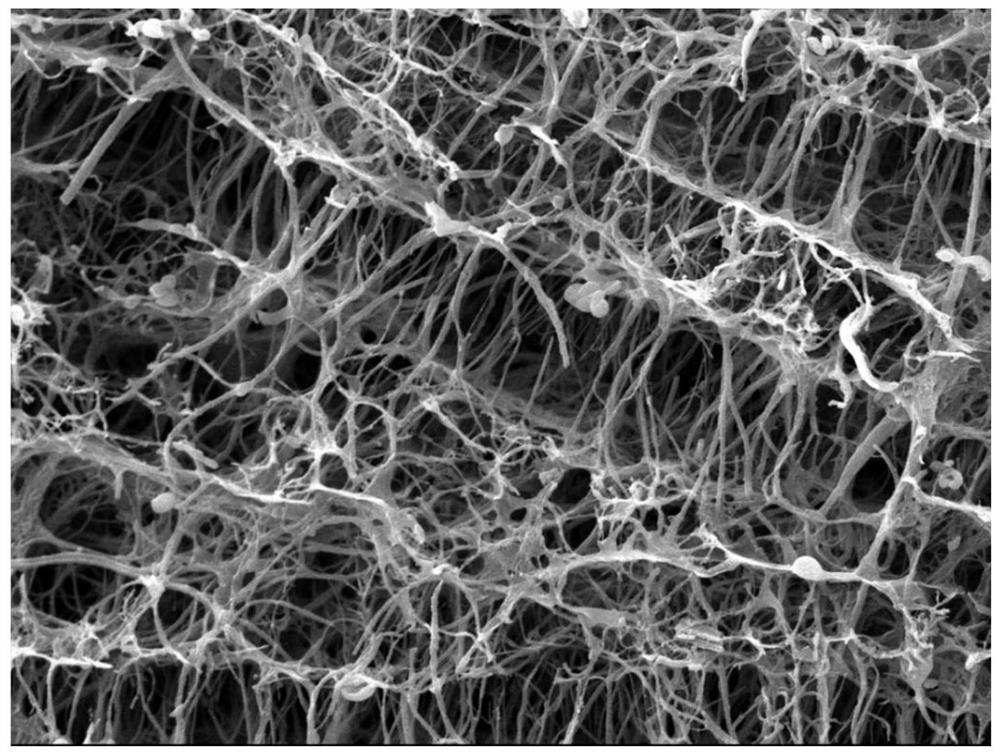

[0070] This embodiment provides a high-sensitivity and wide-range composite conductive nanofiber airgel sensor. The content of nanofibers in the nanofibrous aerogels decreased gradually from bottom to top.

[0071] A method for preparing a composite conductive nanofiber airgel sensor with high sensitivity and wide range comprises the following steps:

[0072] S1. Dissolving polyvinyl alcohol-ethylene copolymer nanofibers (PVA-CO-PE) in the alcohol-water mixture to form thermoplastic polymer nanofiber suspensions with mass percent concentrations of 2% and 5% respectively, and then adding PEDOT:PSS conductive material, glutaraldehyde crosslinking agent make it mass percentage concentration be respectively 6%, mass percentage concentration be 1% HCl make it mix uniformly and make airgel glue; The alcohol and water The mass ratio is 5:5;

[0073] S2. The polyvinyl alcohol-ethylene copolymer nanofiber (PVA-CO-PE) mass percentage concentration of 5% airgel glue prepared in step S1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com