Tail gas treatment device for underground engineering construction machinery

A technology for construction machinery and underground engineering, which can be used in exhaust devices, mechanical equipment, mufflers, etc., and can solve problems such as hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

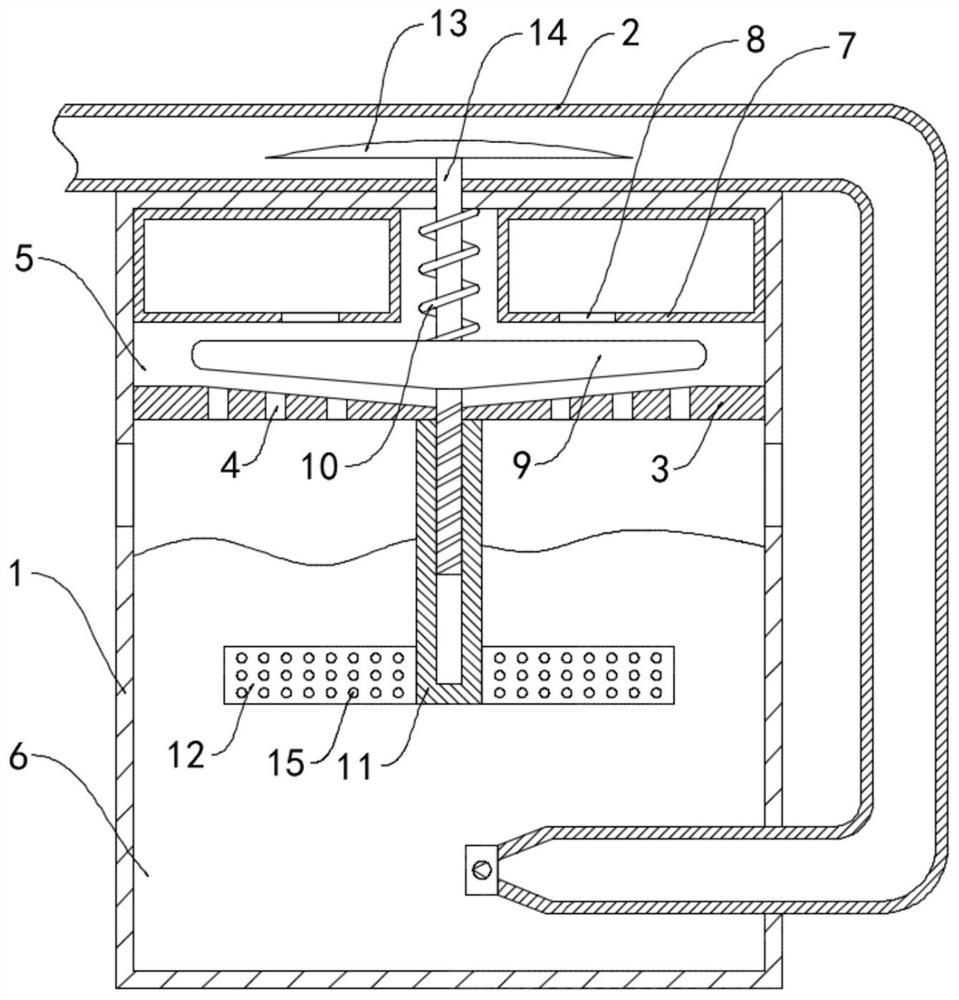

[0024] Such as figure 1 As shown, an exhaust gas treatment device for underground engineering construction machinery includes a housing 1 and an air intake pipe 2 fixedly connected to the housing 1. The air intake pipe 2 communicates with the end of the exhaust gas discharge pipe of the underground engineering construction machinery. A horizontal sieve plate 3 is fixedly connected to the wall, and a plurality of sieve holes 4 are equidistantly arranged in the sieve plate 3 .

[0025] Further, the top surface of the material storage chamber 5 is fixedly connected with an annular material storage box 7, and the annular material storage box 7 is filled with scavenger particles, the scavenger particles are sodium hydroxide solid particles, and the bottom of the annular material storage box 7 is provided with A horizontal grinding plate 9 is provided below the discharge port 8 and the annular material storage box 7 , and the grinding plate 9 is fixedly connected to the top surface ...

