Polypropylene-based chlorine element/polybrominated diphenyl ether/heavy metal mixed standard sample and preparation method thereof

A technology of polypropylene-based chlorine elements and polybrominated diphenyl ethers, applied in the preparation of test samples, plastic recycling, recycling technology, etc., can solve problems such as uneven dispersion, poor appearance of standard products, and uneven content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

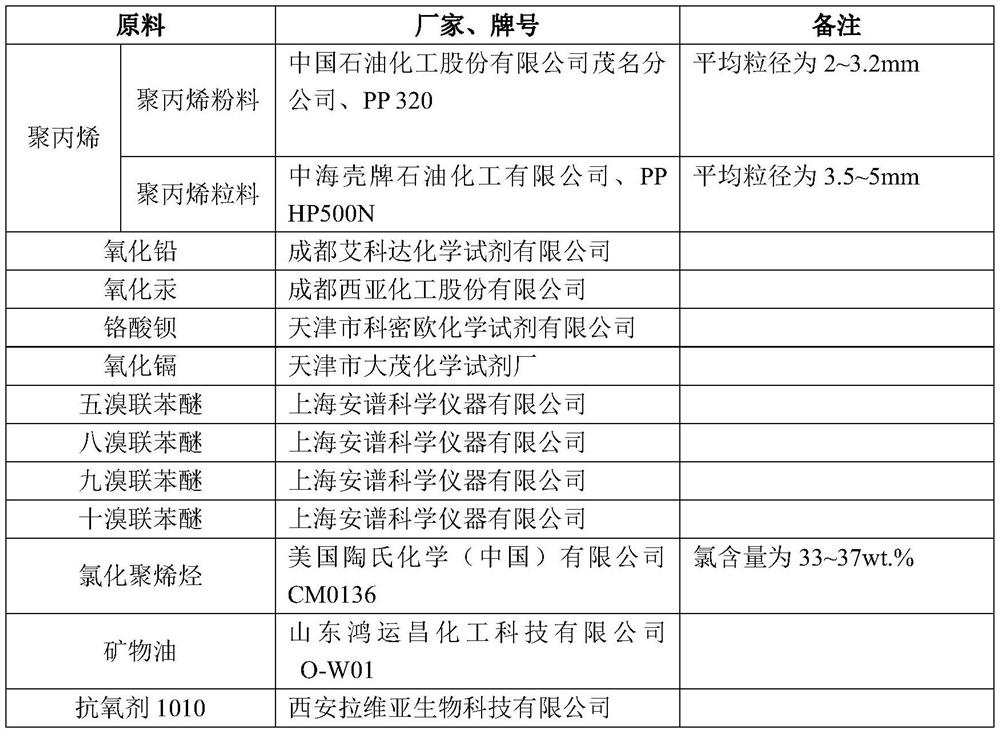

[0045] Embodiment 1 provides a kind of polypropenyl chlorine element, polybrominated diphenyl ether and heavy metal mixed standard sample, and preparation method is:

[0046] S1. Put lead oxide 21g, mercury oxide 31.58g, barium chromate 95g, cadmium oxide 33.41g, pentabromodiphenyl ether 27.53g, octabromodiphenyl ether 24.42g, nonabromodiphenyl ether 23.84g, decabromobiphenyl 163.85g of ether and 445.71g of chlorinated polyolefin were blended to obtain the first mixture;

[0047] S2. Blending the first mixture with 14073.64g of polypropylene, 15g of mineral oil, and 45g of antioxidant to obtain a second mixture, wherein polypropylene is a mixture of 1407.36g of polypropylene powder and 12666.28g of polypropylene pellets, That is, the polypropylene powder accounts for 10wt.% of the polypropylene weight;

[0048] S3. Add the second compound to the twin-screw extruder, melt and extrude and granulate to obtain the standard substance to be treated granules, wherein the screw lengt...

Embodiment 2

[0051] Embodiment 2 provides a kind of polypropenyl chlorine element, polybrominated diphenyl ether and heavy metal mixed standard sample, and the difference of preparation method and embodiment 1 is:

[0052] The polypropylene in S2 is a mixture of 7036.82 g of polypropylene powder and 7036.82 g of polypropylene pellets, that is, the polypropylene powder accounts for 20 wt.% of the polypropylene weight.

Embodiment 3

[0054]Embodiment 3 provides a kind of polypropenyl chlorine element, polybrominated diphenyl ether and heavy metal mixed standard sample, and the difference of preparation method and embodiment 1 is:

[0055] The polypropylene in S2 is a mixture of 13369.96 g of polypropylene powder and 703.68 g of polypropylene pellets, that is, the polypropylene powder accounts for 50 wt.% of the polypropylene weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com