Water-cooled wall horizontal type cement cooling device with built-in spring

A cooling device and built-in spring technology, which is applied in household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of low operation efficiency, easy blockage of nozzles, and large equipment volume, so as to enhance the heat exchange effect and increase the Heat exchange area and the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

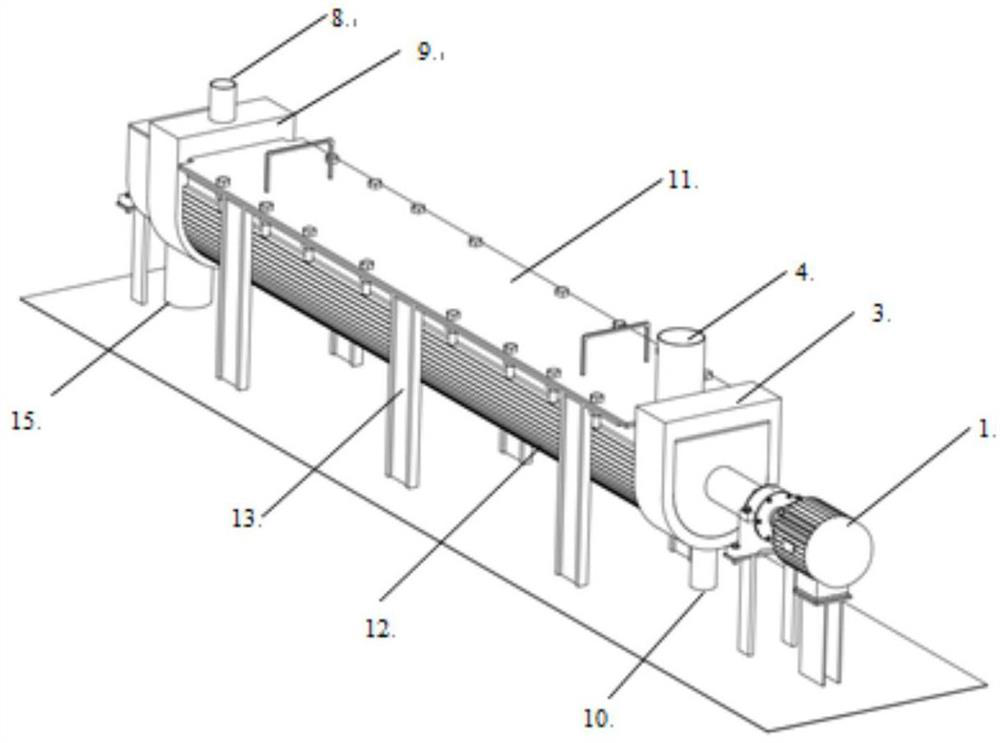

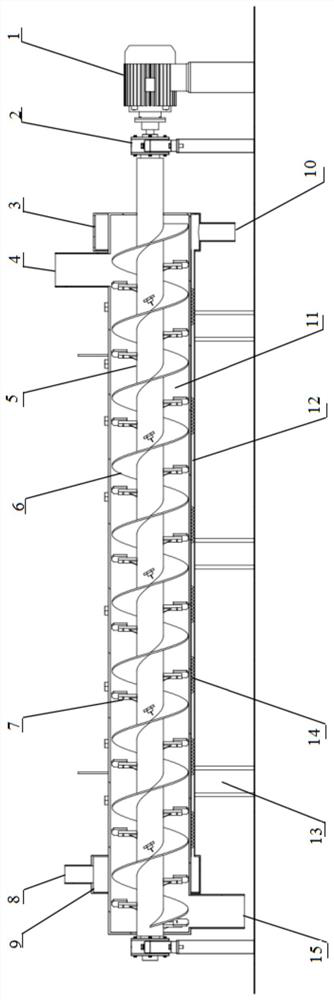

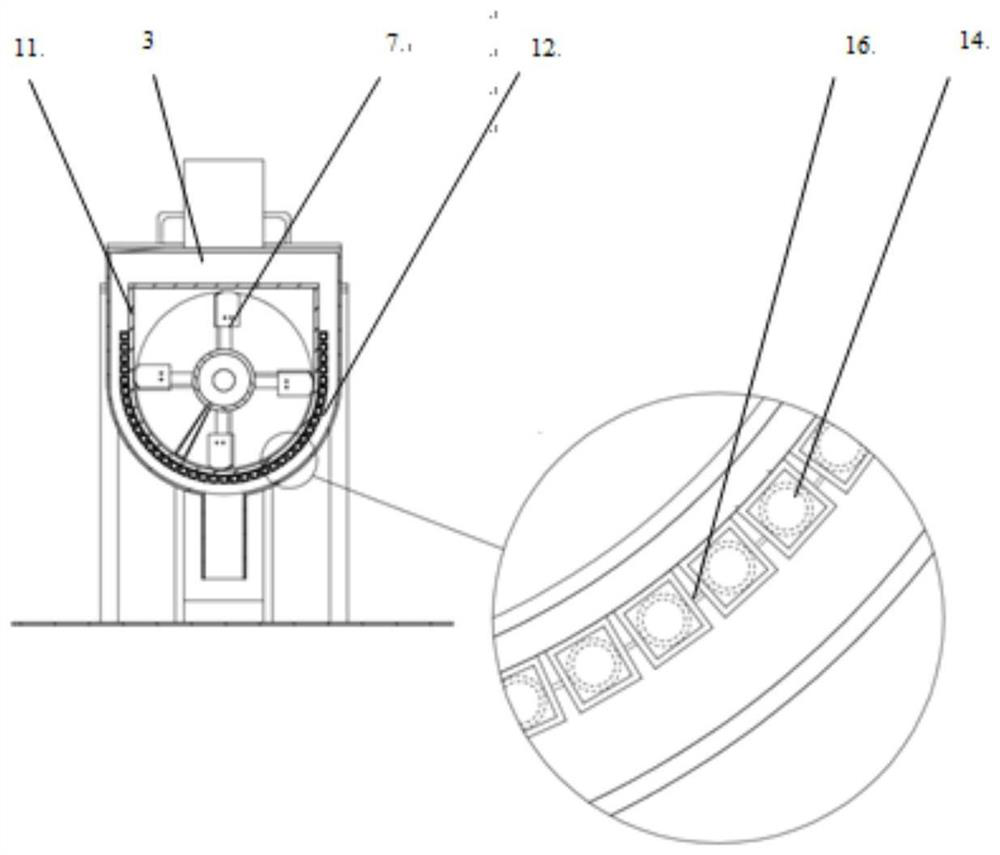

[0027] Embodiment: a water wall horizontal cement cooling device with built-in spring, such as Figure 1-Figure 3 As shown, it includes a support 13 for installation and a cylinder 11 installed on the support;

[0028] The inside of the cylinder is provided with a hollow shaft 5, and one end of the hollow shaft is connected with the reducer 2 and the motor 1 to drive the hollow shaft to rotate;

[0029] The outer periphery of the hollow shaft is welded with spiral blades 6 and lifting blades 7;

[0030] The outer peripheral surface of the lower part of the cylinder is provided with a water wall for cooling the material in the cylinder.

[0031] The two ends of the cylinder are provided with a feed port 4 and a discharge port 15 for the material, and a cooling water inlet 8 and a water separation bin 9 are arranged at the discharge port, and the cooling water inlet and the water separation bin Communication; a water collection bin 3 and a hot water outlet 10 are arranged at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com