Energy-saving and environment-friendly animal waste recycling, drying and combustion treatment equipment

A technology for animal excrement and treatment equipment, which is used in dewatering/drying/concentrating sludge treatment, pyrolysis treatment sludge, animal husbandry wastewater treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

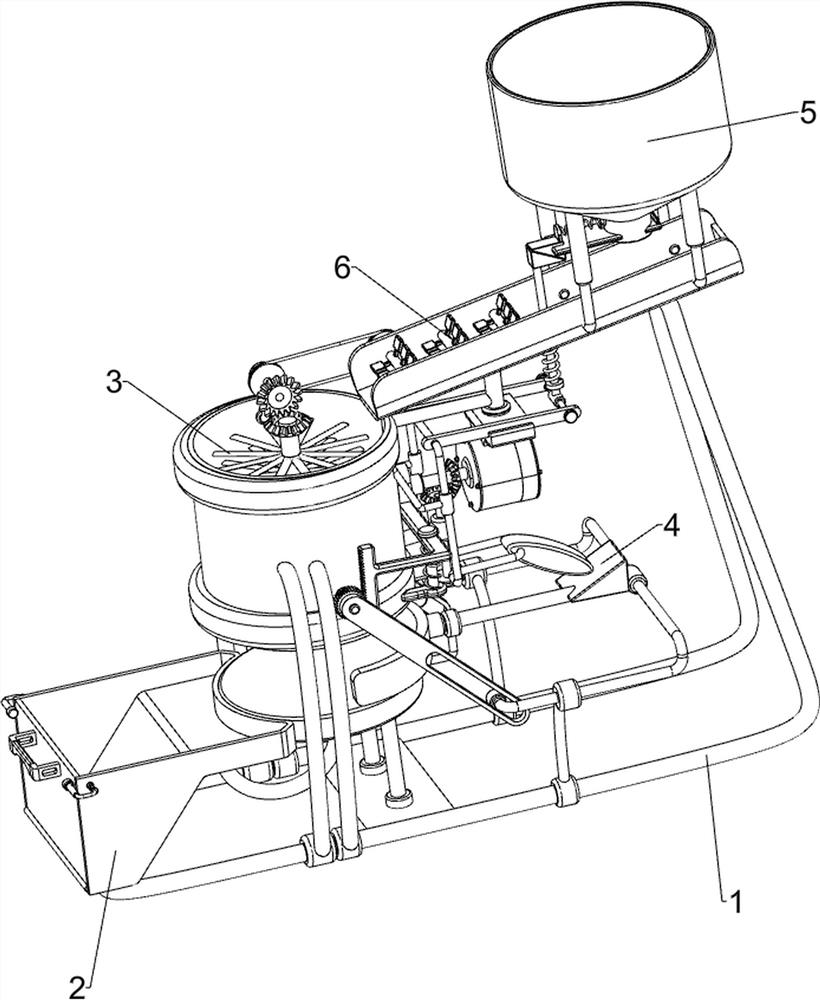

[0047] A kind of energy-saving and environment-friendly animal manure recovery dry burning treatment equipment, such as Figure 1 to Figure 3 As shown, a combustion mechanism 1 and a collection mechanism 2 are included, and the combustion mechanism 1 is connected with the collection mechanism 2 .

[0048] The combustion mechanism 1 includes a first fixed frame 11, a first support rod 12, a combustion barrel 13, a second support rod 14 and a placement plate 15, and the left part of the first fixed frame 11 is symmetrically provided with a first support rod 12. A combustion barrel 13 is connected between the tops of the rods 12, and there are 2 discharge holes on the left side of the bottom of the combustion barrel 13. The top of the first fixed frame 11 is symmetrically provided with a second support rod 14, and the top of the second support rod 14 is connected with a Place plate 15, and place plate 15 is positioned at combustion bucket 13 below.

