Penetration blasting warhead containing active fragment inclusions in titanium alloy matrix and its preparation method

A titanium alloy and warhead technology is applied in the field of fragmentation warheads to achieve the effects of improving combat capability, improving ignition and detonation functions, and improving damage efficiency and utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation examples.

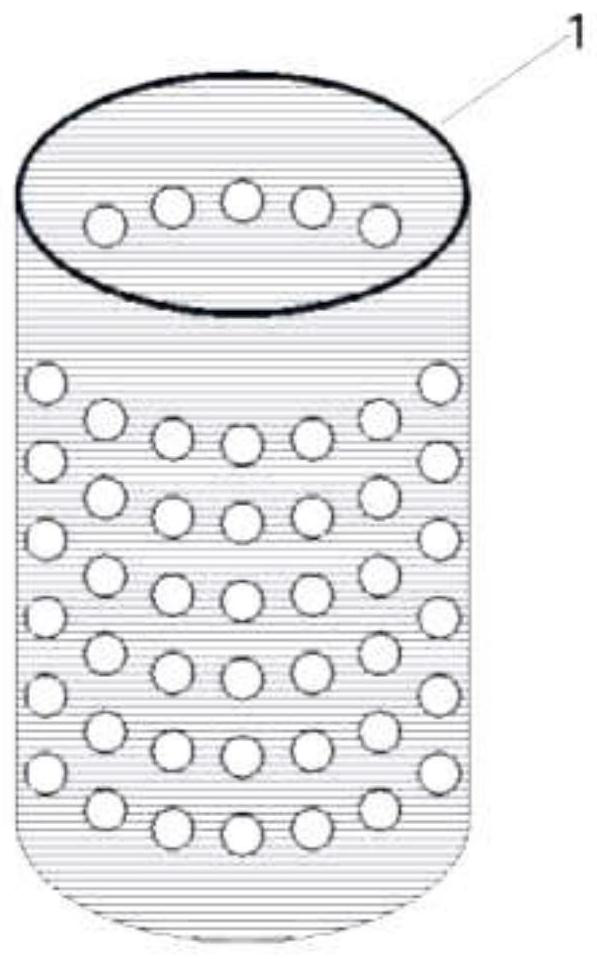

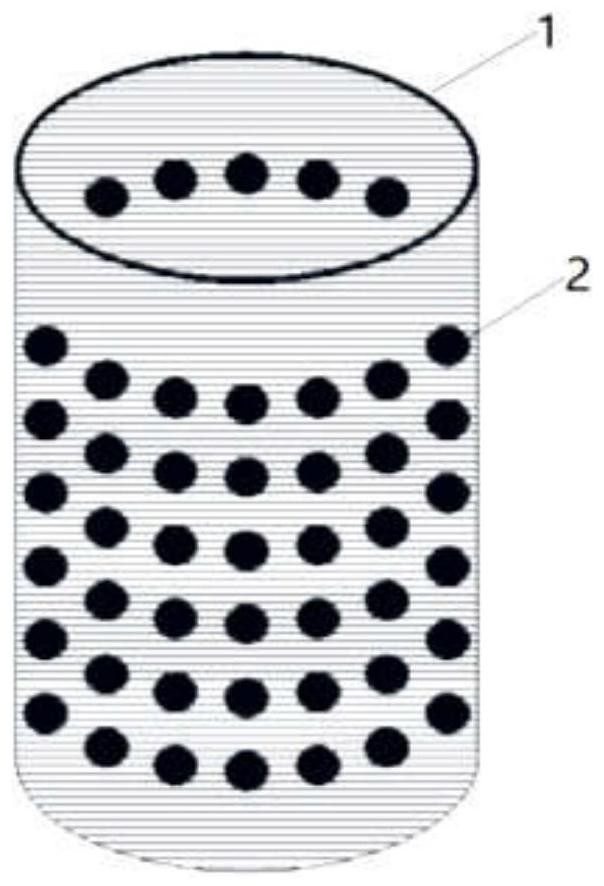

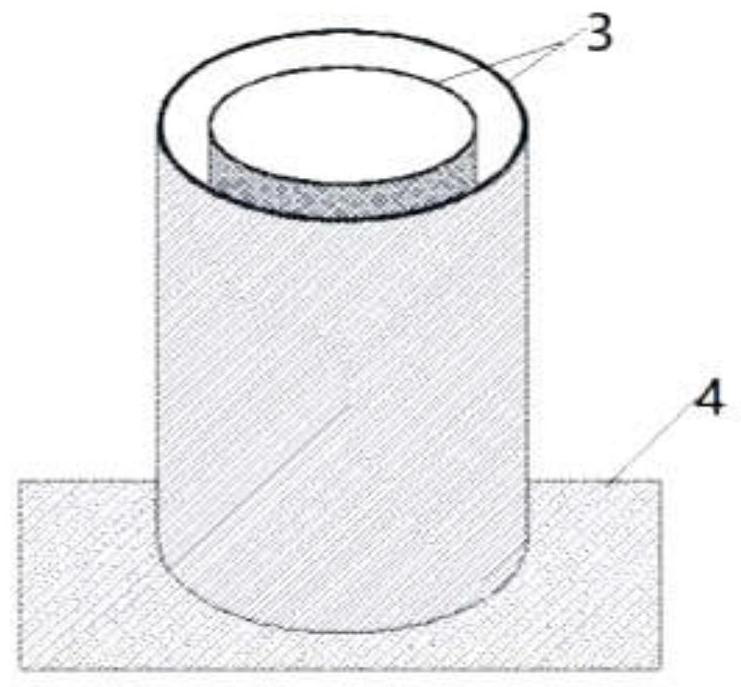

[0036] combine Image 6 The schematic diagram of the overall structure of the warhead is shown. A truncated oval warhead 7 with a certain coefficient of bullet-to-diameter ratio is processed. A section protrudes from the tail of the truncated oval warhead. An external thread is provided to cooperate with the internal thread of the shell; 3D printing technology is used to design a thin-walled round titanium alloy warhead. Cylinder skeleton 1, stick high-density active fragments 2 to the array empty slots of titanium alloy thin-walled cylindrical skeleton 1, after the active fragments 2 are fixed, place them in the mold composed of mold cylinder 3 and mold base 4, add Titanium alloy metal powder 5, wherein the surface roughness of the active fragment 2 needs to be increased to increase the bonding area with the matrix titanium alloy, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com