Ultra-violet curing optically variable nail polish and preparation method thereof

A technology of ultraviolet light and nail polish, which is applied in the direction of cosmetic preparations, cosmetics, manicure, etc., and can solve the problems of weak visual impact and narrow range of nail polish discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] Preparation of UV curable resin A:

[0080] UV curable resin A-1:

[0081] Add 320g of polytetrahydrofuran ether diol into a four-necked flask equipped with mechanical stirring, a thermometer and a vacuum device, dehydrate at 112°C and a vacuum of 0.88MPa for 1.5h; cool down the dehydrated polytetrahydrofuran ether diol to 78°C, add 40g of isophorone diisocyanate and 0.5g of bismuth isooctanoate into a four-necked flask, control the temperature at 78°C, and after 2 hours of reaction, cool down to 72°C, add 23g of capping agent hydroxyethyl acrylate to In the four-necked flask, the temperature was controlled at 72°C, and the reaction was stopped when the NCO value dropped below 0.02%, to obtain UV curable resin A-1 with a functionality of 2.

[0082] UV curable resin A-2:

[0083]Add 270g of polypropylene glycol polyether diol into a four-necked flask equipped with mechanical stirring, a thermometer and a vacuum device, and dehydrate for 1 hour at 115°C and a vacuum of...

Embodiment 1-6

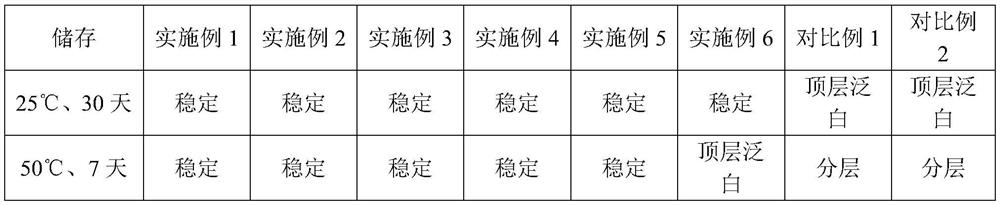

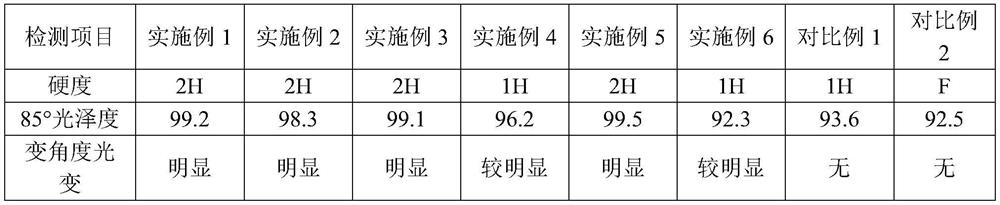

[0093] The preparation of photocurable light-changing nail polish, formula is as shown in table 1 (weight part), and its preparation method comprises the following steps:

[0094] (1) Add the photoinitiator and polymerization inhibitor into the diluted monomer according to the ratio of ingredients, stir at 500r / min for 10min, dissolve and mix evenly;

[0095] (2) Under the condition of stirring, add UV curable resin A and UV curable resin B, stir at 1000r / min for 30min until uniformly mixed, continue to add rheology modifier, stir for 30min until uniformly mixed, then add optical variable pigment and Ordinary pigments, stirred for 30 minutes until uniformly mixed, filtered, and discharged to obtain the light-curable light-varying nail polish.

[0096] Table 1:

[0097]

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com