Preparation method and system of mixed gas for preparing intermittent hypoxia animal model

An animal model and preparation system technology, applied in the field of medical experiments, can solve the problems of incapability of animal modeling, high modeling cost, and low success rate, and achieve the effects of high modeling efficiency, improved modeling efficiency, and high success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

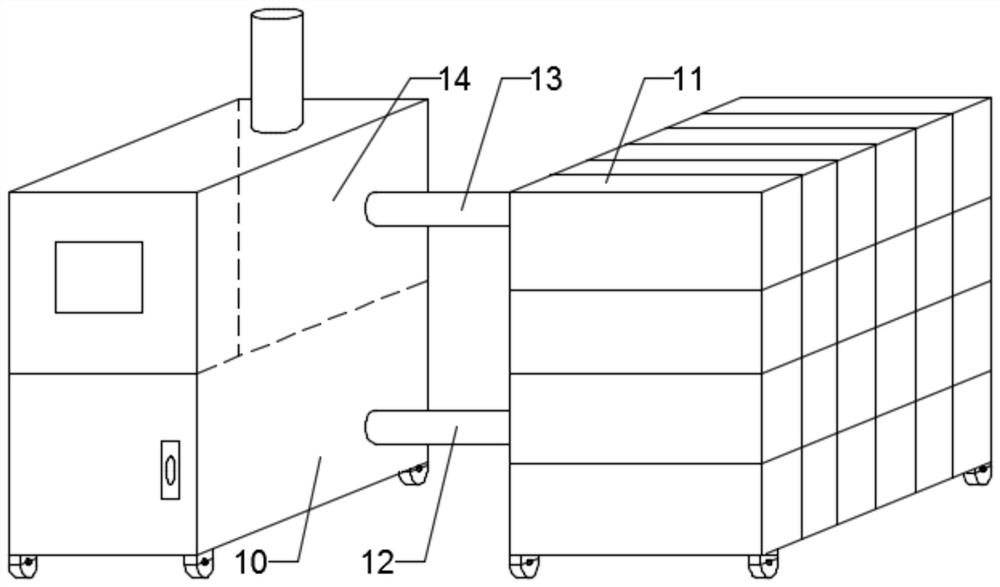

[0042]Such asfigure 1 withFigure 9 As shown, a intermittent hypoxic animal model preparation system includes a gas mixing apparatus 10 that produces a low oxygen gas and a cage box 11 for placing an experimental animal via a gas mixing device 10.

[0043]The present invention can shorten the gas mixed time by inputting the gas in the gas mixing device 10 to the cage box 11, and can shorten the time of the gas mixing, and it is originally mixed in the sealing chamber of the feeding experimental animal. When the gas oxygen concentration is adjusted, since the gas mixing is performed directly in the sealing case, the present invention will affect the survival of the experimental animals, and the present invention has previously modulated oxygen concentrations of the mixed gas, and the adjustment of mixed gas inputs the experimental animal. In the cage box 11, it is more advantageous to carry out animal modeling, high moderate efficiency, high success rate.

[0044]Preferably, the exhaust gas...

Embodiment 2

[0052]In this example, the present invention is further optimized for the present invention.

