High-toughness glass fiber reinforced polyphenylene sulfide composite material and preparation method thereof

A polyphenylene sulfide and composite material technology, applied in the field of PPS modified plastics, can solve the problems of poor toughening effect, good crystallinity, poor toughening effect of PEEK, etc., achieve good toughening effect, improve adhesion The effect of improving force and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

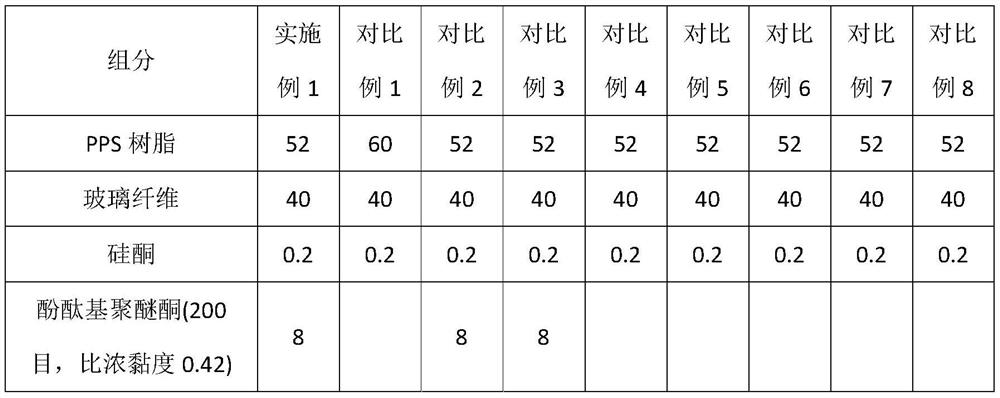

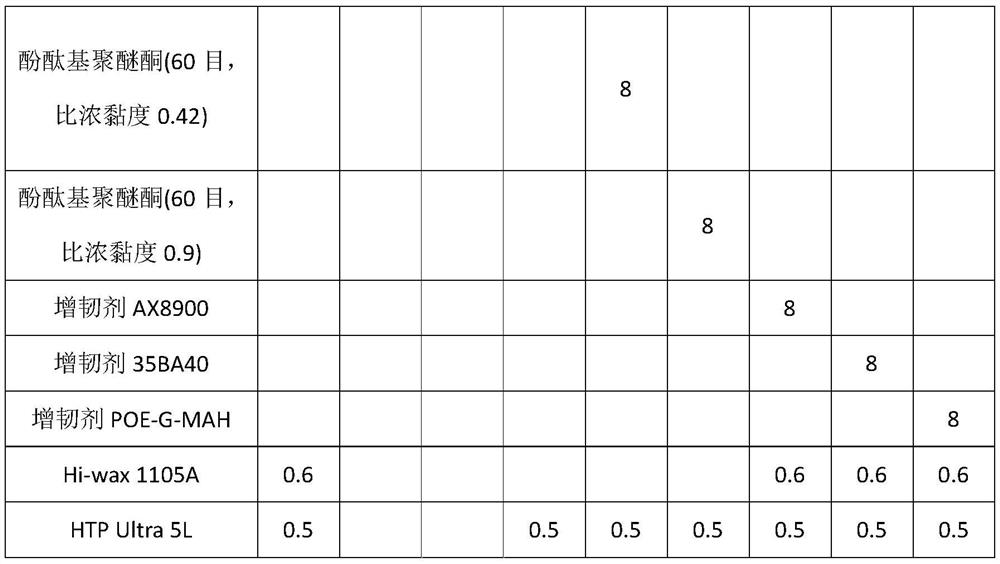

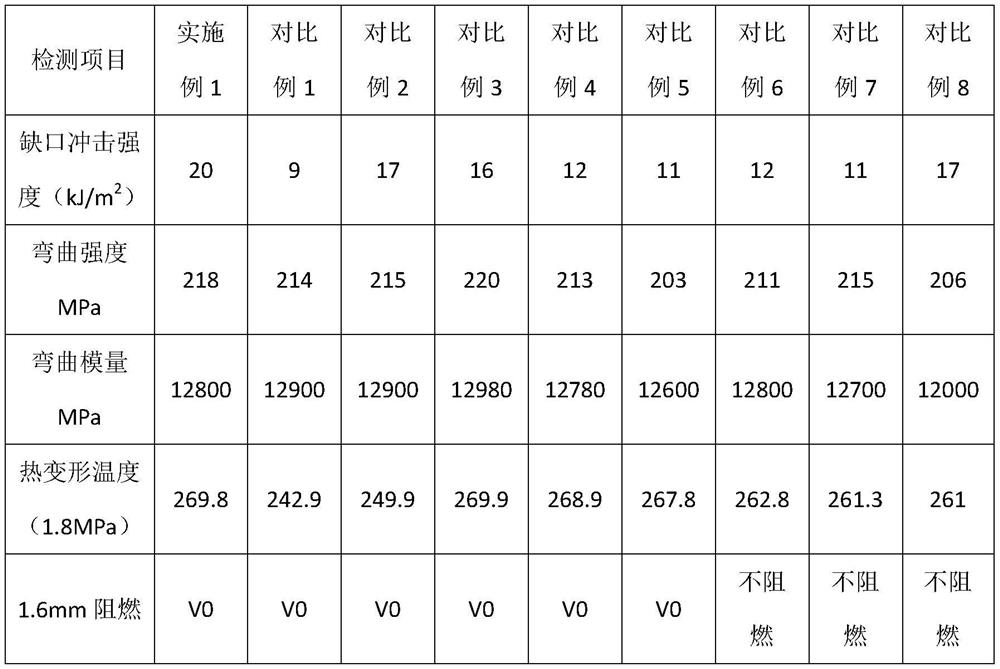

[0031] The preparation method, effect and application of the present invention will be further described below in conjunction with the examples. The examples are only representative of typical schemes, and the present invention is not limited to the methods of the examples.

[0032] Raw materials used in examples and comparative examples: PPS resin, Xinhecheng 1350C; glass fiber, Owens Corning GF910A-10P; silicone, Dow Corning MB50-001; Zhejiang Parco NM series phenolphthalein polyether ketone; dispersant , Japan Mitsui Chemicals polyethylene wax Hi-wax 1105A; nucleating agent is talc HTP Ultra5L.

[0033] A high-toughness glass fiber reinforced polyphenylene sulfide composite material, comprising the following components in parts by weight:

[0034] 40-70 parts of polyphenylene sulfide resin, 30-50 parts of glass fiber, 3-10 parts of phenolphthalein-based polyether ketone, 0.3-0.6 parts of nucleating agent, 0.5-1 part of dispersant, and 0.1-0.3 parts of high-temperature lubri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament diameter | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com