Embodiment 2

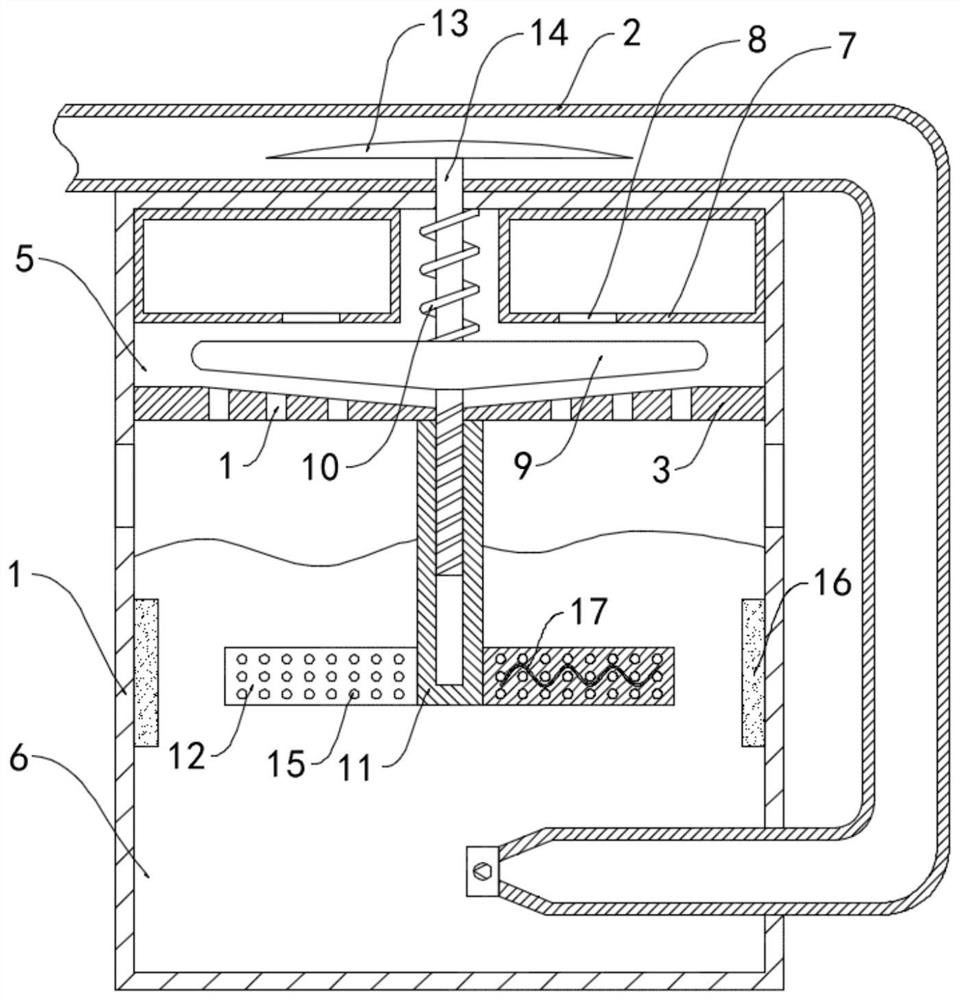

[0033] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that: the inner wall of the clean chamber 6 is fixedly connected with a permanent magnet ring 16, the spoiler 12 is embedded with a helical coil 17, and the two conductive ends of the helical coil 17 They are connected to each other to form a closed loop, and the winding direction of the helical coil 17 is perpendicular to the direction of the magnetic field line of the permanent magnetic ring 16 .

[0034] In this embodiment, when the helical coil 17 rotates synchronously with the spoiler 12, the magnetic induction lines of the permanent magnetic ring 16 are continuously cut to generate an induced current, and the electric energy is converted into heat energy to generate heat, and the alkaline solution is heated to accelerate the process of the alkaline solution. The evaporation rate of the solvent water increases the concentration of the alkaline solution. At the same time, water is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com