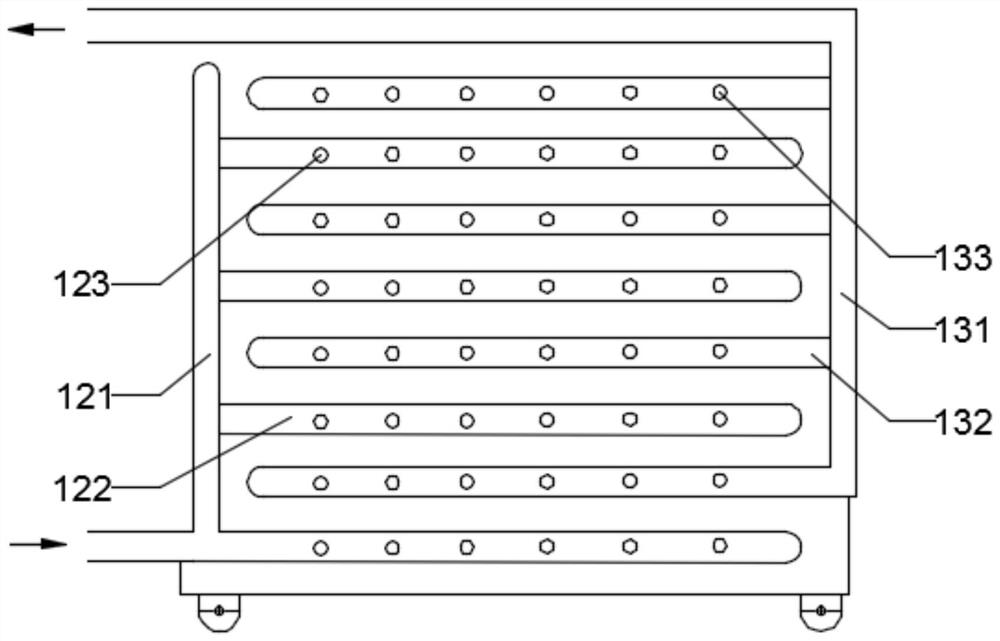

[0053]Such asFigure 2-6 As shown, the mixed intake pipe 12 includes an intake main pipe 121, and there is a plurality of intake branch 122 on the intake main pipe 121, and there is a plurality of intake pipe 123, and the air supply pipe 123 is vertical. The horizontal plane of the intake main pipe 121 and the intake branch 122;

[0054]The exhaust gas air tube 13 includes a venting main pipe 131, and a plurality of air branch 132 are connected to the air, each of which is provided with a plurality of air nozzles 133, and the air nozzle 133 is perpendicular to the perpetrator 131 and the air branch 132. level;

[0055]Among them, the number and pitch of the air supply nozzle 123 on each intake branch 122 equal to the number and spacing of the outlet nozzle 133 on each air branch 132, and the number of cage boxes 11 is plural, and each cage box 11 is All of the air intake and outlet, the intake branc...

Embodiment 3

[0061]In this example, the present invention is further optimized for the present invention.

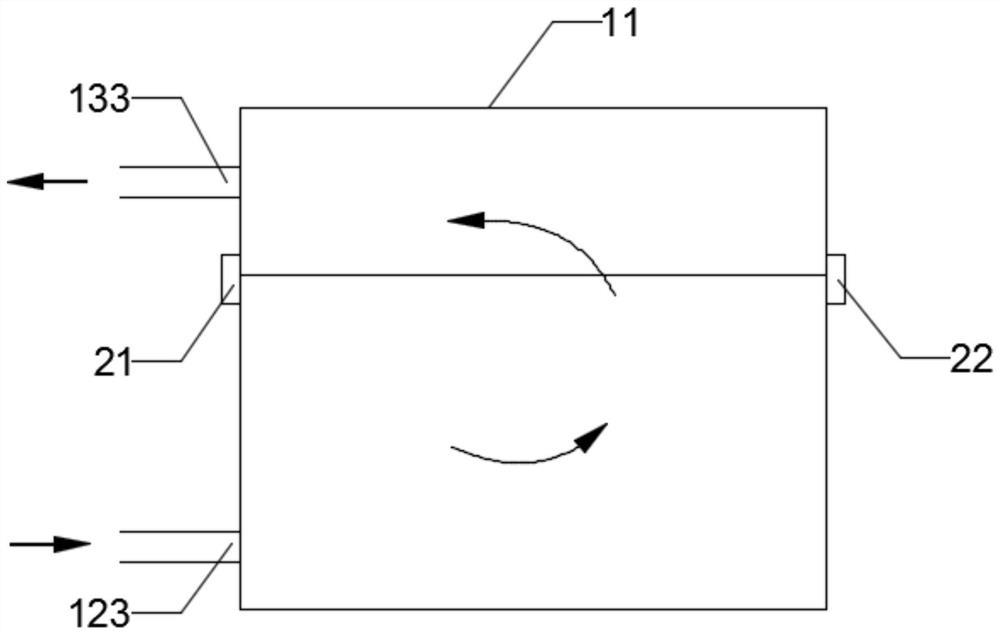

[0062]Such asFigure 3 - Figure 8As shown, the intake port and the air port are connected to the cage 15, and the cage 15 is opened from one end of the cage box 11, and the pass groove 16 is provided with a spring passage closure 17, the spring is closed. The upper end of the 17 is connected to the cage 15.

[0063]When the present invention, the intake nozzle 123 and the air supply nozzle 133 pass through the pass groove 16 corresponding to the cage 15, and the spring passage closure 17 is pushed forward, and the cage box 11 is supplied and ventilated, and the cage box is required. 11 When the seal is sealed, return the inlet nozzle 123 and the air nozzle 133, and the spring passage closing piece 17 is reset, that is, the seal of the cage box 11 can be completed.

[0064]It should be noted that the intake nozzle 123 and the air supply can be used to complete the operation of the inlet 123 and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com