Temperature compensation circuit of silicon pressure sensor

A temperature compensation circuit and sensor technology, which is applied in the measurement of the property force of piezoelectric resistance materials, the measurement of fluid pressure, and the measurement of fluid pressure through electromagnetic components, etc., to achieve easy, high-order harmonic elimination, high compensation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

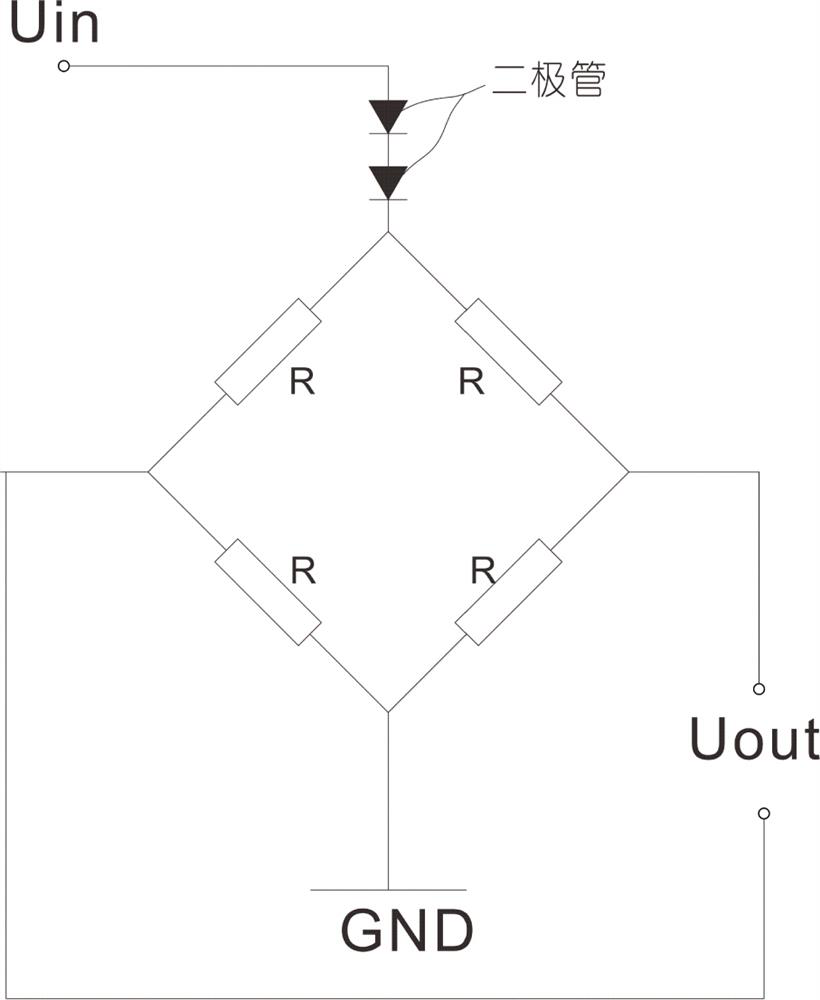

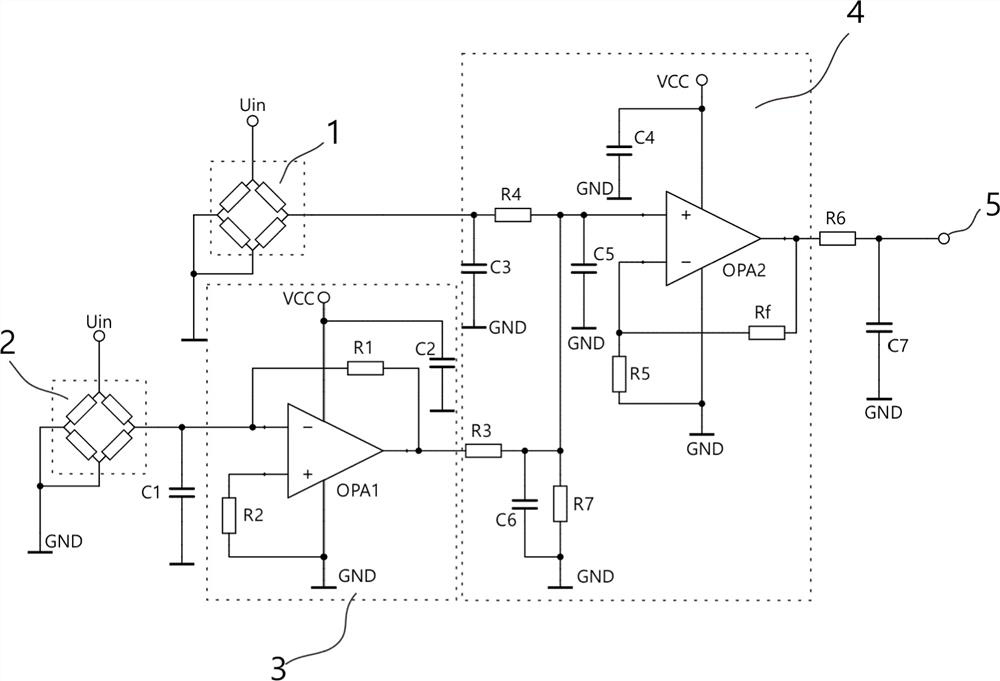

[0020] figure 2 As shown, the embodiment of the present invention provides a temperature compensation circuit for a silicon pressure sensor, in which the semiconductor strain resistance bridge H1 and the semiconductor strain resistance bridge M2 are according to figure 2 The way shown is placed on the elastic base 6 in the same direction, and the elastic base 6 is fixed by the fixed support structure 7 . Bridge 1 consists of four semiconductor strain relief resistors R tH 8 connections, the bridge 2 consists of four semiconductor strain resistors R tM 9 connections constitute.

[0021] The input terminals of bridge 1 and bridge 2 are connected to voltage source and ground, and the voltage source voltage is U in . After the elastic substrate 6 is subjected to external pressure, the semiconductor strain resistance 8 and the semiconductor strain resistance 9 generate strain ε. The strain resistance 8 and the strain resistance 9 are externally led through the lead terminal ...

Embodiment 2

