High-temperature-boiling-resistant polypropylene composite material and preparation method thereof

A technology of composite materials and polypropylene, which is applied in the field of high-temperature-resistant boiled polypropylene composite materials and its preparation, can solve problems such as failure, difficulty in passing the high-temperature boil-resistant test of spray-painted parts, and harsh test conditions, and achieve low molecular weight and low content , low catalyst residue and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

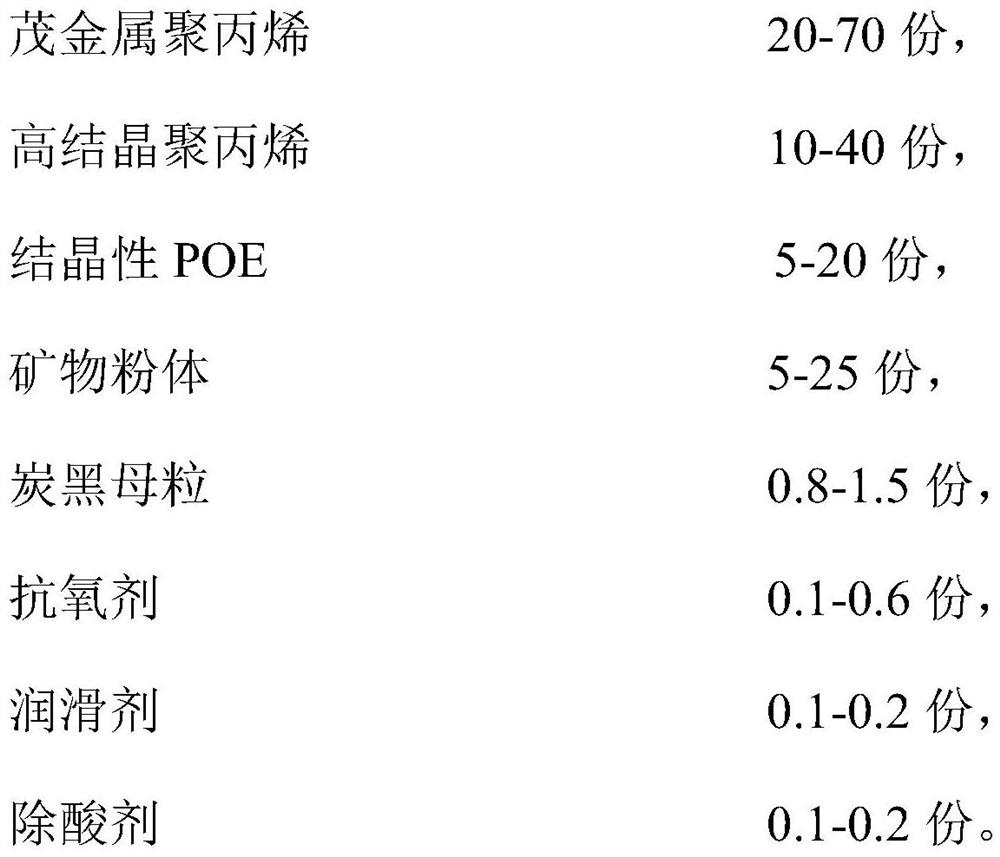

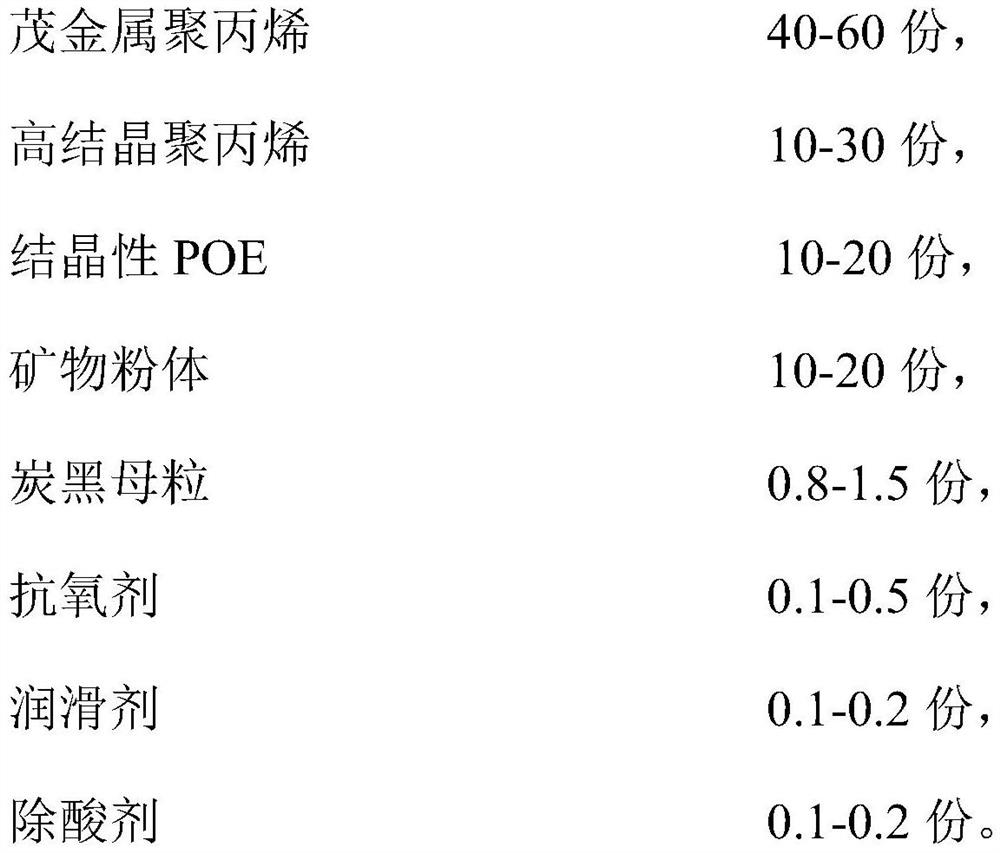

Method used

Image

Examples

Embodiment 1

[0031]A high-temperature-resistant boiled polypropylene composite material, which is made of the following raw materials: metallocene polypropylene Metocene HM640T 49kg, high crystallization polypropylene BX3900 30kg, crystallization POE ENGAGE XLT8677 10kg, talcum powder TYT-777A 10kg, carbon black masterbatch 2718 1kg, primary antioxidant AO-330 0.15kg, secondary antioxidant 168 0.3kg, acid scavenger BS-2818 0.2kg, lubricant TR451 0.2kg.

[0032] The preparation method of the high-temperature-resistant boiled polypropylene composite material comprises the following steps: mixing the metallocene polypropylene, high-crystalline polypropylene, talc powder, crystalline thermoplastic polyolefin elastomer, and carbon black masterbatch , antioxidants, lubricants, and acid removers are added to the twin-screw extruder from the main feeding port of the screw extruder, and after the processes of melt physical blending, extrusion, water cooling, water removal, pelletizing, and drying, ...

Embodiment 2

[0034] A high temperature resistant boiled polypropylene composite material, the composite material is made of the following raw materials by weight: metallocene polypropylene Metocene HM640T 49kg, high crystallization polypropylene BX3900 20kg, crystallization POE ENGAGE XLT8677 15kg, talcum powder TYT-777A 15kg, carbon black masterbatch 2718 1kg, primary antioxidant AO-330 0.15kg, secondary antioxidant 168 0.3kg, acid scavenger BS-2818 0.2kg, lubricant TR451 0.2kg.

[0035] The preparation method of the high-temperature-resistant boiled polypropylene composite material is the same as that in Example 1.

Embodiment 3

[0037] A high temperature resistant boiled polypropylene composite material, the composite material is made of the following raw materials by weight: metallocene polypropylene Metocene HM640T 49kg, high crystallization polypropylene BX3900 10kg, crystallization POE ENGAGE XLT8677 20kg, talcum powder TYT-777A 20kg, carbon black masterbatch 2718 1kg, primary antioxidant AO-330 0.15kg, secondary antioxidant 168 0.3kg, acid scavenger BS-2818 0.2kg, lubricant TR451 0.2kg.

[0038] The preparation method of the high-temperature-resistant boiled polypropylene composite material is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com