In-service integral composite material R area detection method, reference test block and test block manufacturing method

A technology for comparing test blocks and detection methods, applied in the direction of measuring devices, analyzing materials, processing detection response signals, etc., can solve problems such as undetectable in-situ, and achieve the effect of reducing operation and maintenance costs and large-scale engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

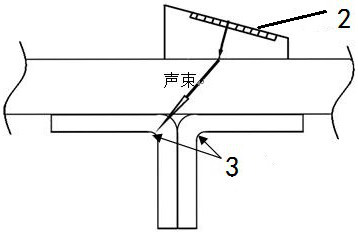

[0069] This example proposes an ultrasonic phased array sector scan imaging detection method for the R-zone of an in-service integrated composite material, which is used for material detection of the R-zone of an in-service integrated composite material product based on the ultrasonic phased array sector scan imaging technology and product quality evaluation, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 , Figure 24 , Figure 25 , Figure 26 , Figure 27 , Figure 28 , Figure 29 , Figure 30 As shown, the R-zone ultrasonic phased array sector scanning imaging detection method of the overall composite material in service includes the following steps:

[0070] Step 1: First, establish the ultrasonic phased array detection simulation model of the R zone of t...

Embodiment 2

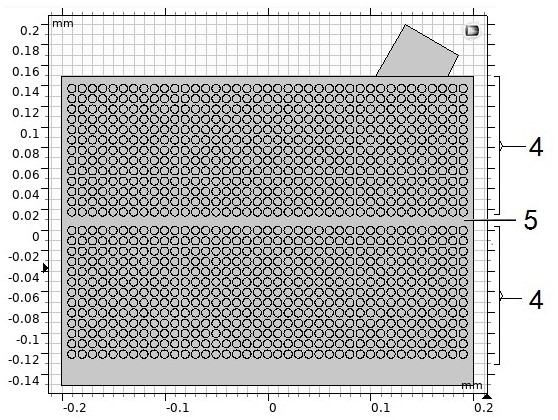

[0089] This example proposes a comparison test block, which is used for the above-mentioned detection method of ultrasonic phased array sector scanning imaging in the R zone of the overall composite material in service, such as Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 As shown, the comparison test block includes a Z rib part, a C rib part and a panel part made of multi-layer composite material prepreg; the panel part is laid flat on the bottom, and the C rib part and the Z rib part are arranged on the panel part to overlap , and the three together constitute the comparative test block of the J-shaped rib structure;

[0090] In the inner layer of the composite material prepreg of the Z rib or / and the R zone of the C rib, artificial defects 8 are placed at dislocation intervals;

[0091] The artificial defect 8 is a double-layer polytetrafluoroethylene circular diaphragm;

[0092] The size of the comparison test block is 190mm×170mm×124mm.

Embodiment 3

[0094] This embodiment proposes a method for manufacturing a comparison test block, which is used to manufacture the above comparison test block, such as Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 The manufacturing method shown includes the following steps:

[0095] Step S1: produce and design the artificial defect 8, and manufacture a double-layer polytetrafluoroethylene diaphragm with a radius of Φ6mm as the artificial defect 8;

[0096] Step S2: Lay up the test blocks. The specific operation is: use 50 sheets of composite material prepreg with a single layer thickness of 0.125mm and a size of 200mm×200mm to form the panel part; use 14 sheets with a single layer thickness of 0.125mm, Composite prepregs with a size of 280mm×200mm are laid up to form the Z-bar; 14 sheets of composite prepregs with a single layer thickness of 0.125mm and a size of 280mm×200mm are laid up to form the C-bar;

[0097] Step S3: Collage the C-bar part, Z-bar part and panel part, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com