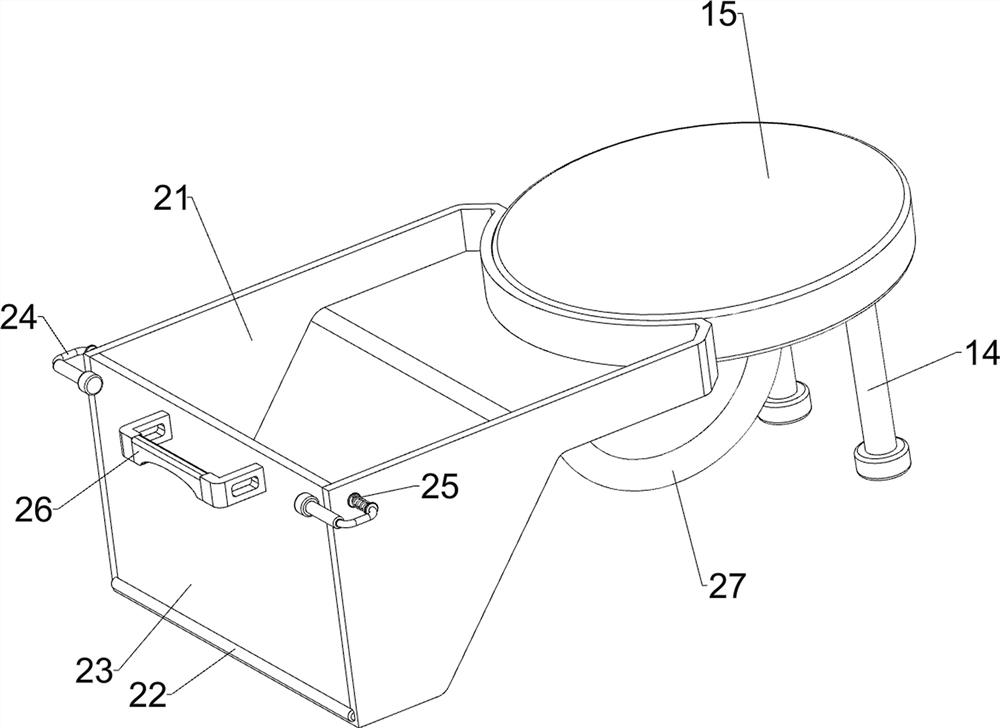

[0049] The collection mechan...

Embodiment 2

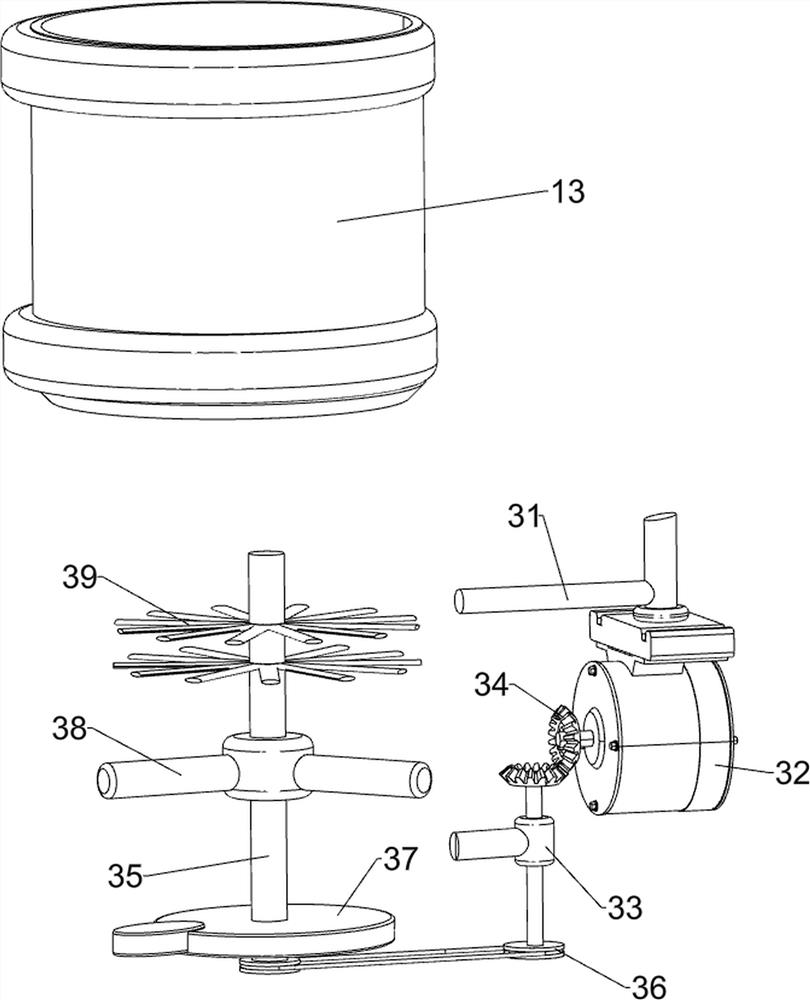

[0052] On the basis of Example 1, such as Figure 4 and Figure 5As shown, a rotating mechanism 3 is also included, and the rotating mechanism 3 includes a second fixed rod 31, a motor 32, a third fixed rod 33, a first bevel gear set 34, a second rotating shaft 35, a first transmission assembly 36, a first Cam 37, the second fixed frame 38 and rotating piece 39, the right side of the upper part of the combustion barrel 13 is connected with the second fixed rod 31, the second fixed rod 31 is provided with a motor 32, and the right side of the lower part of the combustion barrel 13 is connected with the third fixed rod 33, the right part of the third fixed rod 33 is connected with the first bevel tooth group 34 between the short rod and the output shaft of the motor 32, the inner wall of the combustion barrel 13 is connected with the second fixed frame 38, and the second fixed frame 38 is connected in a rotating manner There is a second rotating shaft 35, a first transmission a...

Embodiment 3

[0056] On the basis of Example 2, such as Figure 6 and Figure 7 Shown, also include unloading mechanism 5, unloading mechanism 5 includes the seventh fixed rod 51, push frame 52, the 3rd spring 53, slide plate 54, unloading barrel 55, baffle plate 56 and the 4th spring 57, combustion The seventh fixed rod 51 is symmetrically arranged on the right side of the upper part of the bucket 13, and a push frame 52 is slidably connected between the seventh fixed rods 51. The push frame 52 cooperates with the push rod 49, and a slide plate 54 is connected to the right side of the top of the first fixed frame 11. , the right part of the slide plate 54 is connected with the lower material barrel 55, the lower part of the lower material barrel 55 is slidingly connected with the baffle plate 56, the fourth spring 57 is connected between the top of the baffle plate 56 and the lower material barrel 55, and the middle part of the baffle plate 56 is slidingly connected. There is a wedge, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com