A testing device for the deformation of metal casing during the curing process of cement slurry

A technology for cementing cement slurry and metal casing, applied in the field of oil and gas well cementing, can solve the problems of casing damage, limited repair effect, easy deformation, etc., achieve good thermal and gas tightness, and avoid casing deformation. Damage and the effect of solving casing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below according to the accompanying drawings, so that those skilled in the art can understand the present invention. However, it should be clear that the present invention is not limited to the scope of specific implementations. For those of ordinary skill in the art, as long as various changes are within the spirit and scope of the present invention defined and determined by the appended claims, they are all within the scope of protection. List.

[0030] see figure 1 , figure 2 .

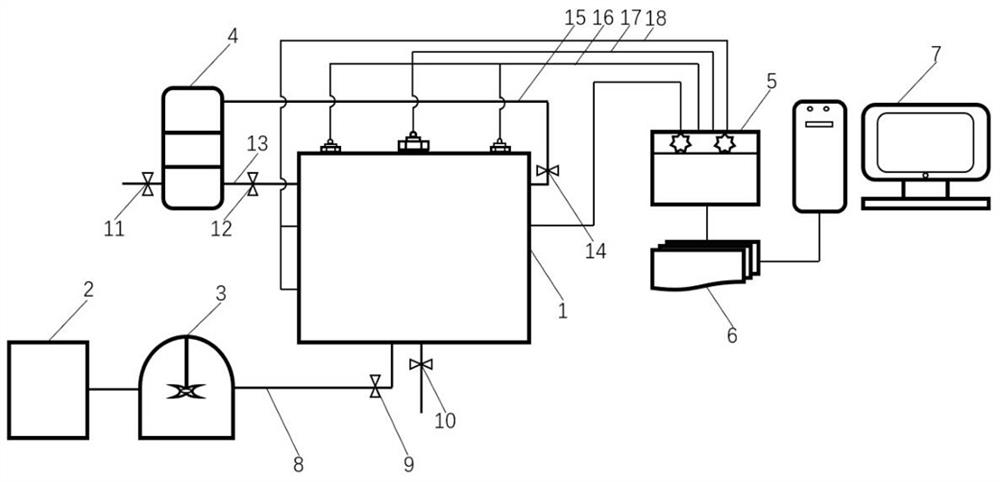

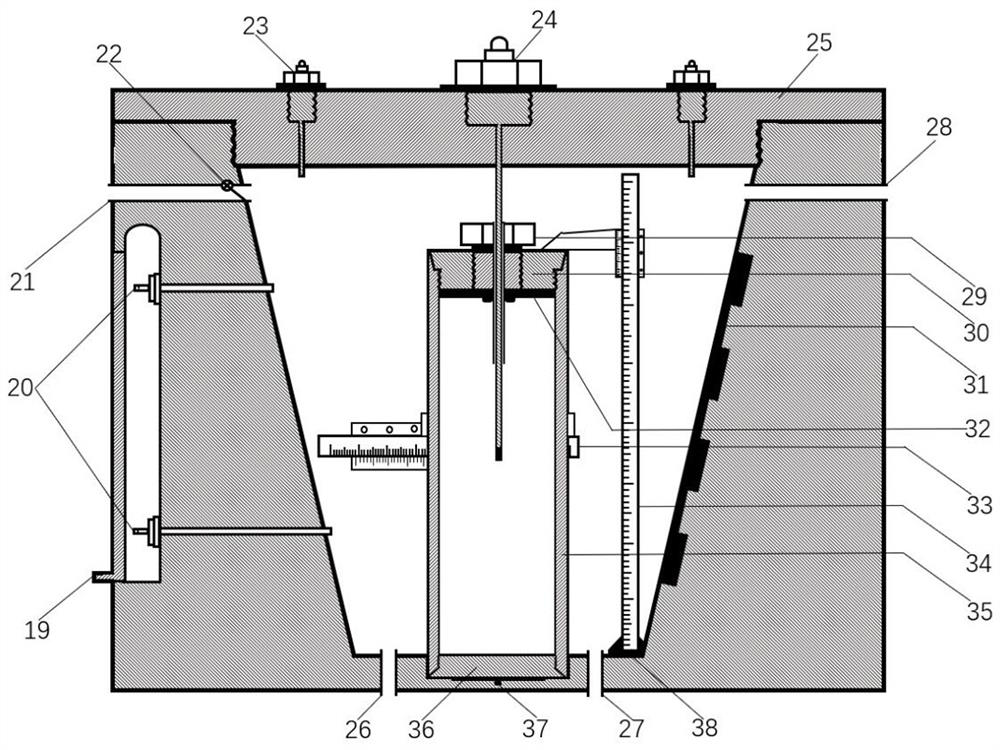

[0031] A testing device for the amount of deformation of a metal casing during the cementing process of cement slurry, including a high-temperature autoclave 1, an air compression pump 2, a cement slurry mixing storage container 3, a hydraulic booster 4, a casing deformation measuring ruler, and a temperature and pressure Control panel 5, data processing system 6 and computer and data display system 7.

[0032] The left end of the high-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com