Activated carbon-based high-concentration printing and dyeing wastewater advanced treatment and recycling equipment

A printing and dyeing wastewater and advanced treatment technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of reducing the cleanliness of wastewater and insufficient efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

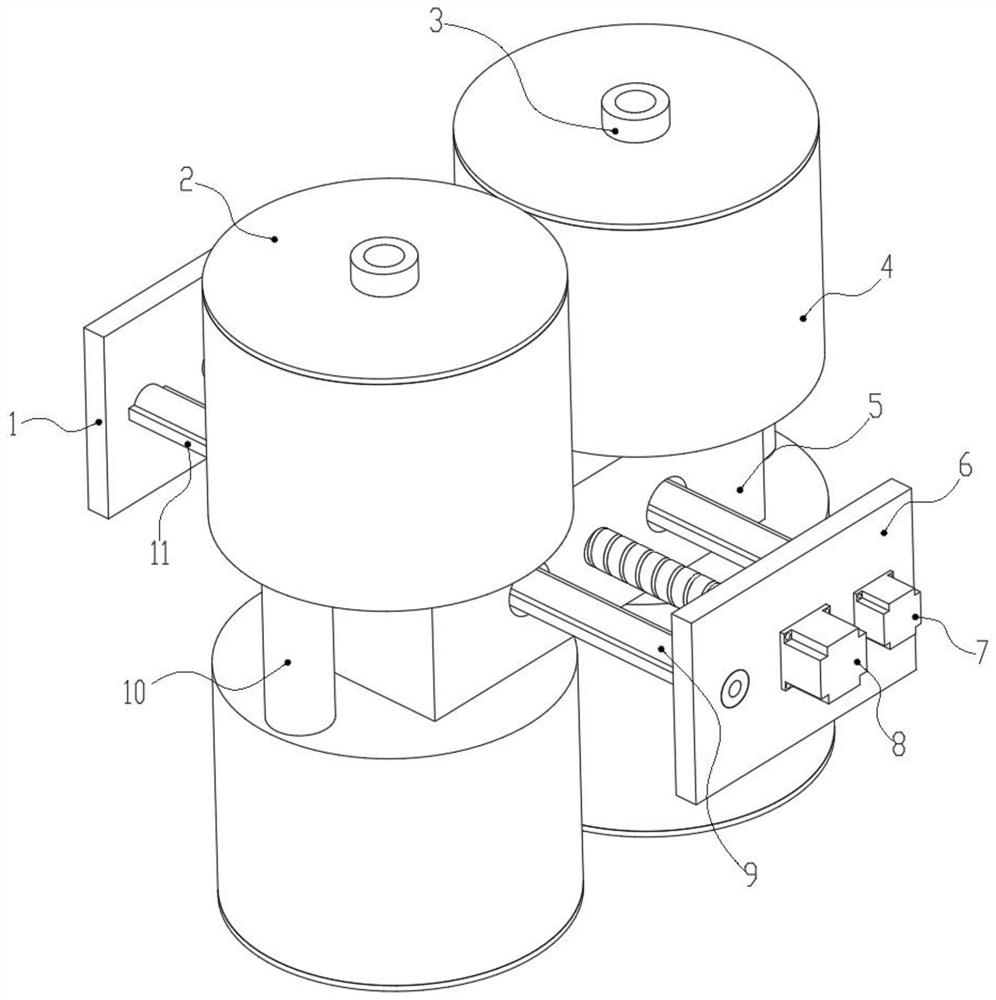

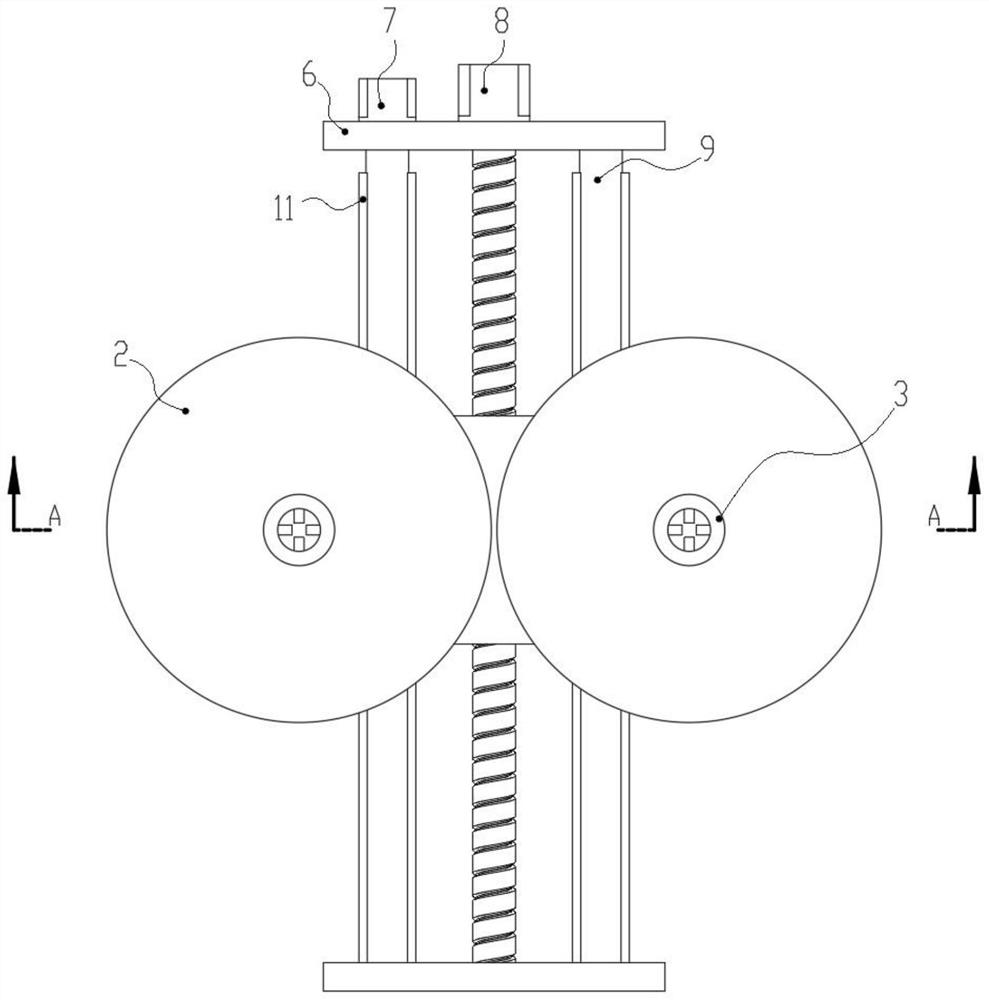

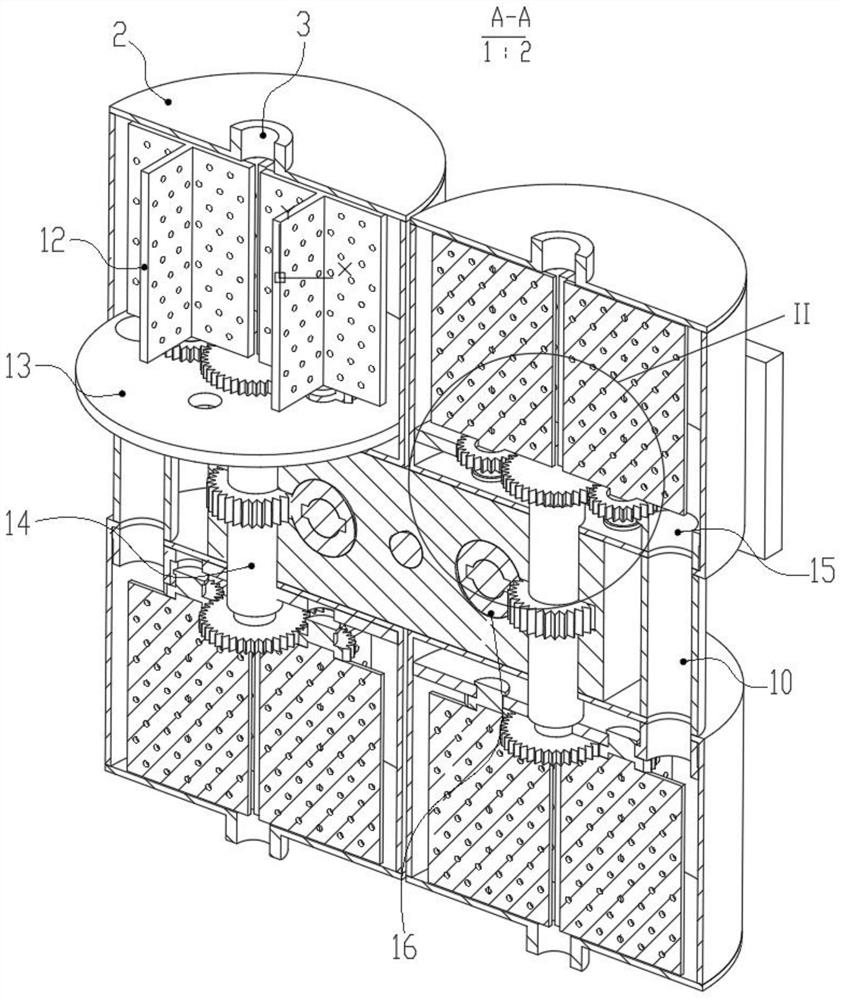

[0032] Such as figure 1 , 2, 3 and 4 show the first embodiment of the present invention: a kind of advanced treatment and recycling equipment for high-concentration printing and dyeing wastewater based on activated carbon, including a support plate 1, a connecting cover 2, a positioning joint 3, a sewage treatment tank 4, Support mechanism 5, limit support plate 6, connecting motor 7, fixed motor 8, transmission shaft 9, connecting pipe 10, guide block 11, activated carbon filter mechanism 12, sealing baffle 13, transmission mechanism 14, positioning tube 15 and connecting mechanism 16. The inner end surface of the limit support plate 6 is symmetrically rotated and clamped with the drive shaft 9 for transmission, and the side end surface of the limit support plate 6 is fixedly connected to the drive shaft 9. The end face is fixedly connected with a pulley for transmission near the inside of the limit support plate 6, and the two sets of pulleys are engaged and rotated through...

Embodiment 2

[0042] On the basis of Example 1, such as Figure 8 As shown, the side end surface of the fixed worm 161 is symmetrically fixedly connected with a positioning baffle 163 for support, and the outer end surface of the positioning baffle 163 is evenly and equidistantly fixedly connected with eight sets of limit springs 165 for buffering. A support ring 164 is fixedly connected to the center of the front end surface of 165 .

[0043] When this embodiment is in use, when the position of the support mechanism 5 is adjusted, the positioning baffle 163 can block and limit the outside of the support plate 1 and the limit support plate 6, and cooperate with the eight sets of limit springs 165 at the same time. Buffering can effectively improve the protection performance of the supporting mechanism 5 and improve the service life.

[0044] Working principle: When in use, the user can connect the external waste water delivery pipe to the positioning joint 3, and then connect the external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com