Fully-closed automatic pot charging system

A fully enclosed and automatic technology, applied in feeding devices, chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, etc., can solve the problem that the slag valve and the gas outlet valve cannot be locked and operated with each other. Mistakes, poor exhaust gas neutralization and poor handling seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

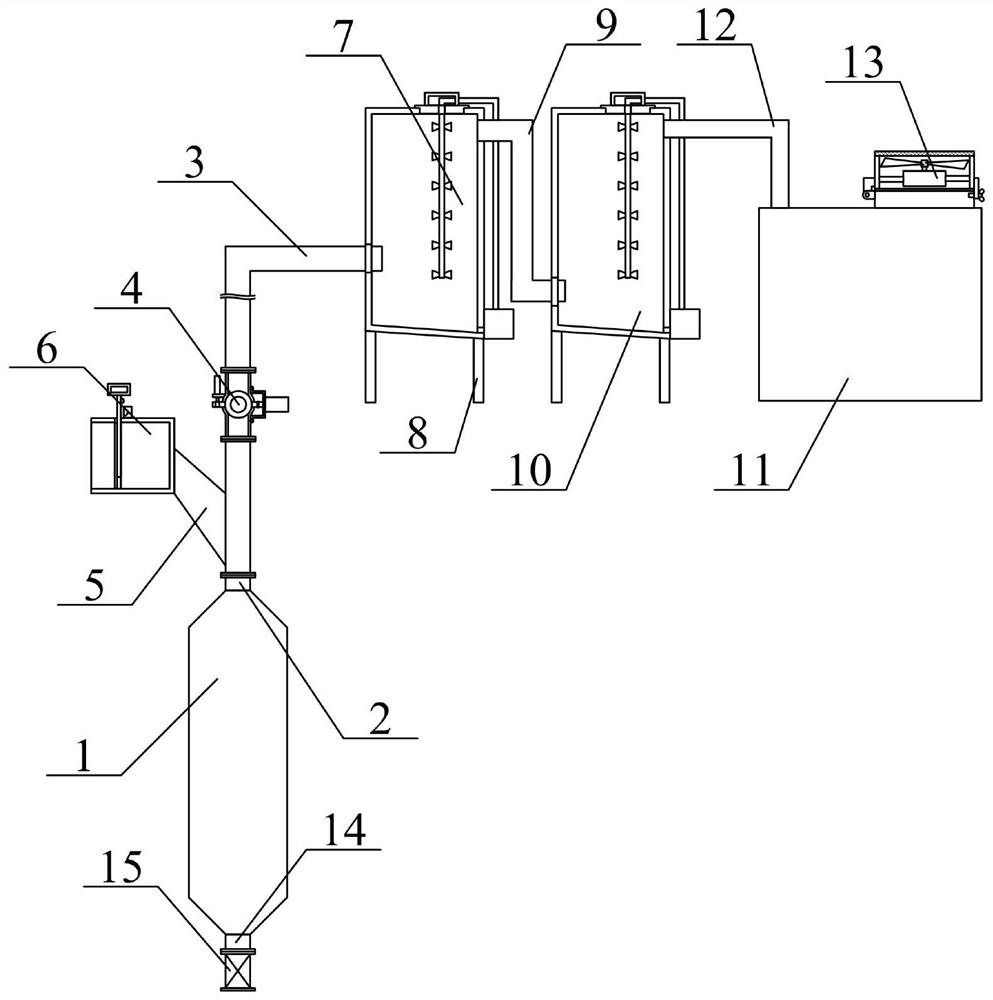

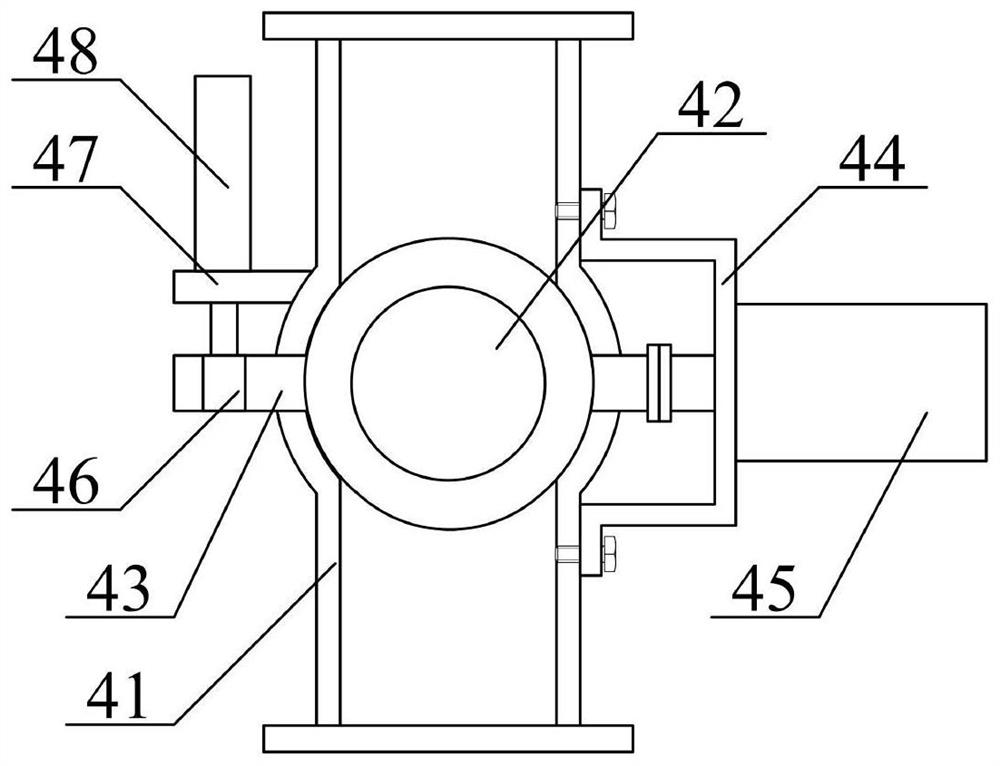

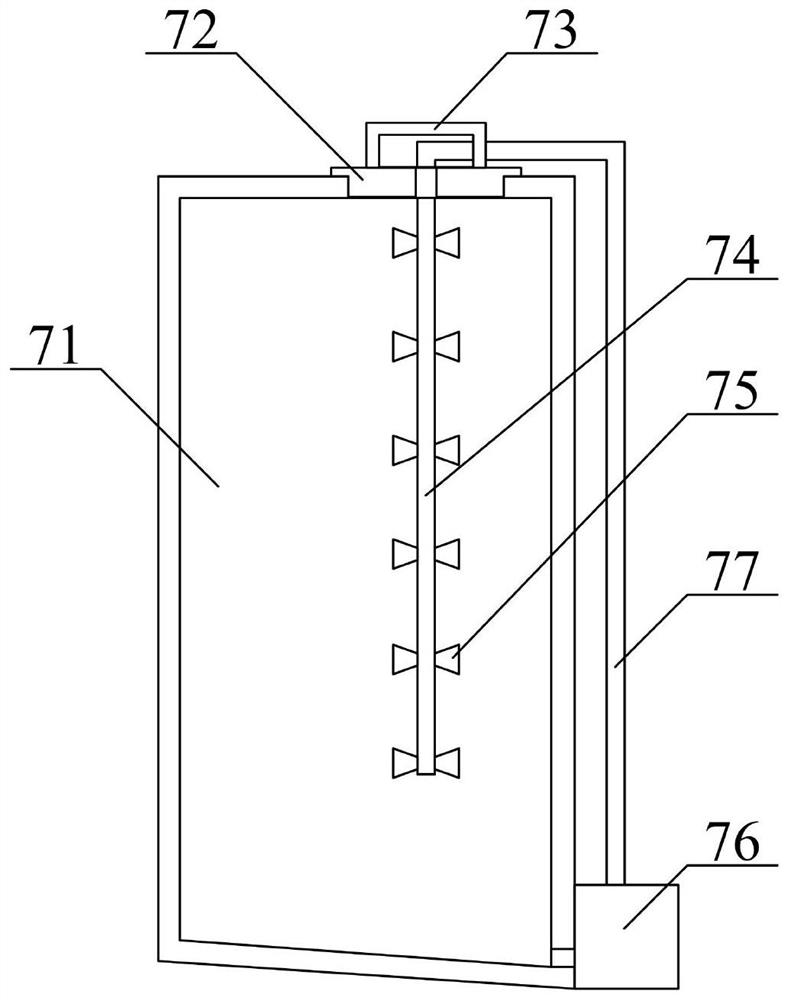

[0035] as attached figure 1 And attached figure 2 As shown, the fully enclosed automatic pot loading system includes a reaction kettle 1, an air outlet pipe 2, an air outlet connecting pipe 3, a linkage valve frame structure 4, a sealed feeding hopper 5, a sealed connection frame structure 6, and a first-stage exhaust gas neutralization frame structure 7 , support legs 8, intermediate connecting pipe 9, secondary waste gas neutralization frame structure 10, photo-oxygen waste gas purifier 11, waste gas pipe 12, clamshell fan frame structure 13, slag discharge pipe 14 and solenoid valve 15, the described The gas outlet pipe 2 is welded on the upper part of the reactor 1; the gas outlet connecting pipe 3 is flanged on the upper part of the gas outlet pipe 2; the linkage valve frame structure 4 is installed on the outer left side of the gas outlet connecting pipe 3; The sealed feed hopper 5 is welded on the lower left side of the outlet connecting pipe 3; the sealed connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com