Inorganic heavy metal ion adsorption material and preparation method thereof

A technology for heavy metal ions and adsorption materials, applied in the field of inorganic heavy metal ion adsorption materials and their preparation, can solve the problems of easy desorption, low adsorption rate, low adsorption capacity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

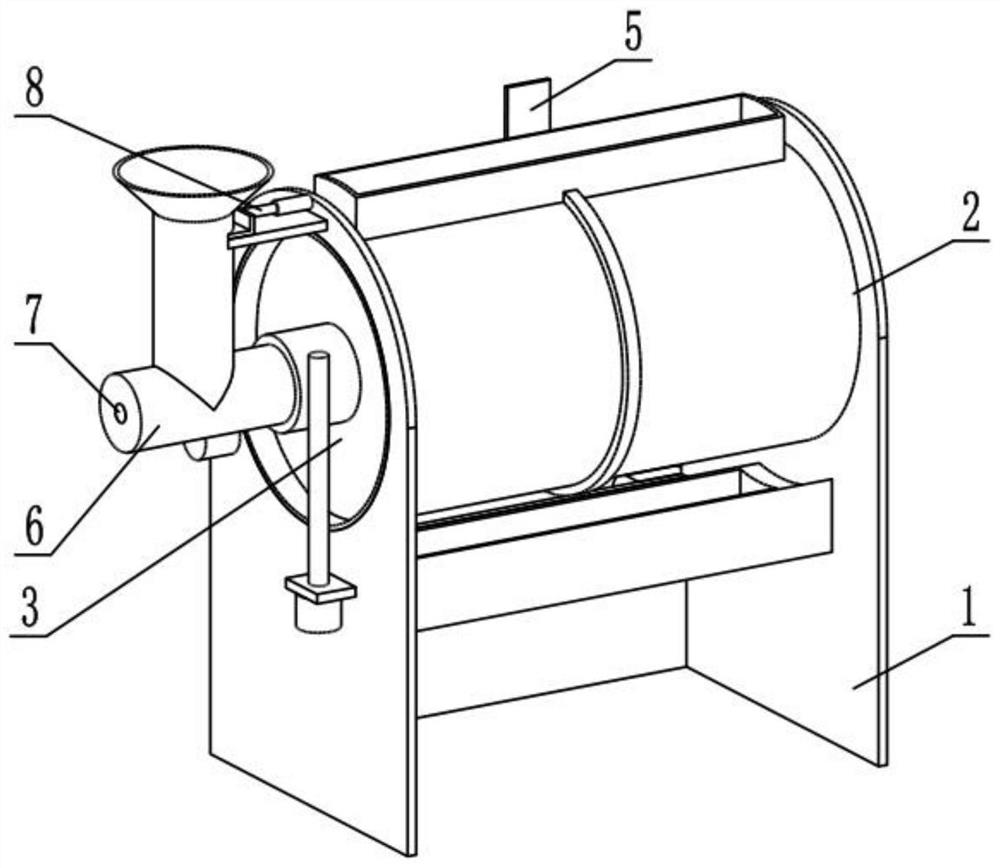

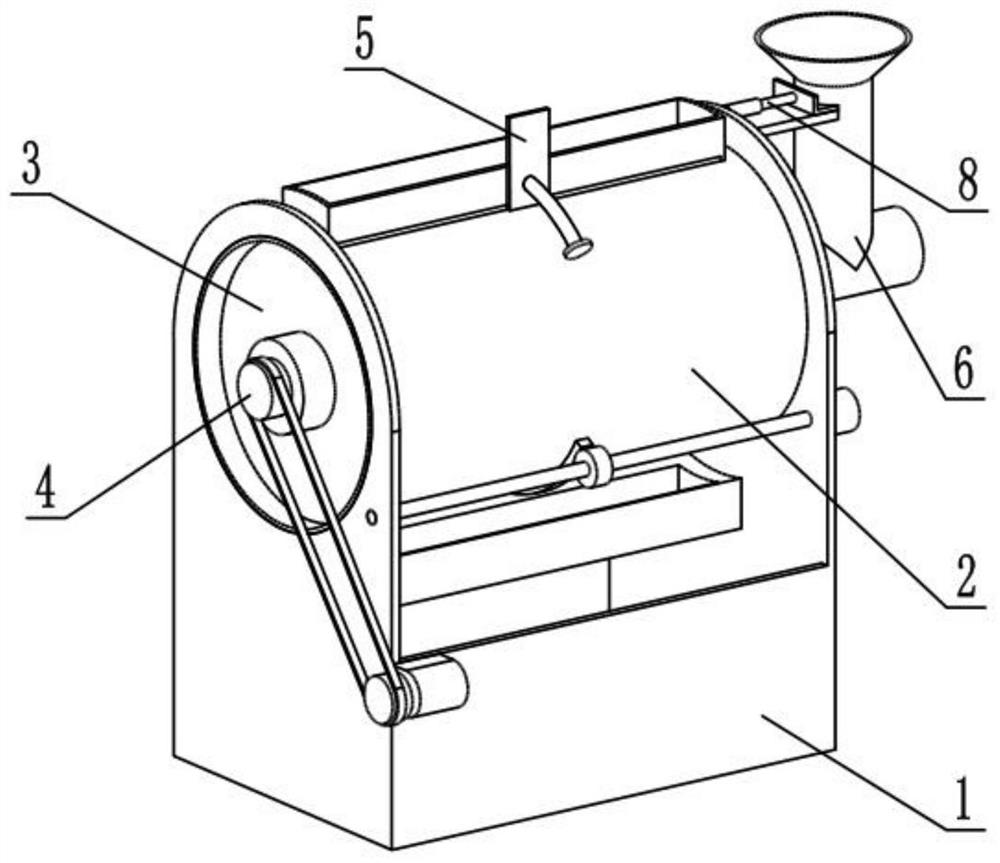

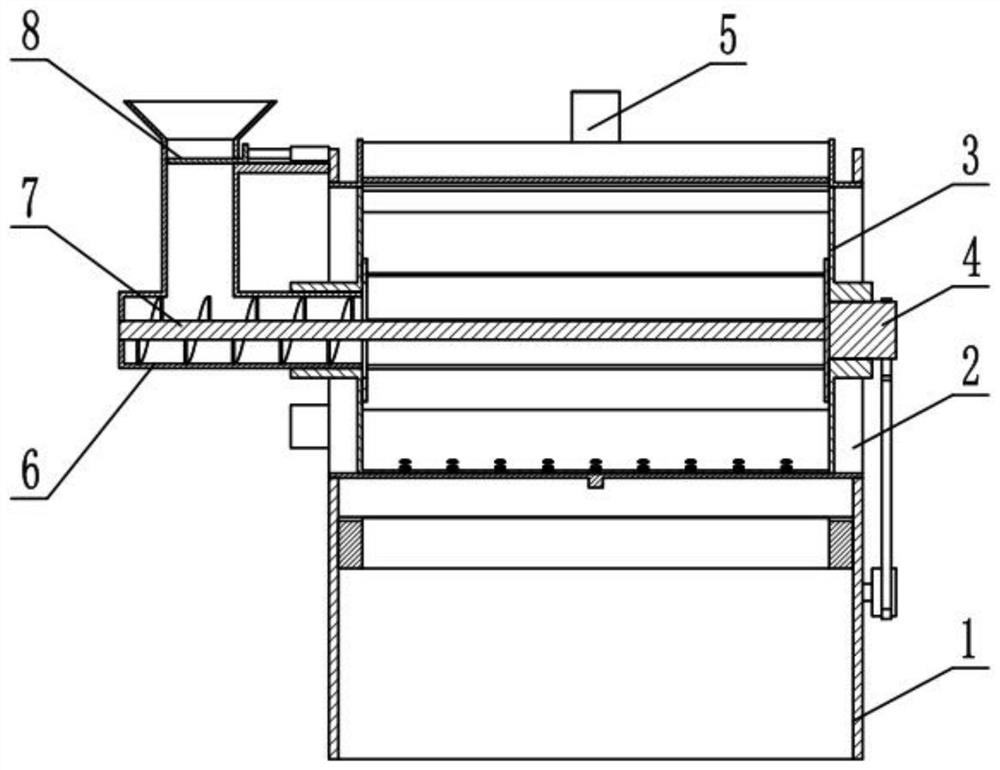

[0034] Such as Figure 1-10 Shown, a kind of inorganic heavy metal ion adsorption material preparation method, comprises the following steps:

[0035] Step 1, the first fermentation is carried out after mixing the raw materials;

[0036] Step 2, filtering the product obtained in Step 1, taking the filter residue and mixing it with other raw materials for secondary fermentation;

[0037] Step 3, filtering the product obtained in Step 2, taking the filter residue, washing it with water, and drying it naturally to obtain an inorganic heavy metal ion adsorption material;

[0038] The above-mentioned method for preparing an inorganic heavy metal ion adsorption material also involves a preparation device for an inorganic heavy metal ion adsorption material;

[0039] The preparation device for an inorganic heavy metal ion adsorption material comprises a support frame 1, a rotating outer box 2, a filter mechanism 3, a stirring mechanism 4, a box sealing mechanism 5, a feeding frame ...

specific Embodiment approach 2

