Maskless laser direct writing system and maskless laser direct writing method

A laser direct writing, maskless technology, applied in the field of photolithography, can solve the problem of poor maskless patterning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

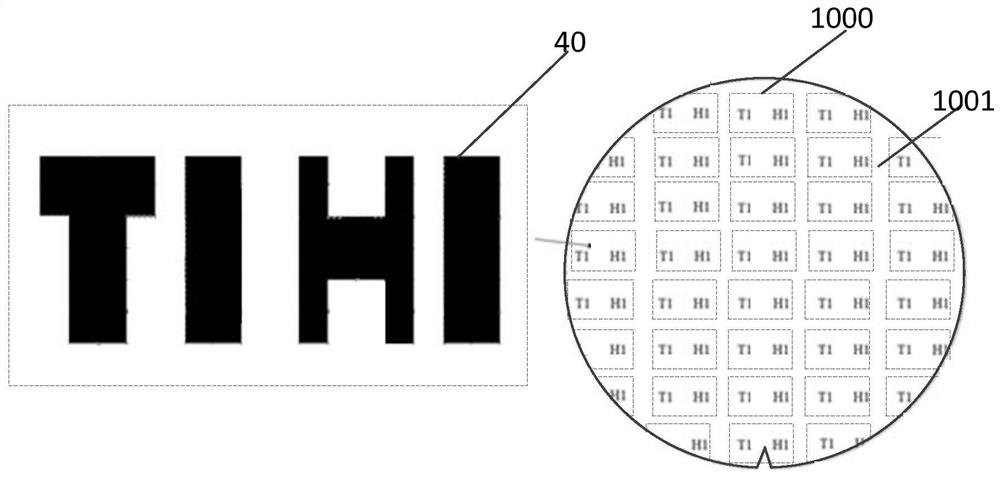

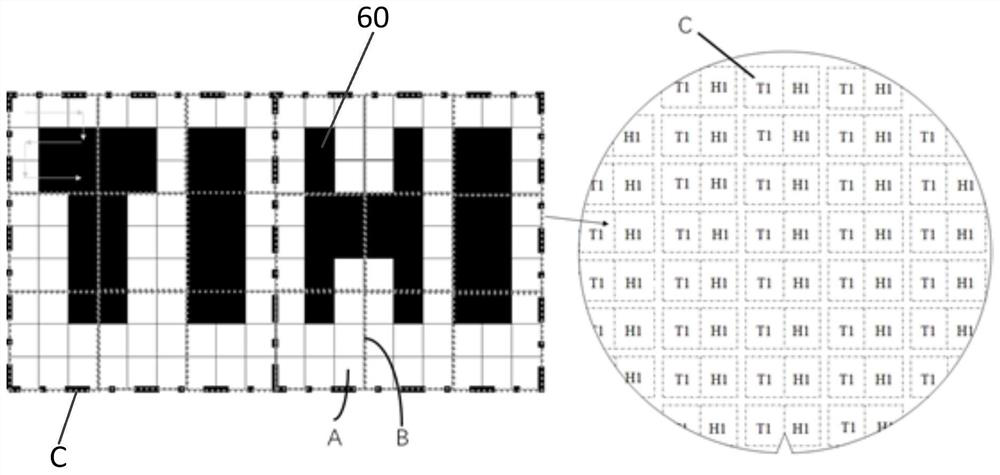

[0032] A maskless laser direct writing system uses multiple optical fibers to generate multiple laser beams for laser direct writing, and improves photolithography efficiency through parallel processing of beams. Since the existing mature optical lithography, especially with the increase of the wafer size, stepping lithography is mostly used, so how to use the laser direct writing system with multiple optical fibers to achieve the effect similar to optical lithography needs to be further studied. solve.

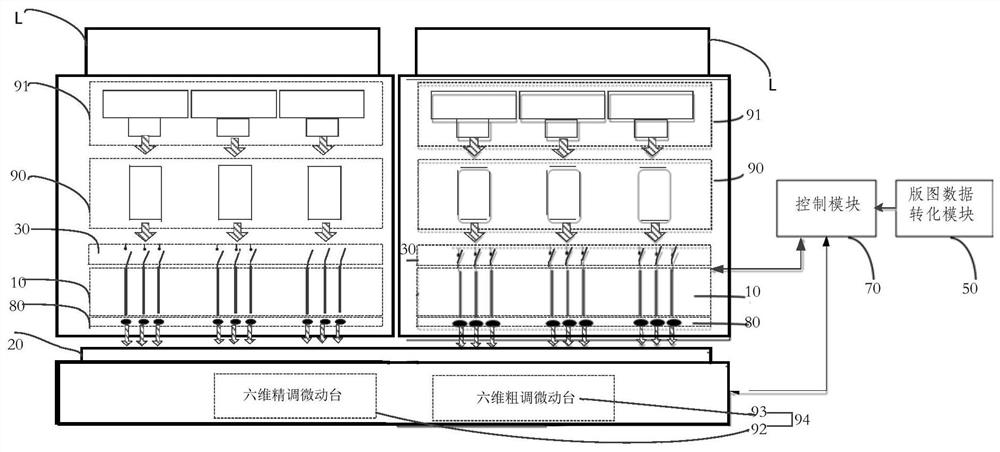

[0033] An embodiment of the present invention provides a maskless laser direct writing system, refer to figure 1 ,include:

[0034] W fiber arrays 10 (reference Figure 4 ), each fiber array 10 includes some M rows*N columns of optical fibers 100 (refer to Figure 5 ), M is an integer greater than or equal to 1, N is an integer greater than or equal to 1, and W is an integer greater than or equal to 2;

[0035] The sample stage 20 is adapted to carry a wafer to be photoet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com