Novel roller pass laser grinding device and operation method thereof

A laser and roll technology, applied in the field of roll grinding, can solve the problems of high labor intensity, splashing personnel, injuries and other problems of construction personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

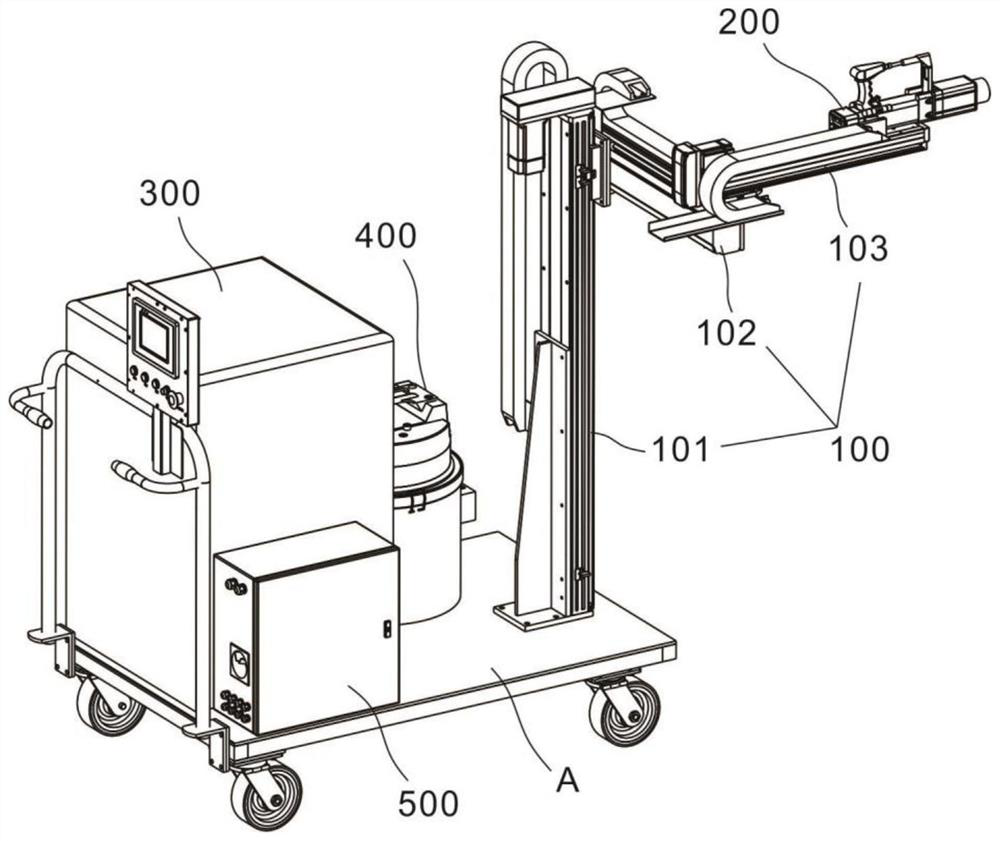

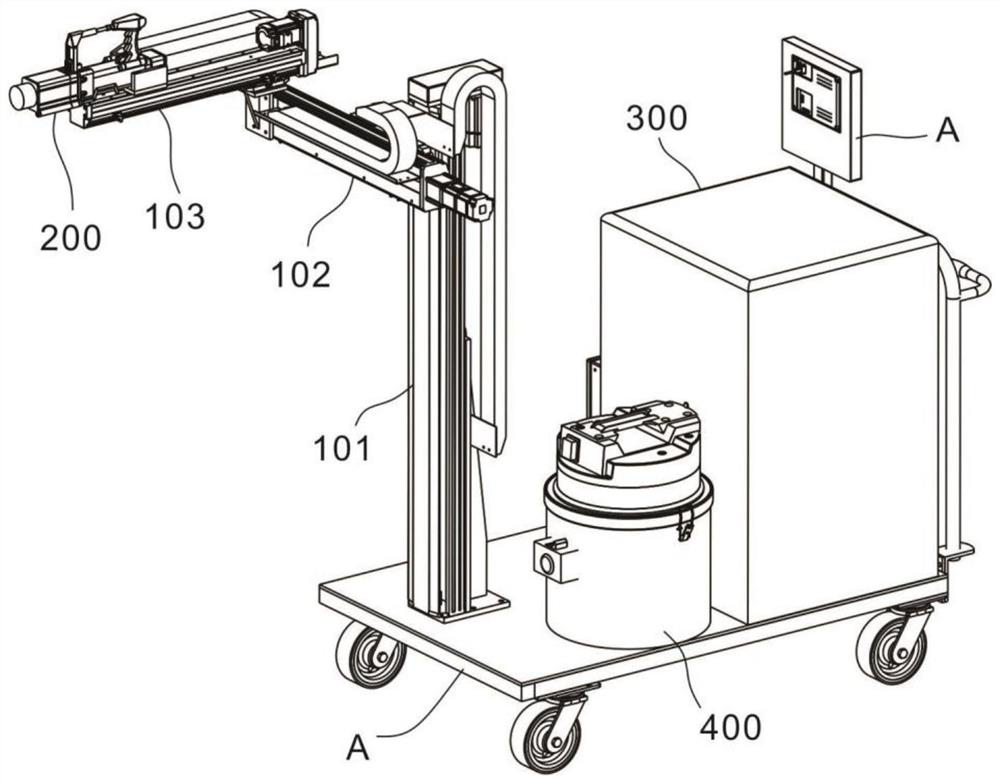

[0038] refer to figure 1 , which is the first embodiment of the present invention, provides a new type of laser grinding roll pass device, which includes a mobile platform A, a three-axis slide 100 and a laser actuator 200, wherein the three-axis slide 100 is installed on On the mobile platform A, it includes a Z-axis sliding table 101, a Y-axis sliding table 102 connected with the Z-axis sliding table 101, and an X-axis sliding table 103 connected with the Y-axis sliding table 102; the laser actuator 200 is set on the X-axis On the shaft slide table 101.