[0042] Such as Figure 1-10 As shown, the support frame 1 includes a support side plate 1-1, a fixed plate 1-2, a connecting plate 1-3, a discharge seat 1-4 and a discharge hole 1-5, and the support side plate 1-1 is provided with two Two ends of the connecting plate 1-3 are respectively fixedly connected to the rear ends of the two supporting side plates 1-1, the fixed plate 1-2 is fixedly connected to one of the supporting side plates 1-1, and the discharge seat 1-4 It is fixedly connected between the two supporting side plates 1-1, and the discharge seat 1-4 is provided with a discharge hole 1-5.

specific Embodiment approach 3

[0044] Such as Figure 1-10 As shown, the rotating outer case 2 includes a rotating round pipe 2-1, a discharge pipe 2-2, an arc rod 2-3, a half gear ring 2-4 and a rotating adjustment shaft 2-5, and the rotating round pipe 2- The upper end of 1 is fixedly connected with a discharge pipe 2-2, the arc rod 2-3 is fixedly connected with the discharge pipe 2-2, and the middle part of the rotating circular pipe 2-1 is fixedly connected with a half gear ring 2-4, a half gear ring 2 -4 is connected to the transmission of the rotation adjustment shaft 2-5, the two ends of the rotation adjustment shaft 2-5 are connected to the two supporting side plates 1-1 and one end is provided with a drive motor, and the two ends of the rotation tube 2-1 are rotated They are respectively rotatably connected to the two supporting side plates 1-1, and the outer end of the discharge pipe 2-2 is rotatably connected to the inner end of the discharge seat 1-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com