Novel pipeline connectivity inspection method

A connectivity inspection and pipeline technology, which is applied in the field of pipeline connectivity inspection, can solve problems such as limited use environment, high personnel safety hazards, and low operating efficiency, and achieve the effects of solving environmental requirements, reducing operating costs, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention, and the technical solution of the present invention will be further described in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

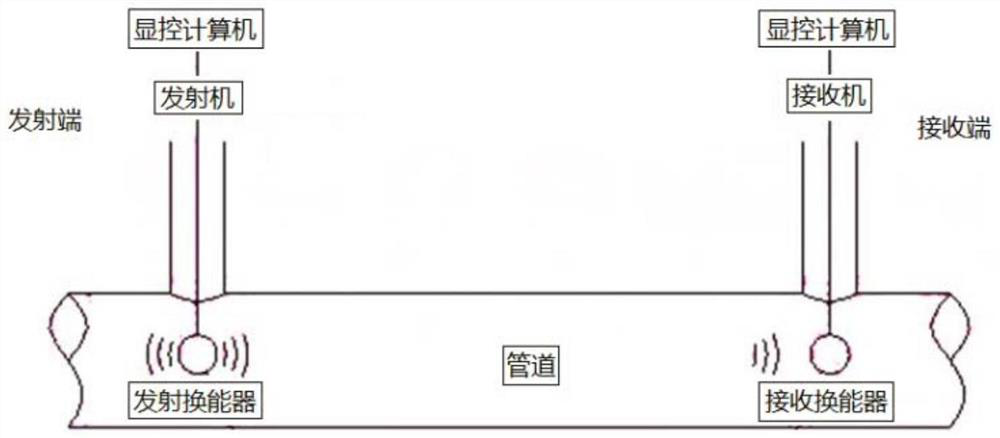

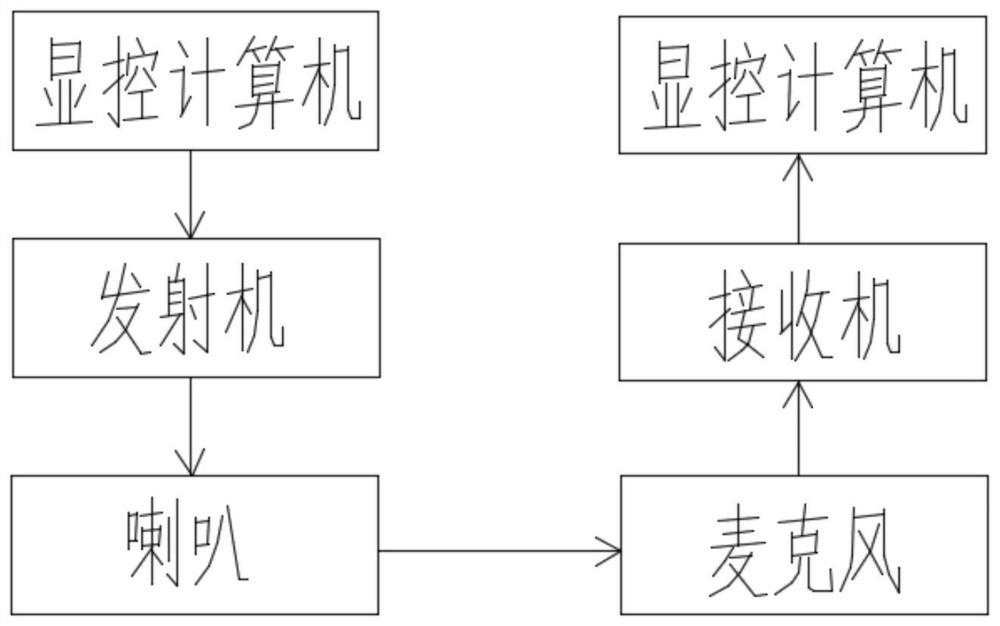

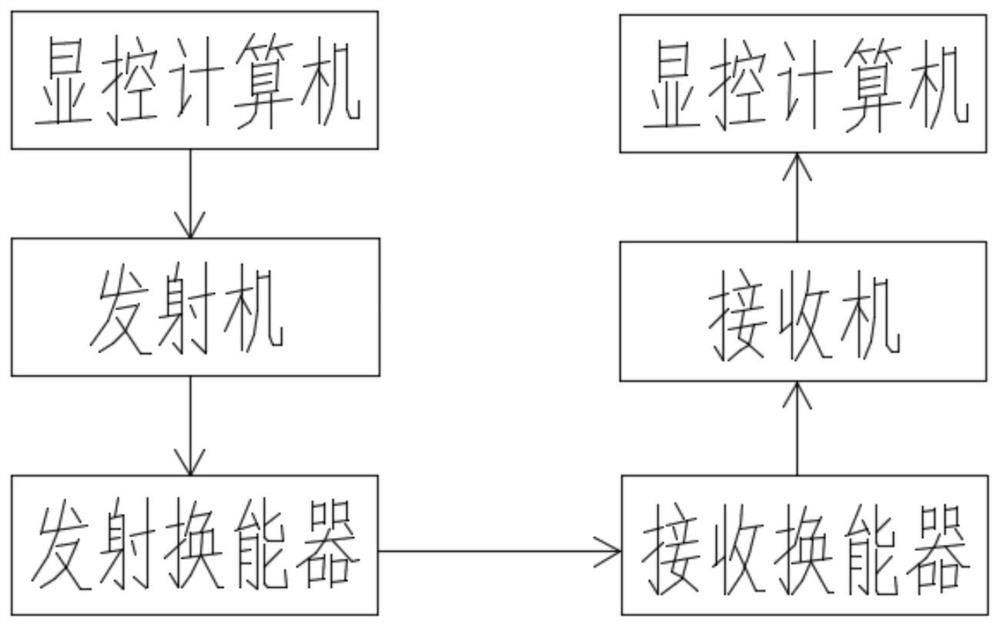

[0031] Such as Figures 1 to 3 As shown, for the wet sub-system, the transmitting transducer and the display and control computer are respectively connected to the transmitter through electrical connectors, the display and control computer issues an instruction to emit sound waves, and the transmitter receives the emission instruction and converts the emission instruction into an electrical signal. The transmitting transducer converts the received electrical signal into an acoustic signal and emits it, propagating in the pipeline;

[0032] At the other end of the pipeline system, the receiving transducer and the display and control computer are respectively connected to the receiver through electrical connectors. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com