Production equipment of water-based paint

A technology for production equipment and water-based coatings, applied in the field of production equipment for water-based coatings, can solve problems such as high production costs, insufficient grinding, uneven mixing of materials, etc., and achieve the effects of reducing production costs, saving production time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, those skilled in the art All other embodiments obtained by the skilled person without creative work belong to the protection scope of the present invention.

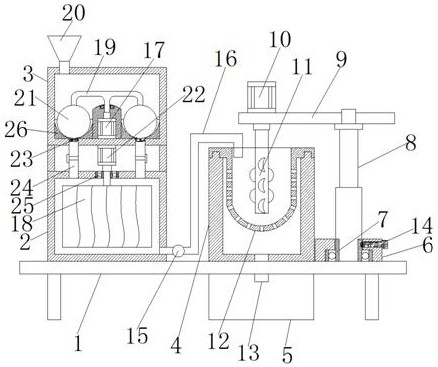

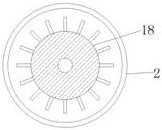

[0020] see Figure 1~2 , in the embodiment of the present invention, a kind of production equipment of water-based paint, comprises workbench 1, emulsification box 2, grinding box 3, filter box 4, material storage box 5, bearing seat 6, first bearing 7, hydraulic expansion rod 8 , crossbar 9, first motor 10, stirring paddle 11, filter cartridge 12, discharge pipe 13, fastening screw 14, water pump 15, feeding hose 16, second motor 17, runner 18, swivel frame 19, Hopper 20, grinding ball 21, third motor 22, filter screen 23, connecting pip...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap