Efficient coal slime gas dissolving and dewatering process

A technology of coal slime water and dissolved air, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of high water holding capacity, low calorific value, fine particle size, etc., and achieve filter press efficiency Improvement, dehydration effect improvement, filter press effect improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

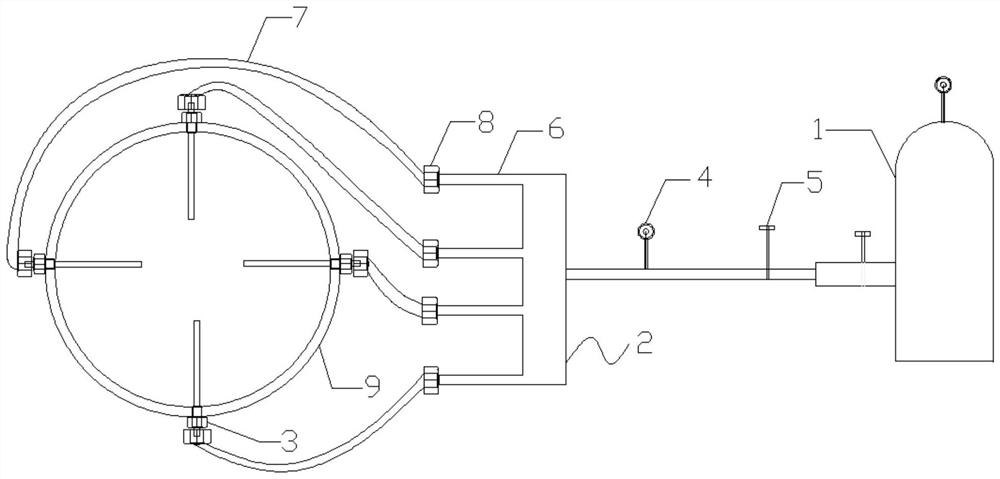

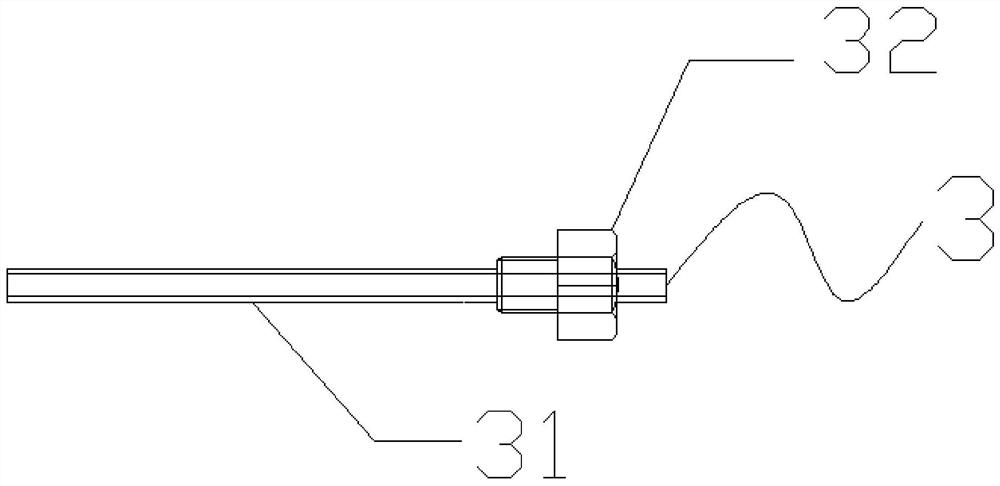

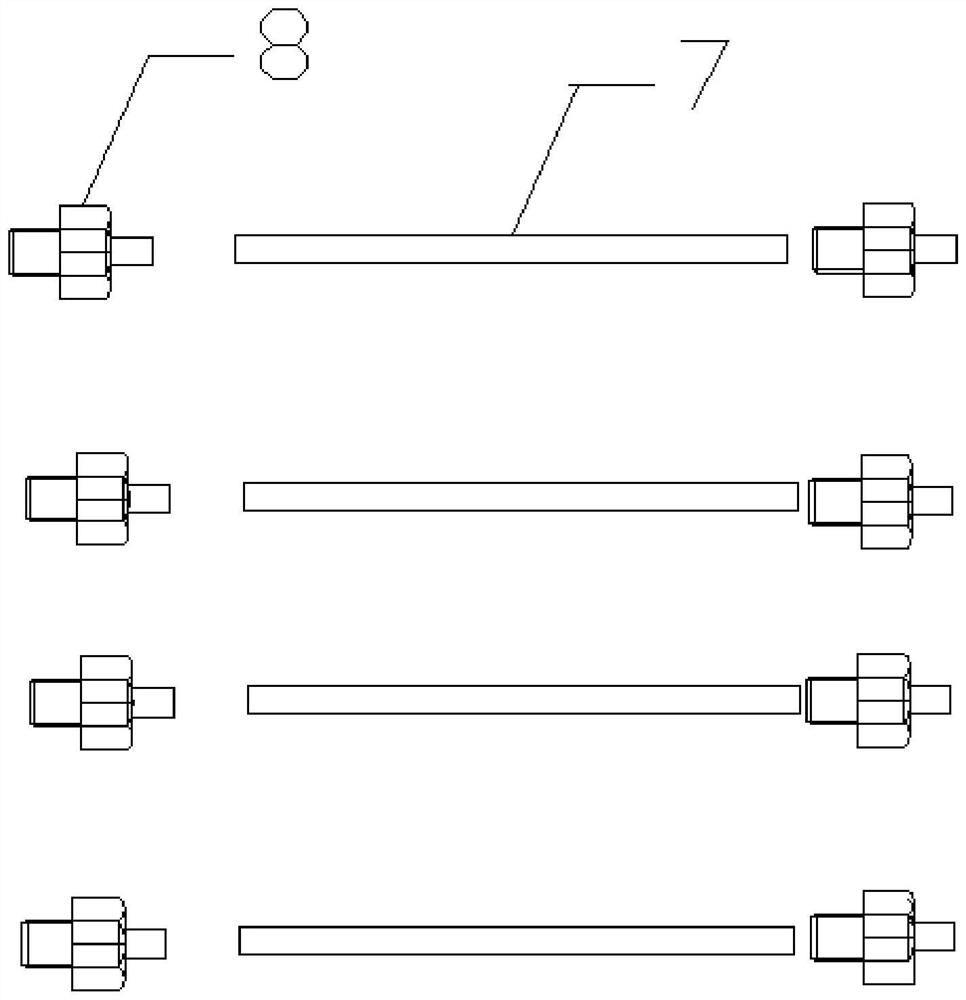

[0039] This embodiment provides a high-efficiency coal slime dissolved gas dehydration process. According to the high-efficiency coal slime dissolved gas dehydration process according to the specific embodiment of the present invention, the process includes: sequentially classifying and sorting the coal slime water, concentrating and precipitating, and pressing and filtering Dehydration, finally forming coal slime; before entering the filter press dehydration, increase the dissolved gas process, the gas dissolved process is: the pressurized gas is mixed into the slime water through the gas device, and then enters the mixing pump, and the impeller rotates at a high speed, and the gas and The coal slime water is broken up, and the formed micro-bubbles fully collide with the coal particles, so that the coal slime water is mineralized by air bubbles, and a gas-dissolved coal slime water with a three-phase mixed system of solid, liquid and gas is formed.

Embodiment 2

[0041]This embodiment provides a high-efficiency coal slime dissolved gas dehydration process. According to the high-efficiency coal slime dissolved gas dehydration process according to the specific embodiment of the present invention, the process includes: sequentially