[0025] The pressure sensor has two bridges H and M composed of four semiconductor strain relief connections on the silicon substrate. The input terminal of the bridge H is connected to the voltage source U in , so the bridge output voltage where ΔR tH is the change in resistance value of the bridge H strain resistance under external pressure, R tH is the resistance value of the bridge H strain resistance at temperature T. If the sensitivity coefficient of the bridge H strain resistance at temperature T is K tH , the strain generated under the external pressure is ε, then Therefore, the output voltage U of bridge H at temperature T outH =K tH εU in . Bridge H strain resistance has a negative temperature coefficient β H , sensitivity K tH =K OH (1+β H T), where K OH is the bridge H strain resistance sensitivity at the reference temperature. Therefore, the bridge H output voltage U outH =K OH (1+β H T)εU in =K OH εU in +K OH beta H TεU in , where K OH ...

Embodiment 3

[0031] The pressure sensor designed according to the temperature compensation circuit of the silicon pressure sensor provided by the embodiment of the present invention has lower sensitivity drift error than the silicon pressure sensor using diode bias. For example, using the silicon pressure sensor with the temperature compensation circuit provided by the embodiment of the present invention, the temperature range of the measured medium is -20°C to 125°C, the pressure of the measured medium is 0-16Mpa, and the output signal is 4-20mA. The supply voltage U of the silicon strain gauge bridge in =5V. Sensitivity K of bridge H and bridge M strain resistance at reference temperature (25°C) OH =125,K OM =110, the silicon strain gauge modulus is approximately 400×10 -6 / MPa. The temperature coefficient β of the bridge H H =-2.8×10 -3 , the temperature coefficient β of the bridge M M =-6×10 -3 . Resistance (R 1 ) = 150Ω, resistance (R 2 ) = 170Ω, resistance (R 4 ) = 300Ω, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com