Method for intelligently detecting defective glass image, electronic equipment and storage medium

An intelligent detection and image technology, applied in image enhancement, image analysis, image data processing, etc., can solve problems such as unfavorable data backtracking, inconvenient defect data storage, cutting linear fluctuations, etc., to reduce the risk of entering the market and improve products Detection efficiency, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( Embodiment 1

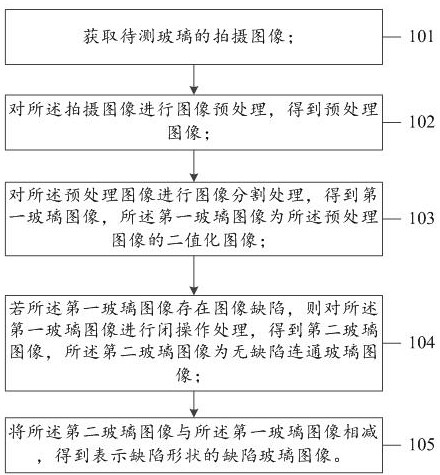

[0056] see figure 1 , an embodiment (Embodiment 1) of the method for intelligently detecting defective glass images in the embodiment of the present application includes:

[0057] 101. Obtain a photographed image of the glass to be tested;

[0058] In this embodiment, in the captured images of the glass to be tested, the glass to be tested is the glass that has been cut and separated, and each glass has a corresponding product serial number; in order to improve the product quality of the glass that leaves the factory, it is necessary Detect the glass on the cut surface, and record the information of the cut surface; for example, identify the product serial number of the glass product through a code reader, and use an image sensor to obtain an edge image of the cut glass (that is, a captured image of the glass to be tested); Wherein, the glass to be tested is a regular rectangular panel with four cutting surfaces, and each cutting surface needs to be detected, and each cutting...

Embodiment ( Embodiment 2

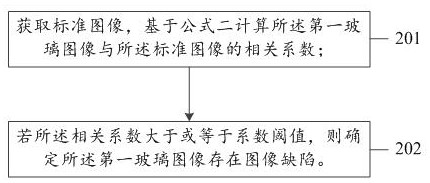

[0084] see figure 2 , the second embodiment (embodiment 2) of the method for intelligently detecting defective glass images in the embodiment of the present application includes:

[0085] 201. Acquire a standard image, and calculate a correlation coefficient between the first glass image and the standard image based on Formula 1;

[0086] In this embodiment, the standard image refers to a non-defective glass image, which is determined according to the customer's quality requirements for the image; defect image, it is necessary to calculate the correlation coefficient between the standard image and the first glass image (that is, the binarized image), and then determine whether it is a defect image according to the size of the correlation coefficient; in practical applications, the correlation coefficient is based on formula 1 Calculation, the following is the expression of Formula 1:

[0087]

[0088] Wherein, NCC represents the correlation coefficient between the standa...

Embodiment ( Embodiment 3

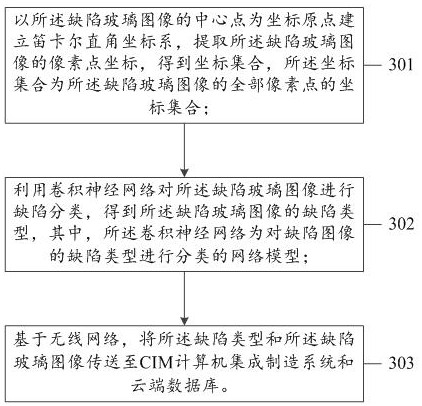

[0093] see image 3 , the third embodiment (Embodiment 3) of the method for intelligently detecting defective glass images in the embodiment of the present application includes:

[0094] 301. Establish a Cartesian coordinate system with the center point of the defective glass image as the coordinate origin, extract the pixel point coordinates of the defective glass image, and obtain a coordinate set, and the coordinate set is all the pixel points of the defective glass image set of coordinates;

[0095] In this embodiment, in order to conveniently determine the defect position of the defect image, it is necessary to locate the defect image, and the defect image positioning is used to quickly find the defect position of the glass product, which is convenient for realizing physical repair and finding and determining the edge of the glass cutting edge. Causes of defects, reduce the product error rate of cut glass; the image acquired by the sensor is a rectangular image, there ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com