Coal gasification grey water treatment zero-discharge system

A zero-discharge, gray water technology, applied in the field of water treatment, can solve problems such as water pollution, waste of water resources, equipment scaling and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

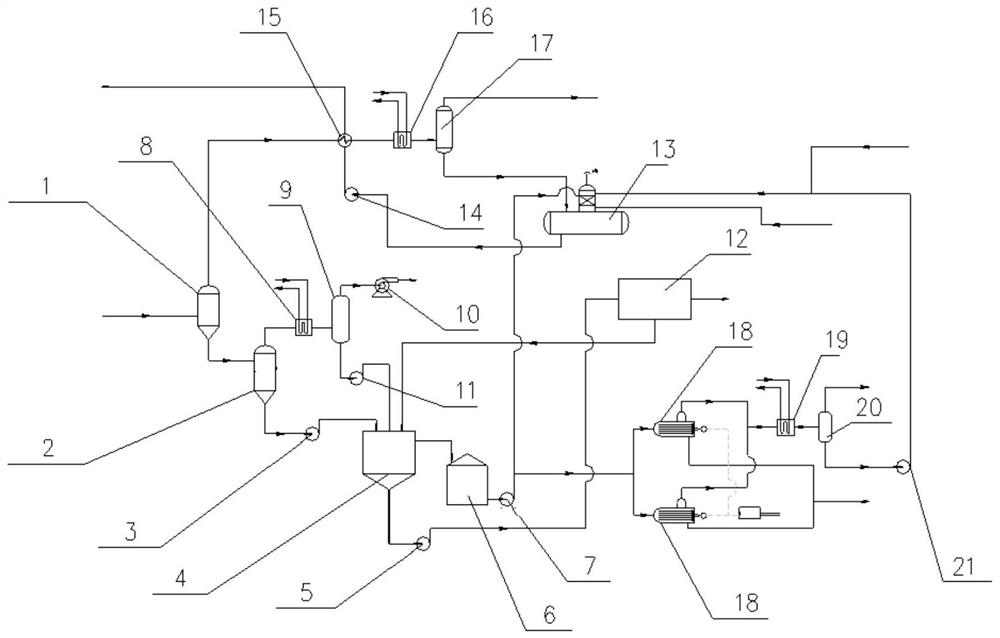

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

[0025] refer to figure 1 , the coal gasification ash water treatment zero discharge system of the present invention comprises a slag water input pipeline, a medium pressure flash tank 1, a vacuum flash tank 2, a clarification tank 4, an evaporation furnace 18, a deaerator 13, and an evaporative cooler 19 , evaporation liquid separation tank 20, gray water heater 15, medium pressure flash evaporation cooler 16, medium pressure flash evaporation liquid separation tank 17, vacuum flash evaporation cooler 8, vacuum flash evaporation liquid separation tank 9 and vacuum filter 12; The slag water input pipeline is connected with the inlet of the medium pressure flash tank 1, the liquid outlet at the bottom of the medium pressure flash tank 1 is connected with the inlet of the vacuum flash tank 2, and the liquid outlet at the bottom of the vacuum flash tank 2 is connected with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap