Rock strength prediction system and method based on lithofacies characteristic analysis

A technology for strength prediction and feature analysis, applied in the field of rock mechanical property determination, which can solve the problems of low accuracy of calculation results, time-consuming and laborious, and damage to the target rock mass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

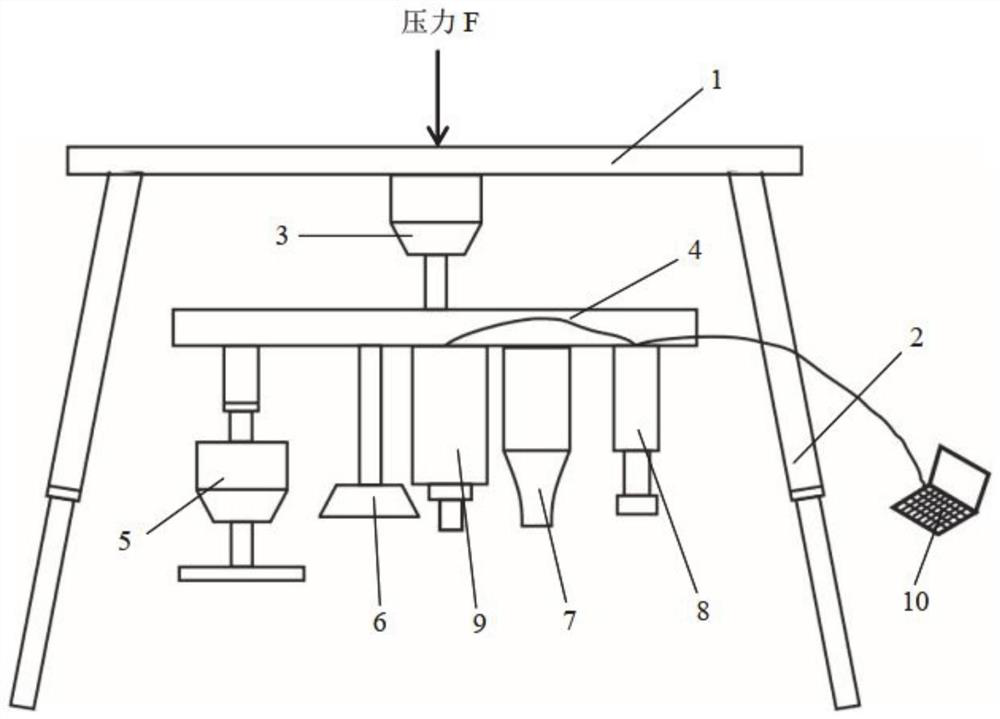

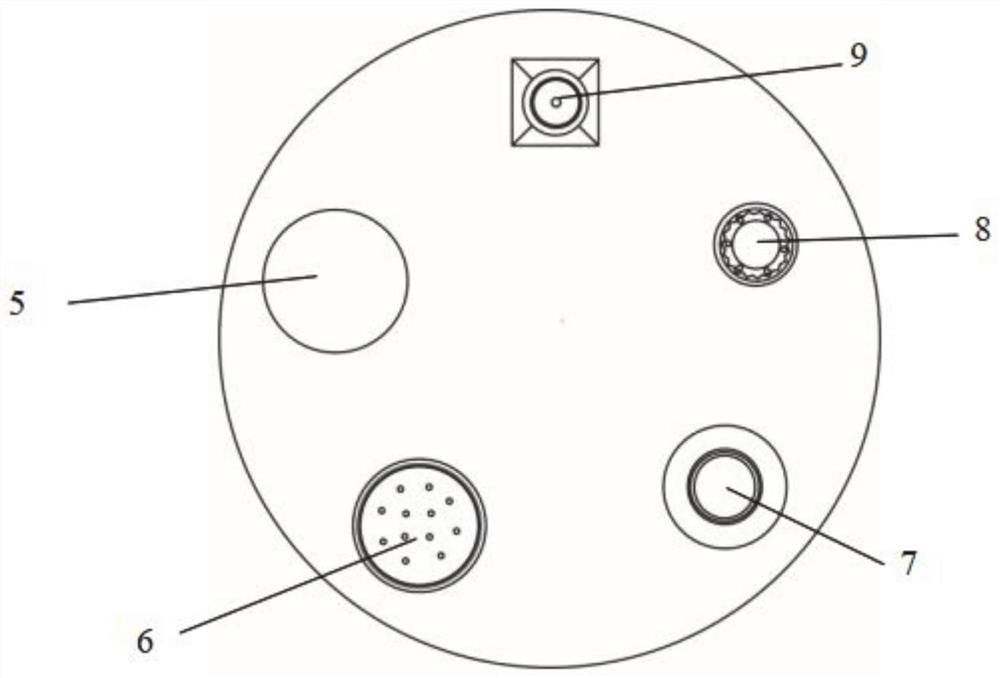

[0041] This embodiment provides a rock strength prediction system based on petrographic feature analysis, such as figure 1 As shown, it includes a supporting mechanism, a rotating mechanism, a grinding mechanism 5, a cleaning mechanism 6, a drying mechanism 7, a structure identification mechanism 8, a mineral analysis mechanism 9, a strength prediction system 10 and a control system. The grinding mechanism 5, the cleaning mechanism 6. The drying mechanism 7, the structure identification mechanism 8, and the mineral analysis mechanism 9 are all fixed to the rotation mechanism, and the rotation mechanism is fixed to the support mechanism; the structure identification mechanism 8, the mineral analysis mechanism 9 are connected to the strength prediction system 10.

