A blast furnace blowing device

A technology of injection device and blast furnace, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve the problems of reducing the utilization rate of waste plastics, blockage of feeding pipes, and difficult to clean up feeding pipes, so as to improve the effect and improve the utilization rate. rate, the effect of strengthening the detachment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

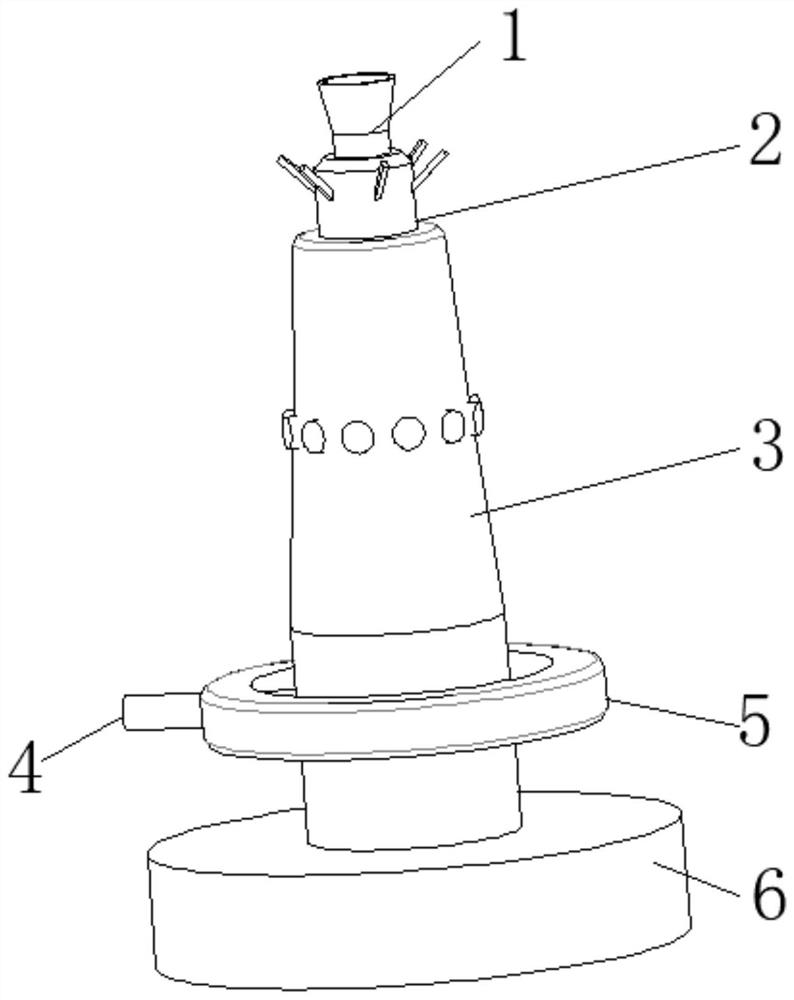

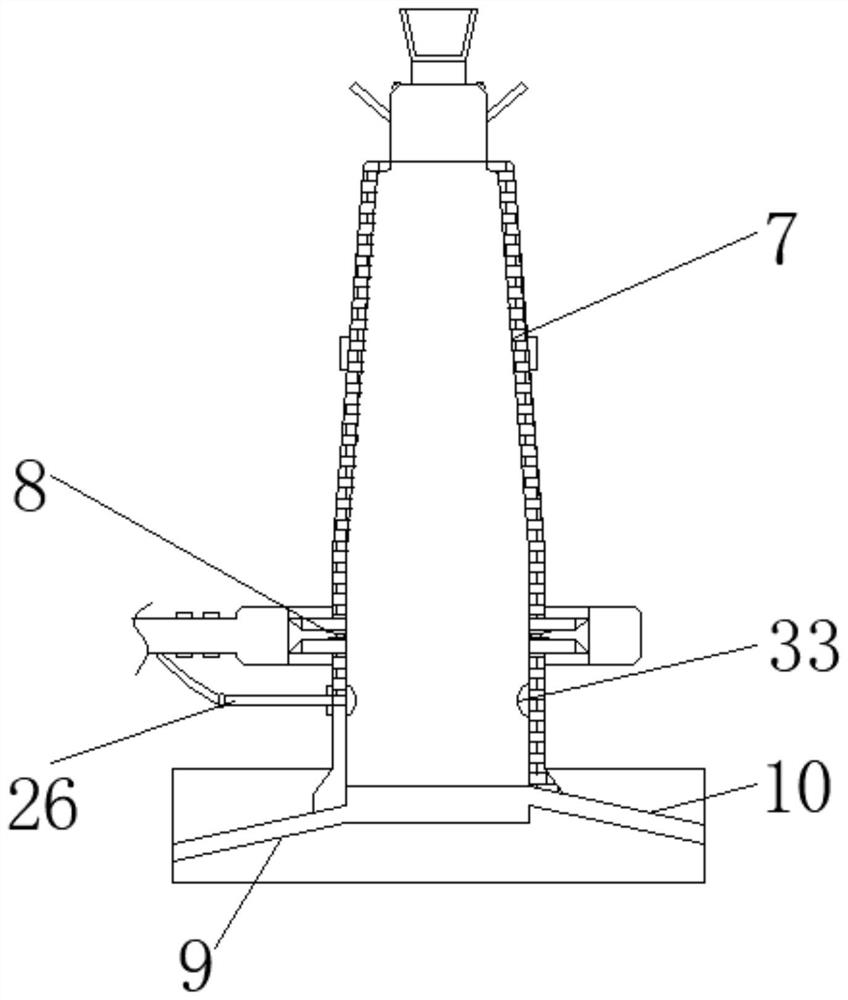

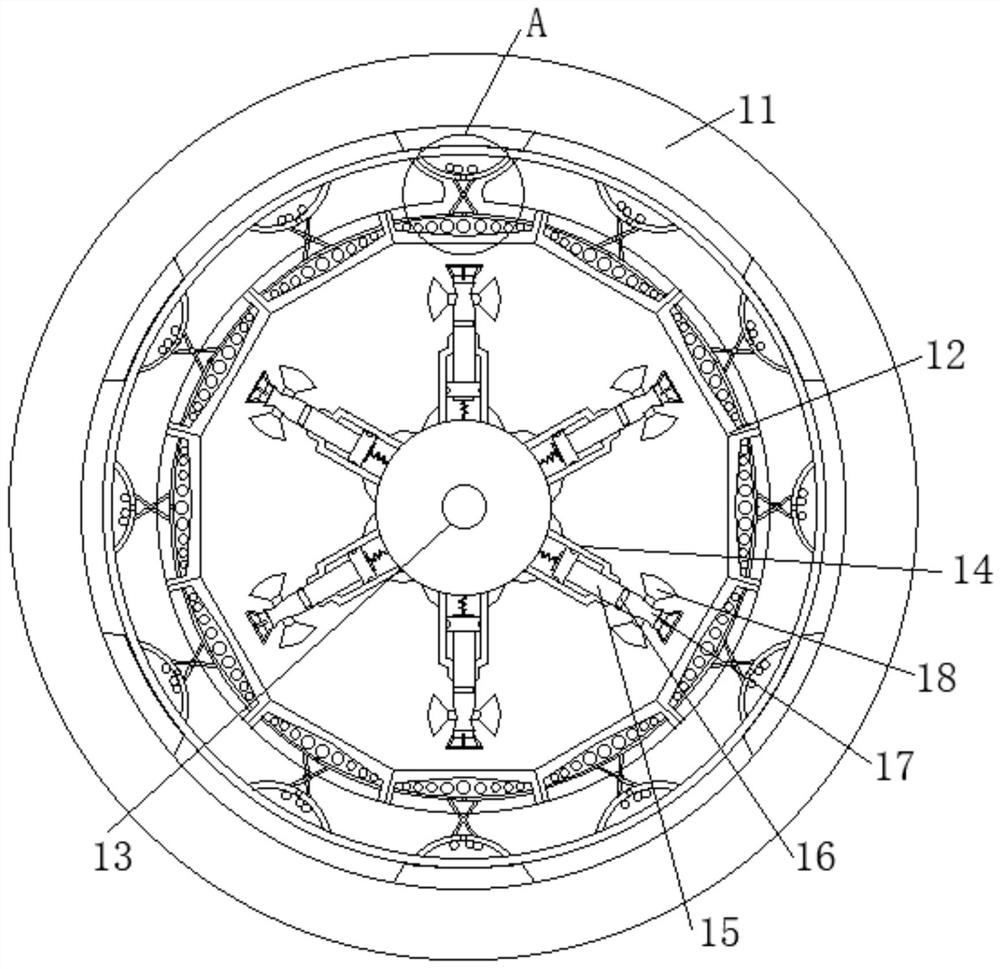

[0027] like Figure 1-7As shown, the embodiment of the present invention provides a blast furnace blowing device, including a feeding hopper 1, a filter cylinder 2, an outer layer 3, a feeding pipe 4, a fixed plate 5 and a base 6, and the filter cylinder 2 is arranged at one end of the outer layer 3. The outer wall, the feeding hopper 1 is arranged above the filter cylinder 2, the feeding hopper 1 is communicated with the filter cylinder 2, the inner wall of the outer layer 3 is provided with fire-resistant and heat-resistant bricks 7, and the fixing plate 5 is arranged on the outer wall of the outer layer 3. The fixing plate 5 is provided with an installation groove, and the inner wall of the installation groove is provided with a spray gun 8, the material conveying pipe 4 is communicated with the spray gun 8, the base 6 is arranged on the outer wall of the bottom end of the outer layer 3, and one side of the base 6 is provided with a discharge port 9, The other side of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com