Enzyme powder capable of replacing pumice stone as well as preparation method and application of enzyme powder

A technology of enzyme powder and pumice, which can be used in dyeing, textiles and papermaking, and can solve problems such as damage to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

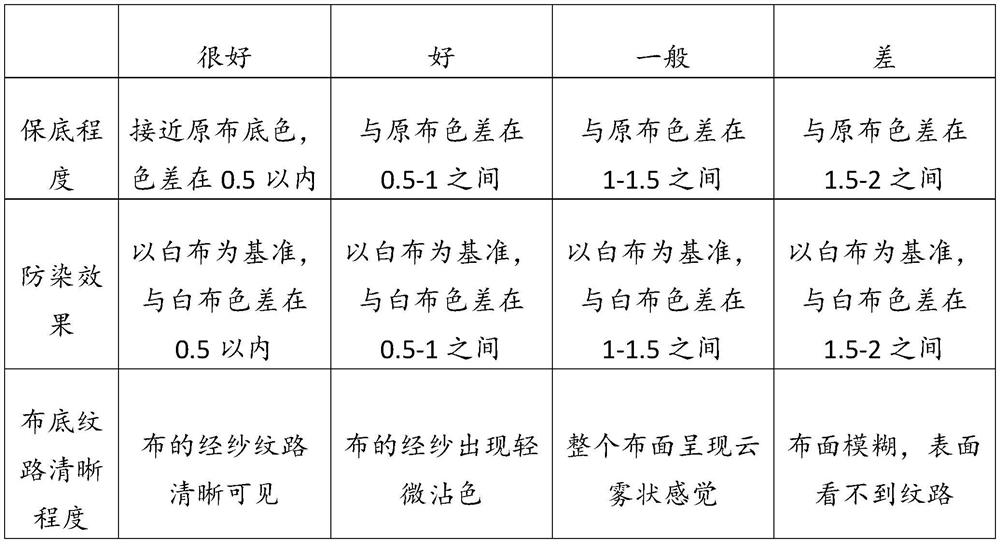

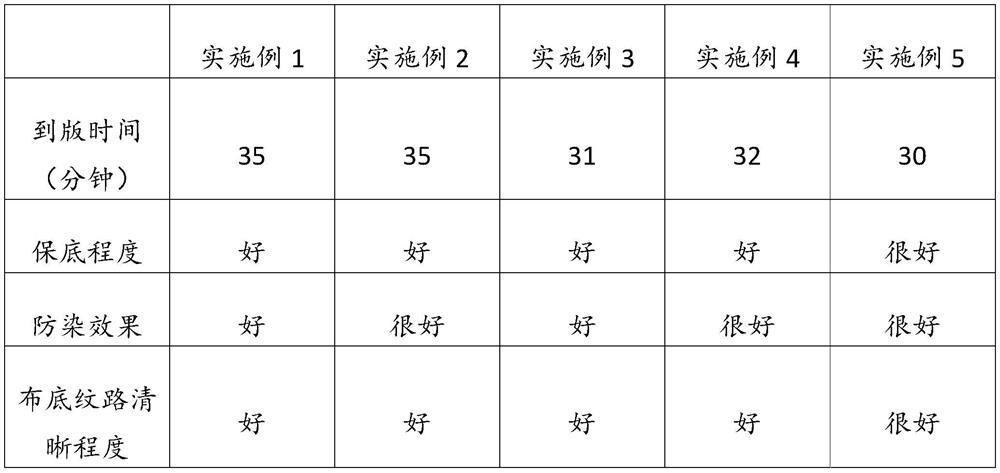

[0024] After weighing according to the components and weight parts described in Table 1, the preparation method of the enzyme powder described in embodiment 1-5, comprises the steps: biological enzyme, buffering agent, resist powder, printing paste, cold The bleaching enzyme, film, filler and dyestuff are mixed uniformly, and the enzyme powder is obtained by discharging, wherein, the film has been pulverized into powder before use.

[0025] Simultaneously, the application sets comparative examples 1-9, and the comparative examples of specific enzyme powder are as follows:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com