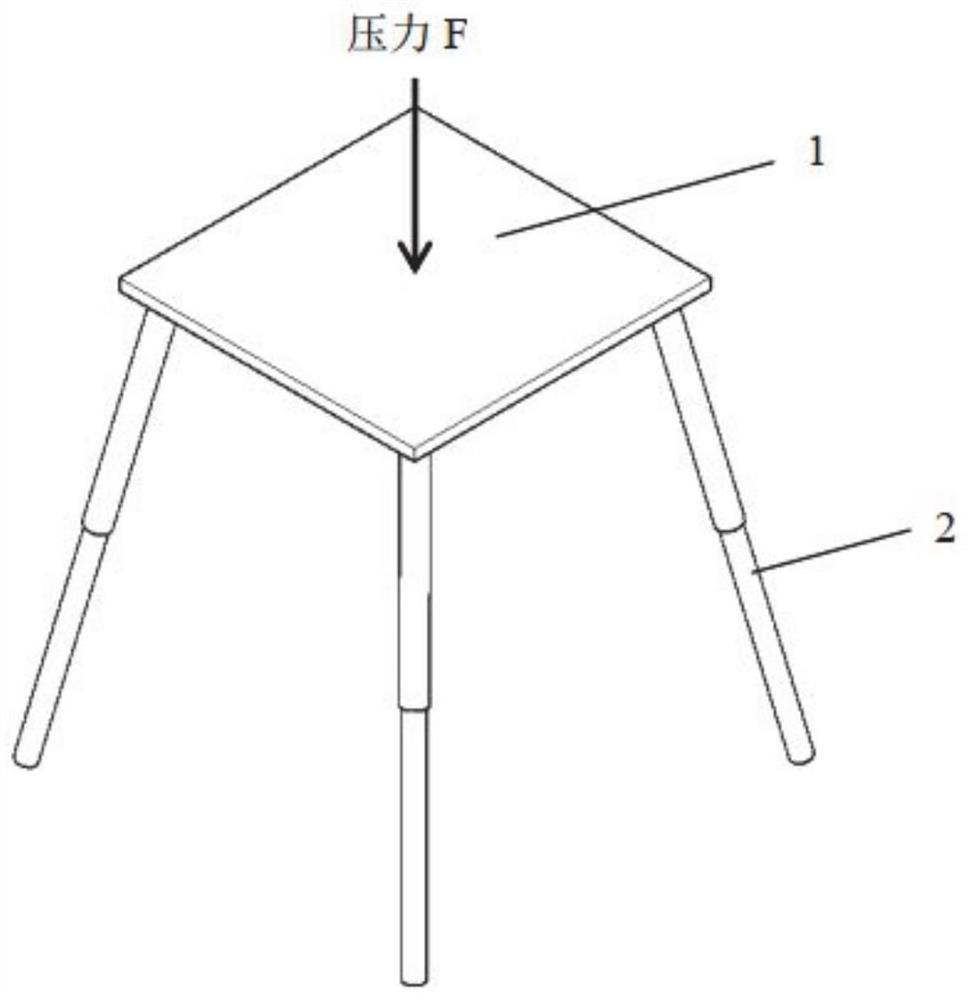

[0042] Further, such as figure 2As shown, the support mechanism includes a ceiling 1 and a plurality of telescopic supports 2, and the plurality of telescopic supports 2 are evenly spaced and connected under the ceil...

Embodiment 2

[0061] This embodiment provides a rock strength prediction method based on petrographic feature analysis, using the prediction system described in Embodiment 1, such as Image 6 shown, including the following steps:

[0062] (1) After selecting the target rock mass to be measured, the prediction system is placed above the target rock mass to be measured, and the telescopic support 2 is adjusted so that the ceiling 1 is parallel to the surface of the rock mass to be measured, and at the same time it is installed on the turntable 4 Each mechanism is as close as possible to the rock mass to be tested; and a pressure F perpendicular to the target rock mass is applied above the ceiling 1 .

[0063] (2) Firstly, the hydraulic rod 5-1 in the grinding mechanism 5 is stretched out to ensure that the fine grinding wheel 5-3 sticks to the target rock mass to be measured; then start the second servo motor 5-2 to make the fine grinding wheel 5-3 fast Turn and grind the target rock mass. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com