[0039] It also includes a laser polishing host 300, a dust removal device 400 and a PLC control unit 500. The PLC control unit 500 is electrically connected to the three-axis slide 100, the laser actuator 200, the laser polishing host 300, and the dust removal device 400 respectively.

[0040]Among them, the mobile platform A can be used as a platform for device installation. In this embodiment, a mobile trolley with unive...

Embodiment 2

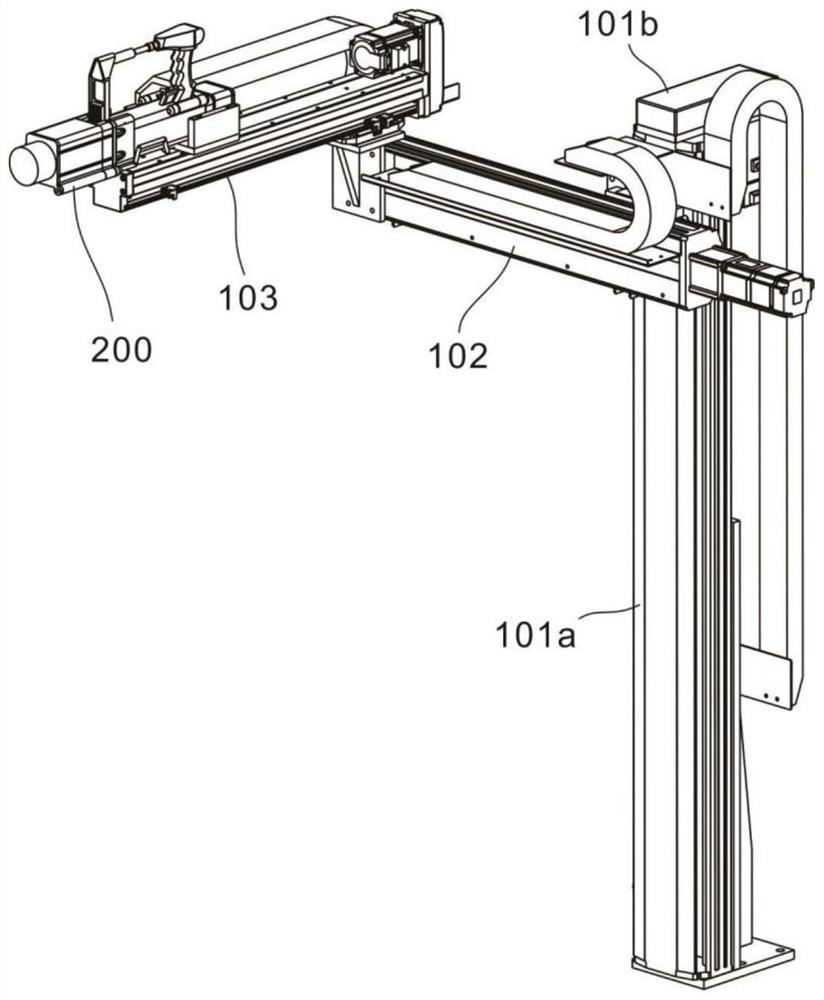

[0043] refer to figure 1 , which is the second embodiment of the present invention. This embodiment is different from the first embodiment in that: the Z-axis slide table 101, the Y-axis slide table 102 and the X-axis slide table 103 have the same structure, wherein the Z-axis slide table The table 101 includes a support tube 101a and a driving member 101b connected to an end of the support tube 101a.

[0044] The support tube 101a includes a tube body 101a-1 and a screw rod 101a-2, the screw rod 101a-2 is rotatably installed in the inner cavity of the tube body 101a-1 through a bearing; the side wall of the tube body 101a-1 is distributed along its length direction There are guide grooves 101a-11; the drive member 101b includes a drive motor 101b-1 and a differential 101b-2, the differential 101b-2 is coaxially connected to the output shaft of the drive motor 101b-1, and the differential 101b- 2 is connected with the threaded mandrel 101a-2 through a bevel gear.

[0045] Th...

Embodiment 3

[0057] refer to figure 1 , is the third embodiment of the present invention, provides a kind of operation method of novel laser grinding roll pass device, adopts the novel laser grinding roll pass device as in embodiment 1 and 2, also includes the following operation steps :

[0058] Move the device to the location where the roll tooling is stored, input the corresponding parameters in the PLC control unit 500 according to the roll model, and start the device to run;

[0059] The three-axis sliding table 100 moves, the Z-axis sliding table 101 drives the Y-axis sliding table 102 and the X-axis sliding table 103 to move to the position of the center axis of the roll, the Y-axis sliding table 102 drives the X-axis sliding table 103 to run to the roll hole surface, and the X-axis The sliding table 103 drives the laser actuator 200 to approach the hole surface of the roll;

[0060] Stop when the distance measuring sensor 601 detects the set focal length, the laser actuator 200 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com