A kind of preservation method of ultrafiltration membrane module

A storage method and ultrafiltration membrane technology, applied in the field of hollow fiber membranes, can solve problems affecting water flux and retention rate, unfavorable transportation, and increased weight of membrane modules, etc., to achieve enhanced sterilization and disinfection effects, good antibacterial and moisturizing effects, Apply Promising Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

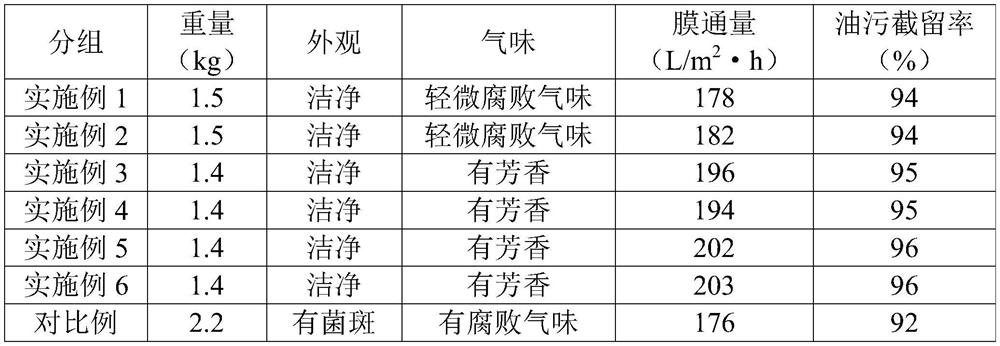

Examples

Embodiment 1

[0026] First immerse the ultrafiltration membrane module in a sodium hypochlorite solution of 50ppm available chlorine, soak for 2 hours, then soak the ultrafiltration membrane module in a sodium gluconate solution with a mass concentration of 10%, and obtain a pore-preserving treatment after soaking for 2 hours Ultrafiltration membrane module, and then fix the ultrafiltration membrane module with pore-preserving treatment on the centrifuge for centrifugal drying treatment. When the centrifugal drying is done until no obvious liquid flows out, stop the centrifugation to obtain the dried ultrafiltration membrane module. The ultrafiltration membrane module is placed in a closed container, fumigated with 100°C water vapor for 10 minutes, the ultrafiltration membrane module is taken out, and after cooling, it is vacuumed with a double-layer PE packaging bag and sealed for storage.

Embodiment 2

[0028] First immerse the ultrafiltration membrane assembly in a sodium hypochlorite solution of 60ppm available chlorine for 3 hours, then soak the ultrafiltration membrane assembly in a sorbitol solution with a mass concentration of 20%, and obtain a pore-preserving treatment after 3 hours of immersion treatment. Then fix the pore-preserving ultrafiltration membrane assembly on the centrifuge for centrifugal drying treatment. When the centrifugal drying is done until no obvious liquid flows out, stop the centrifugation to obtain the dried ultrafiltration membrane assembly. The dried The ultrafiltration membrane module is placed in a closed container, fumigated with 120°C water vapor for 20 minutes, the ultrafiltration membrane module is taken out, and after cooling, it is vacuumed with a double-layer PE packaging bag and sealed for storage.

Embodiment 3

[0030] First immerse the ultrafiltration membrane assembly in a sodium hypochlorite solution of 70ppm available chlorine, soak for 4 hours, then soak the ultrafiltration membrane assembly in a xylitol solution with a mass concentration of 30%, and obtain a pore-preserving treatment after soaking for 4 hours. Ultrafiltration membrane module, and then fix the ultrafiltration membrane module with pore-preserving treatment on the centrifuge for centrifugal drying treatment. When the centrifugal drying is done until no obvious liquid flows out, stop the centrifugation to obtain the dried ultrafiltration membrane module. The ultrafiltration membrane module was placed in a closed container, fumigated with Litsea cubeba oil vapor at 140°C for 10 minutes, and the ultrafiltration membrane module was taken out. After cooling, it was vacuumed with a double-layer PE packaging bag and sealed for storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com