Signal device for fire-fighting lifesaving

A signal device and fire protection technology, applied in transportation and packaging, electrical equipment structural parts, cooling/ventilation/heating renovation, etc., can solve the problems of inconvenient cooling, inconvenient cooling of signal terminal equipment, poor signal reception performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

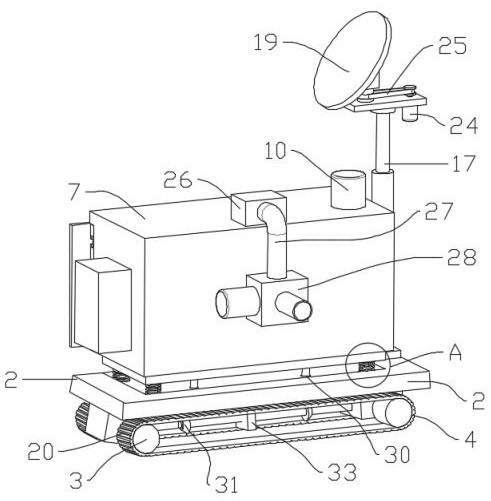

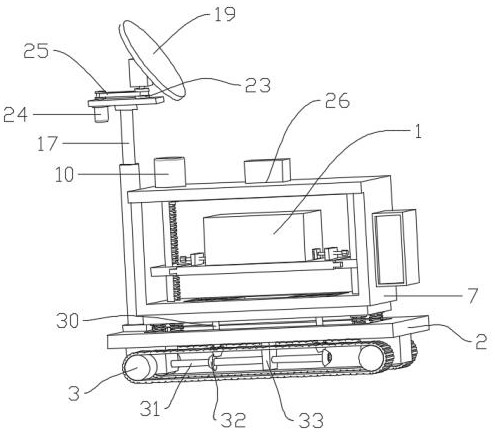

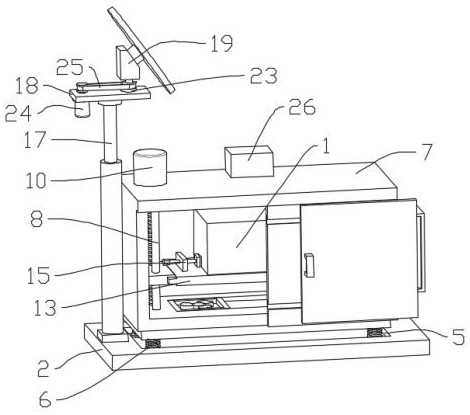

[0040]A signal device for fire fighting and lifesaving, comprising a signal terminal device 1 and a base plate 2 for installing the signal terminal device 1, two symmetrical drive wheels 3 are fixedly installed on the lower surface of the base plate 2, and the two drive wheels 3 are fitted with Two crawler belts 4, the upper surface of the bottom plate 2 are provided with installation grooves 5, and a plurality of shock absorbing mechanisms 6 are fixedly installed in the installation grooves 5, and a protective box 7 is installed on the upper ends of the plurality of shock absorbing mechanisms 6, and the inside of the protective box 7 The first mobile mechanism 8 and the second mobile mechanism 9 are fixedly installed, and the first mobile mechanism 8 and the second mobile mechanism 9 have the same structure. On the upper surface of the protective box 7, the first servo motor 10 is fixedly installed, and the first servo motor 10 The output shaft of the output shaft is connected...

Embodiment 2

[0051] The difference from Example 1 is: the surface of the protective box 7 is coated with a layer of anti-rust coating, wherein the preparation process of the anti-rust coating is as follows:

[0052] S1: According to the mass ratio, mix 4 parts of phosphoric acid and 6 parts of aluminum powder and stir quickly to make it fully react until the aluminum powder is completely dissolved;

[0053] S2: Cool to room temperature to reach semi-finished product reserve liquid;

[0054] S3: add 1 part of agar, 2 parts of acetate and 7 parts of water to the semi-finished stock solution obtained in S2, stir and mix, heat until completely melted, and slowly add to obtain mixture A;

[0055] S4: Continue stirring and adding the mixture A, then add bentonite and talc and continue stirring for 30 minutes.

Embodiment 3

[0057] The difference from Example 2 is: the surface of the protective box 7 is coated with a layer of anti-rust coating, wherein the preparation process of the anti-rust coating is as follows:

[0058] S1: According to the mass ratio, mix 5 parts of phosphoric acid and 7 parts of aluminum powder and stir quickly to make them fully react until the aluminum powder is completely dissolved;

[0059] S2: Cool to room temperature to reach semi-finished product reserve liquid;

[0060] S3: Add 2 parts of agar, 3 parts of acetate and 8 parts of water to the semi-finished product stock solution obtained in S2, stir and mix, heat until completely melted, and slowly add to obtain mixture A;

[0061] S4: Continue stirring and adding the mixture A, then add bentonite and talc and continue stirring for 40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com