Automatic system for secondary trowelling of prefabricated house wallboard module slurry

An automated system and assembly technology, applied in the fields of machinery and cement casting products, can solve the problems of high labor intensity, excessive cement slurry overflow, and work efficiency that cannot meet on-site production, achieving good product consistency and preventing excess material. The effect of overflow and fast and stable process rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

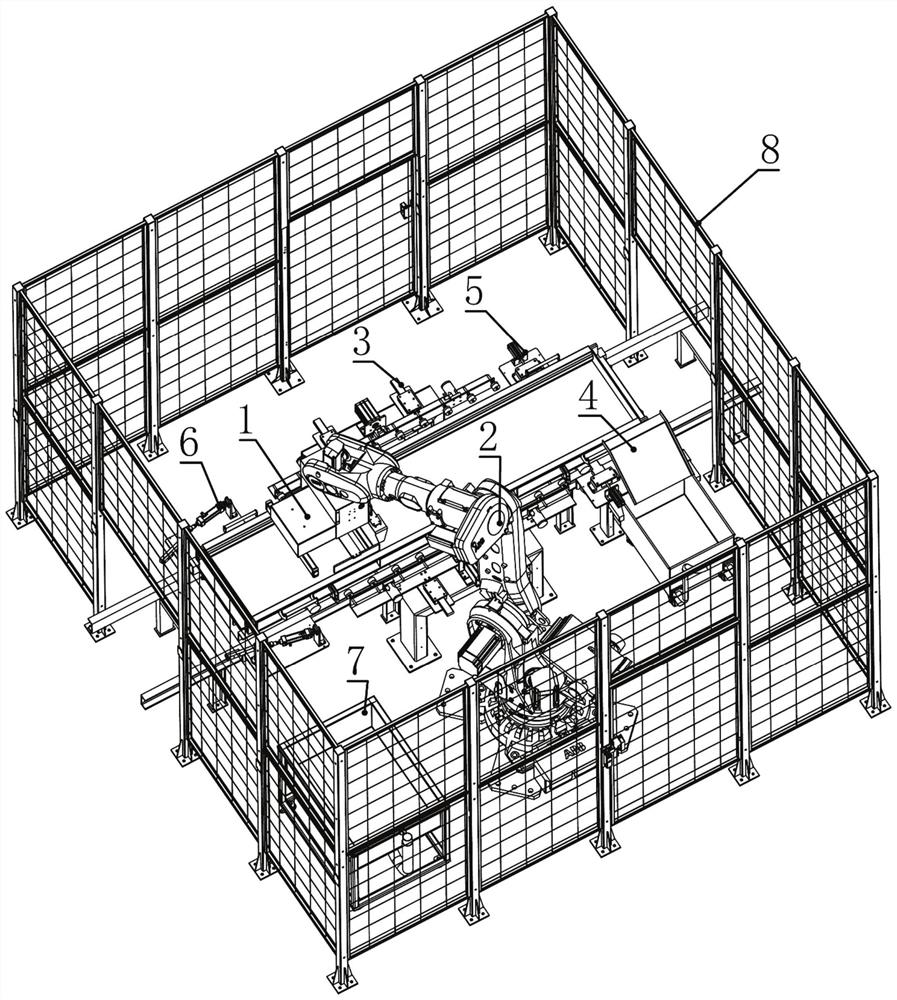

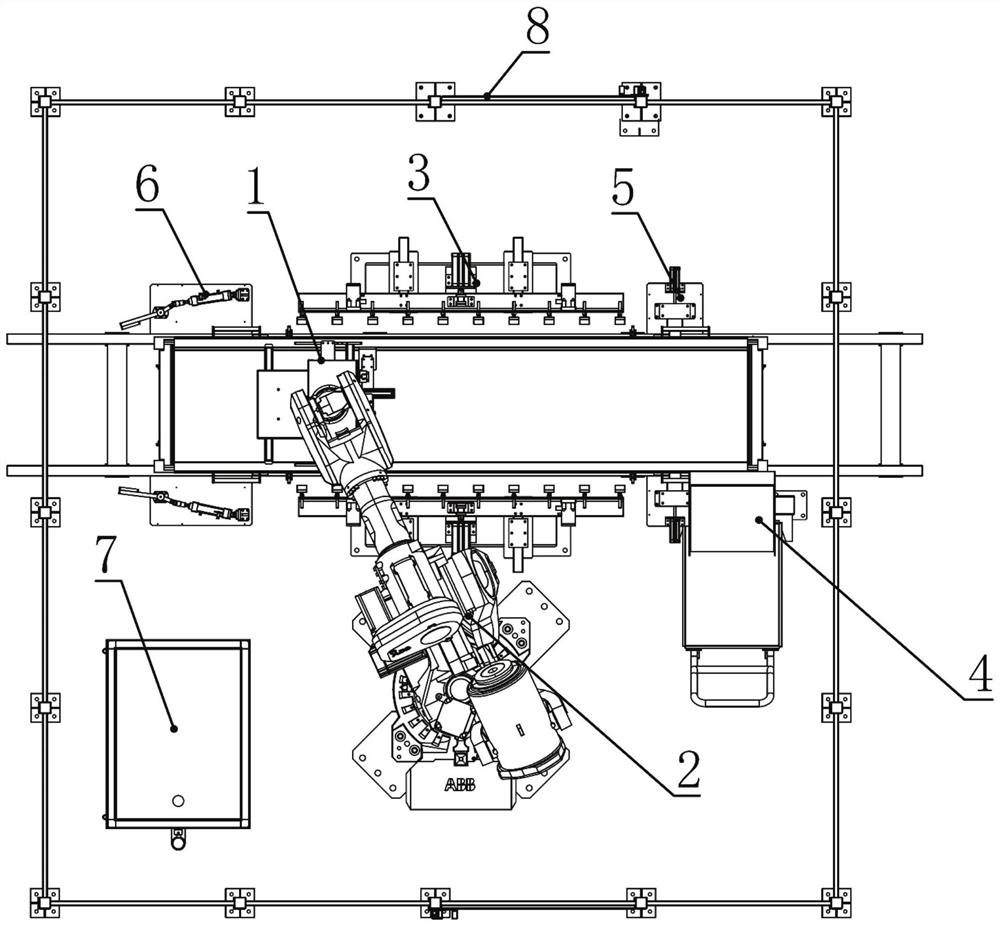

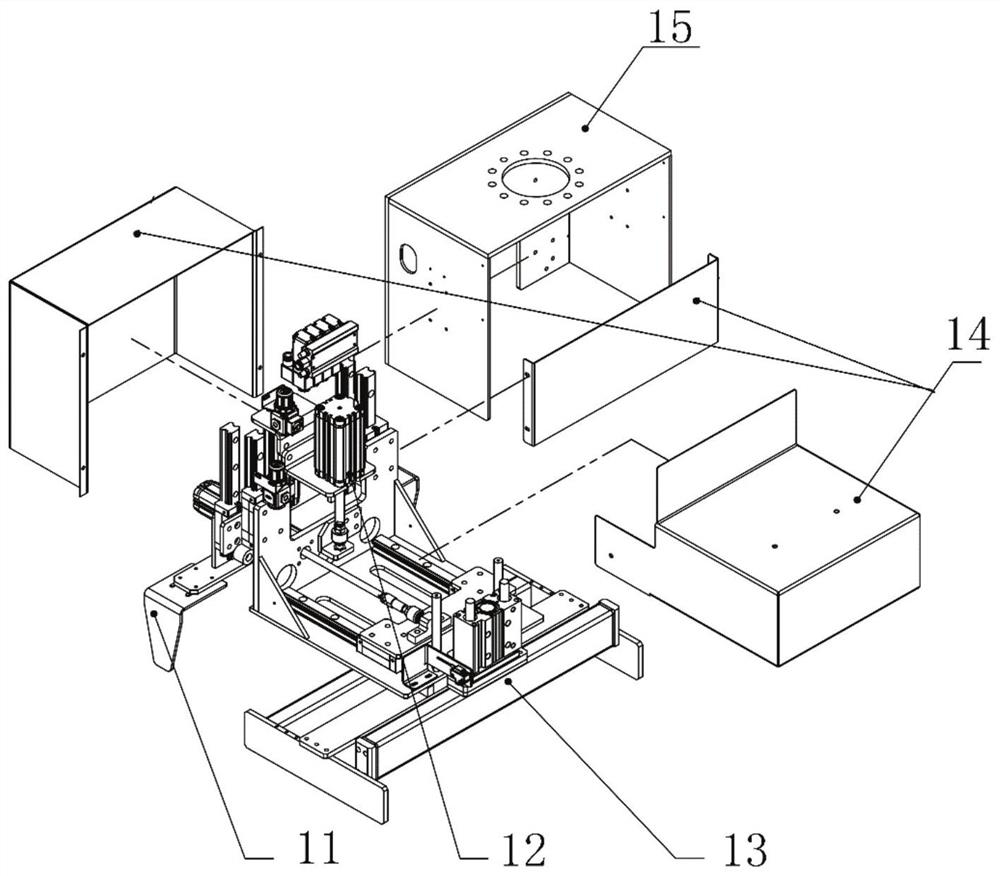

[0050] The automatic system for secondary troweling of the prefabricated house wall panel module slurry of the present invention includes a troweling manipulator device 1, a six-axis robot 2, a vibrating exhaust device 3, a residual material recovery device 4, and a mold vehicle positioning device 5 and the mold car clamping device 6, the smoothing manipulator device 1 is installed on the six-axis robot 2, the vibration exhaust device 3 includes 2 groups, which are respectively placed on both sides of the mold car, and the remaining materials are recovered The device 4 is installed on one side of the mold car, the mold car positioning device 5 includes 2 groups, and is placed on the front end of the mold car to realize positioning, and the mold car clamping device 6 includes 2 groups, and is placed on the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com