Rare earth metal calendaring forming device and implementation method thereof

A technology of calendering and rare earth metals, which is applied in metal rolling, metal rolling, metal rolling racks, etc., can solve the problems of long rolling cycle time, troublesome manual operation, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

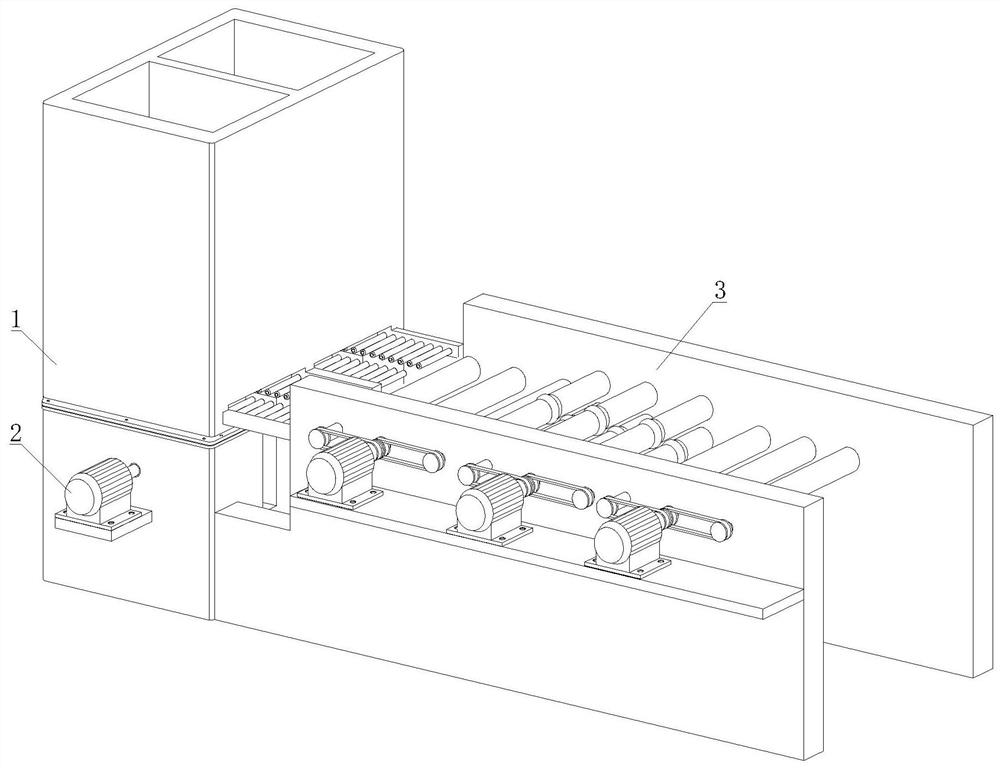

Image

Examples

Embodiment approach

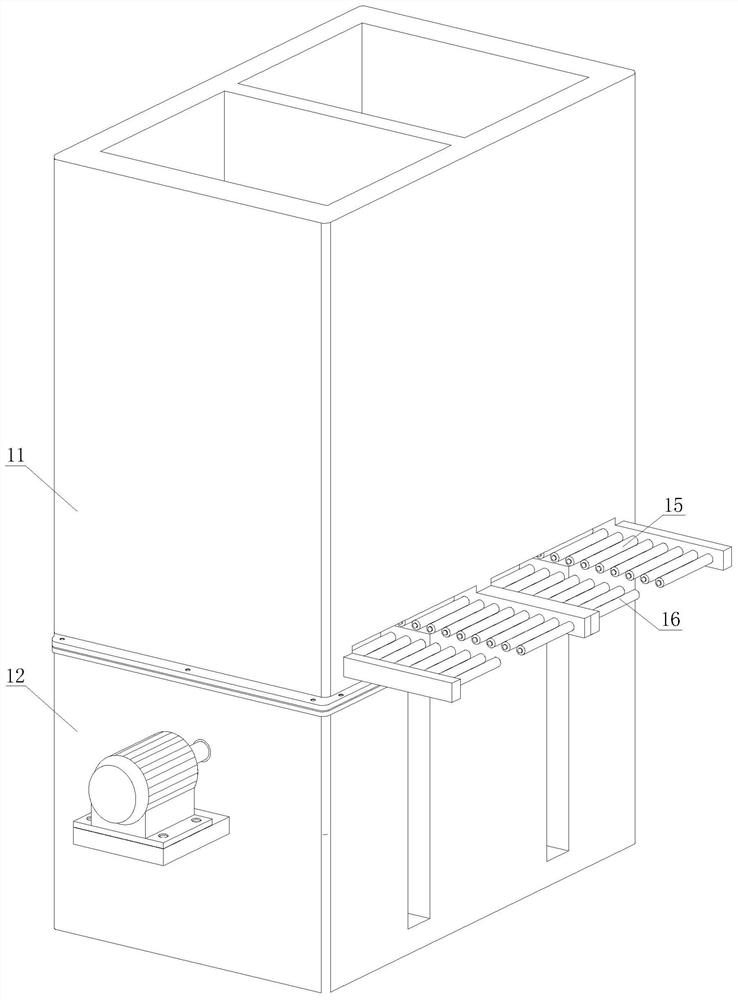

[0043] In order to better demonstrate the calendering process of rare earth metals, this embodiment now proposes an implementation method of a calendering device for rare earth metals, including the following steps:

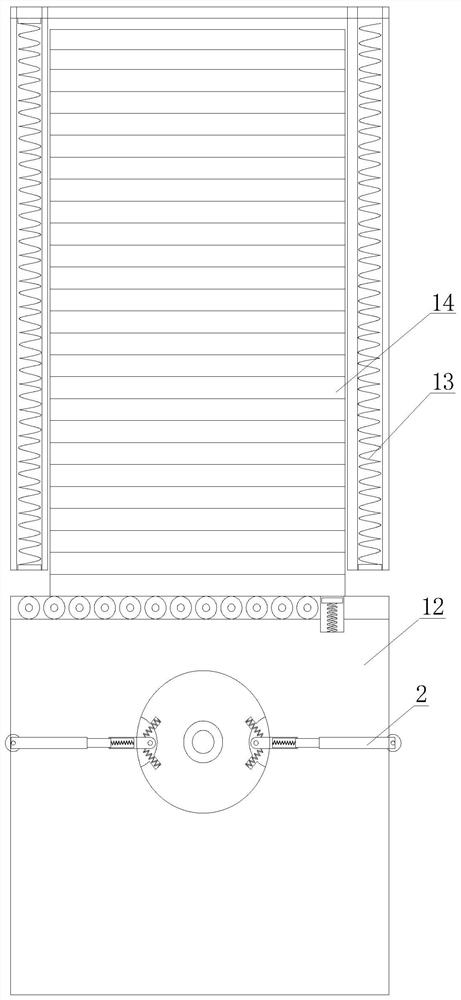

[0044] Step 1: first stack the rare earth metal plates 14 on the inside of the heating case shell 11 in sequence, and then electrify the heating wire 13, the heating temperature is 350-480 degrees, and the heating time is 1-2 hours;

[0045] Step 2: After the heating time is up, under the drive of the first motor 21, the first pushing assembly 23 and the second pushing assembly 24 rotate, and the upper end of the pushing connecting rod 234 will push the rare earth metal plate 14 outward to realize Automatic push;

[0046] Step 3: The rare earth metal plate 14 that is pushed out is driven by the second motor 331, and the rare earth metal plate 14 moves into the calendering assembly 34;

[0047] Step 4: The rare earth metal plate 14 moves to the calendering assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com