Advanced oxidation synchronization/coupling flocculation conditioning method for deep dehydration of sludge

A technology of deep dehydration and advanced oxidation, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve problems such as limited engineering application, save transportation costs, large output, and improve pollution. The effect of mud press filter dewatering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The advanced anaerobic digestion sludge (autumn) to be conditioned is taken from a sewage plant in a certain city. The moisture content of the sludge is 97.2%, the pH value is 6.9, the VSS / TSS value is 0.71, the Zeta potential is -15.6mV, and the SCOD value is 117mg / L at a temperature of 25°C.

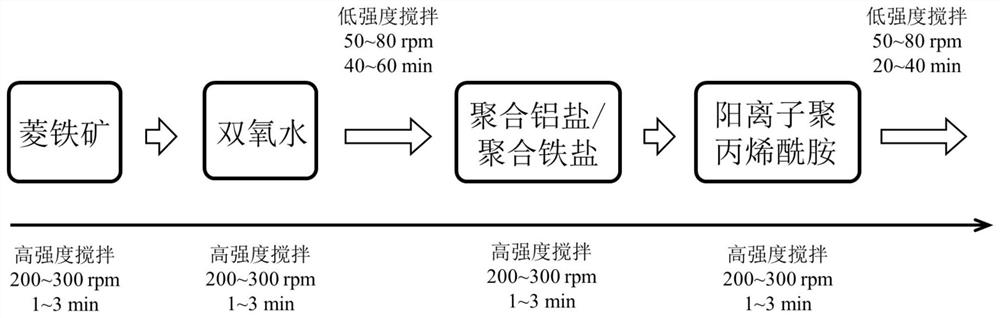

[0035] Conditioning method 1: The specific implementation steps of the conditioning method based on advanced oxidation synchronous / coupling flocculation are as follows:

[0036] 1) After taking 200mL of the sludge to be conditioned in the beaker, stir at 200rpm for 1min to mix the sludge evenly;

[0037] 2) Add 2 g of siderite powder with a particle size of 150 μm to the sludge liquid, and stir at 200 rpm for 2 minutes;

[0038] 3) Add 1mL of hydrogen peroxide (30% effective volume concentration) to the sludge mixture 2 minutes after the conditioning starts, stir at 200rpm for 2min at high intensity, then stir at 50rpm for 56min at low intensity, and confirm the cell wall by dete...

Embodiment 2

[0056] The advanced anaerobic digestion sludge (winter) to be conditioned is taken from a sewage plant in a city. The moisture content of the sludge is 96.5%, the pH value is 6.6, the VSS / TSS value is 0.67, the Zeta potential is -13.8mV, and the SCOD value is 108mg / L at a temperature of 25°C.

[0057] Conditioning method 1: The specific implementation steps of the conditioning method based on advanced oxidation synchronous / coupling flocculation are as follows:

[0058] 1) After taking 200mL of the sludge to be conditioned in the beaker, stir at 200rpm for 1min to mix the sludge evenly;

[0059] 2) Add 2 g of siderite powder with a particle size of 150 μm to the sludge liquid, and stir at 200 rpm for 2 minutes;

[0060] 3) Add 1mL of hydrogen peroxide (effective concentration: 30%) to the sludge mixture 2 minutes after conditioning, stir at 200rpm for 2min at high intensity, then stir at 50rpm for 56min at low intensity, and confirm the cell wall rupture rate by detecting ATP ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com