classifying and sorting the coal slime water, concentrating and precipitating, and pressing and filtering Dehydration, finally forming coal slime; before entering the filter press dehydration, increase the dissolved gas process, the gas dissolved process is: the pressurized gas is mixed into the slime water through the gas device, and then enters the mixing pump, and the impeller rotates at a high speed, and the gas and The coal slime water is broken up, and the formed micro-bubbles fully collide with the coal particles, so that the coal slime water is mineralized by air bubbles, and a gas-dissolved coal slime water with a three-phase mixed system of solid, liquid and gas is formed.

[0042] Further, when the pr...

Embodiment 3

[0046] This embodiment provides a high-efficiency coal slime dissolved gas dehydration process. According to the high-efficiency coal slime dissolved gas dehydration process according to the specific embodiment of the present invention, the process includes: sequentially classifying and sorting the coal slime water, concentrating and precipitating, and pressing and filtering Dehydration, finally forming coal slime; before entering the filter press dehydration, increase the dissolved gas process, the gas dissolved process is: the pressurized gas is mixed into the slime water through the gas device, and then enters the mixing pump, and the impeller rotates at a high speed, and the gas and The coal slime water is broken up, and the formed micro-bubbles fully collide with the coal particles, so that the coal slime water is mineralized by air bubbles, and a gas-dissolved coal slime water with a three-phase mixed system of solid, liquid and gas is formed.

[0047] Further, when the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com