Sandy stuffing mixing preparation equipment and use method thereof

A filling and sandy technology, which is applied in mixers, chemical instruments and methods, shaking/oscillating/vibrating mixers, etc., can solve the problem of uneven mixing of bean paste and additives, poor mixing effect, and affecting sandy fillings Taste and quality issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

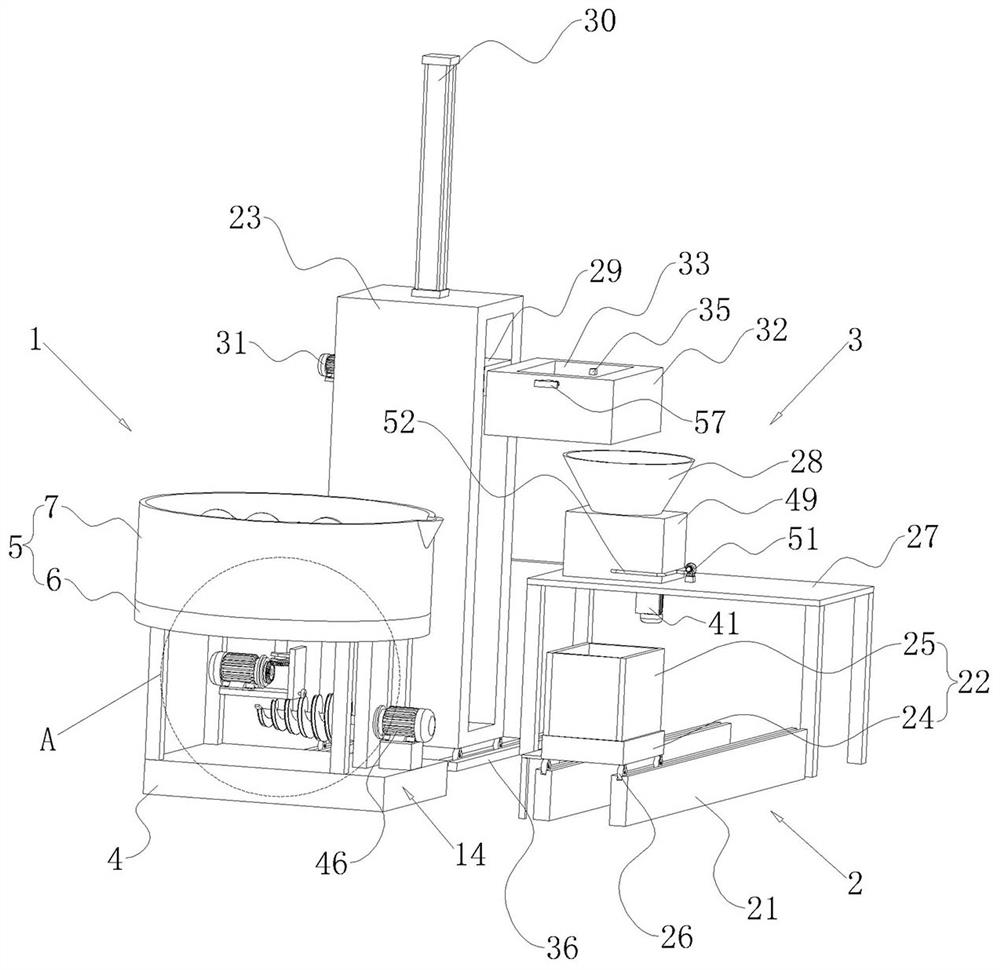

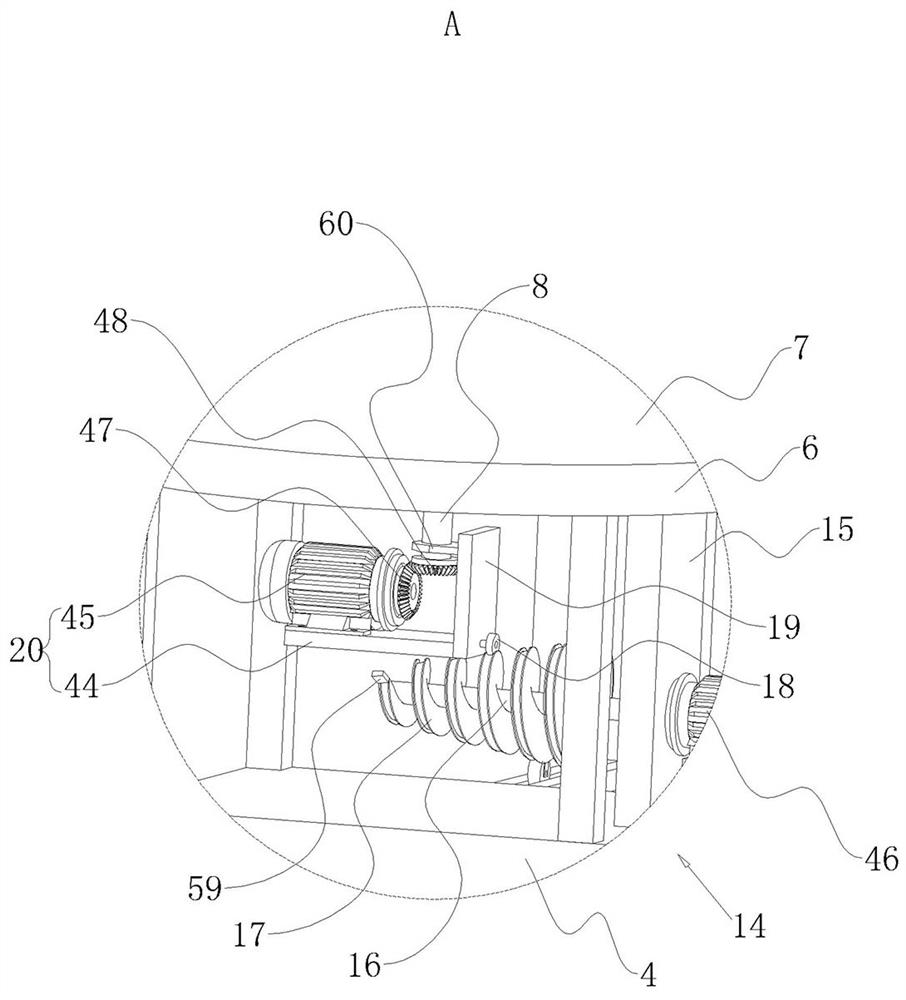

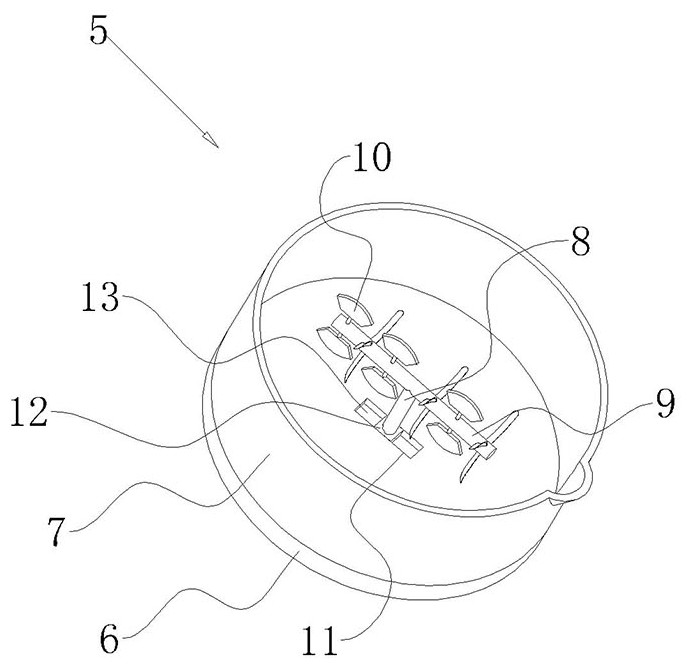

[0043] refer to figure 1 , a sandy stuffing mixing preparation equipment, including a stir-frying device 1, a conveying device 2 and a feeding device 3, the conveying device 2 is located between the stir-frying device 1 and the feeding device 3, and the stir-frying device 1 includes a positioning plate 4 and the frying pan 5 positioned on the positioning plate 4; the frying pan 5 includes the bottom of the pot 6 and the wall of the pot 7, the bottom of the pot 6 is a flat disc shape, the wall of the pot 7 is fixed along the outer ring surface of the bottom of the pot 6, and the wall of the pot 7 is Cylindrical. The four end corners of the upper end face of the positioning plate 4 are fixedly connected with a support frame, and the upper end of the support frame is fixedly connected with the lower end surface of the bottom of the pot 6. There is a certain space. Add additives such as bean paste and sugar into the frying pan 5 of the stir-frying device 1, stir-fry the mixed ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com