Extraction and separation device of dissolving solution for neodymium iron boron waste recovery

A waste recycling and separation device technology, applied in the direction of improving process efficiency, can solve the problems of large number of pumps used, large space occupation, and high maintenance costs in the later period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

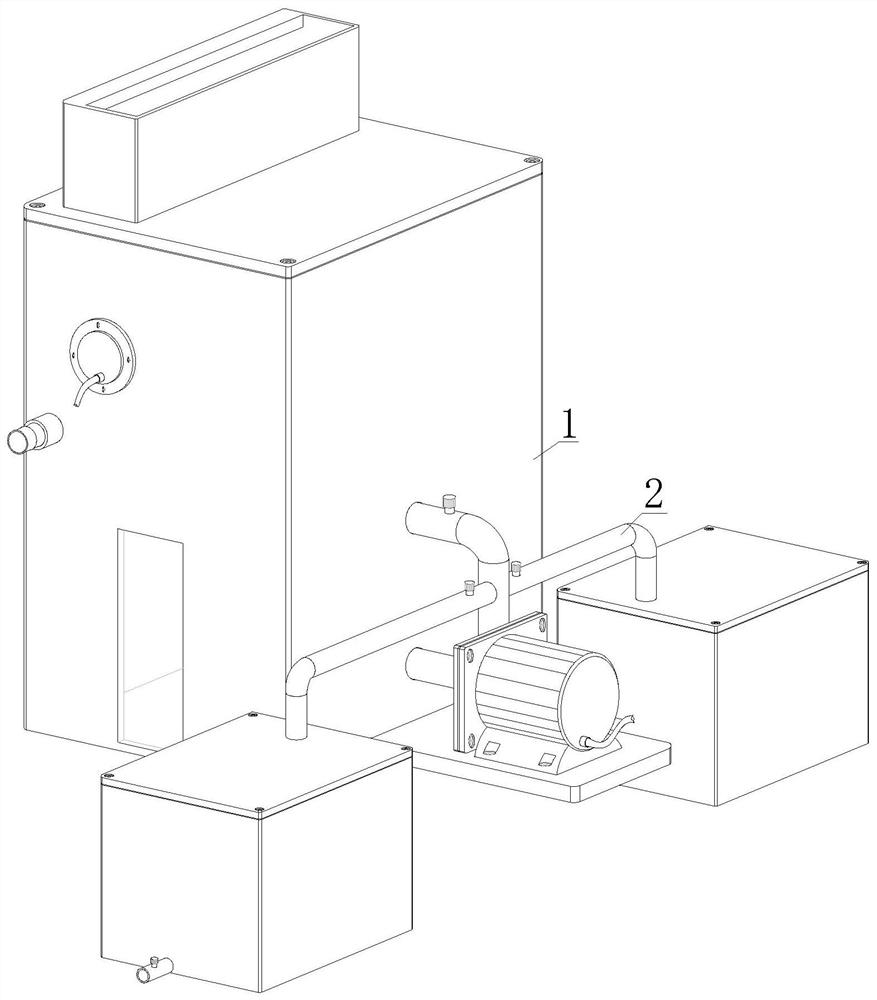

[0032] see figure 1 , an extraction and separation device for a solution solution for recycling NdFeB waste, comprising an extraction mechanism 1 and a circulation mechanism 2, one end of the circulation mechanism 2 is arranged inside the extraction mechanism 1, and the other end of the circulation mechanism 2 is arranged at the side of the extraction mechanism 1 side.

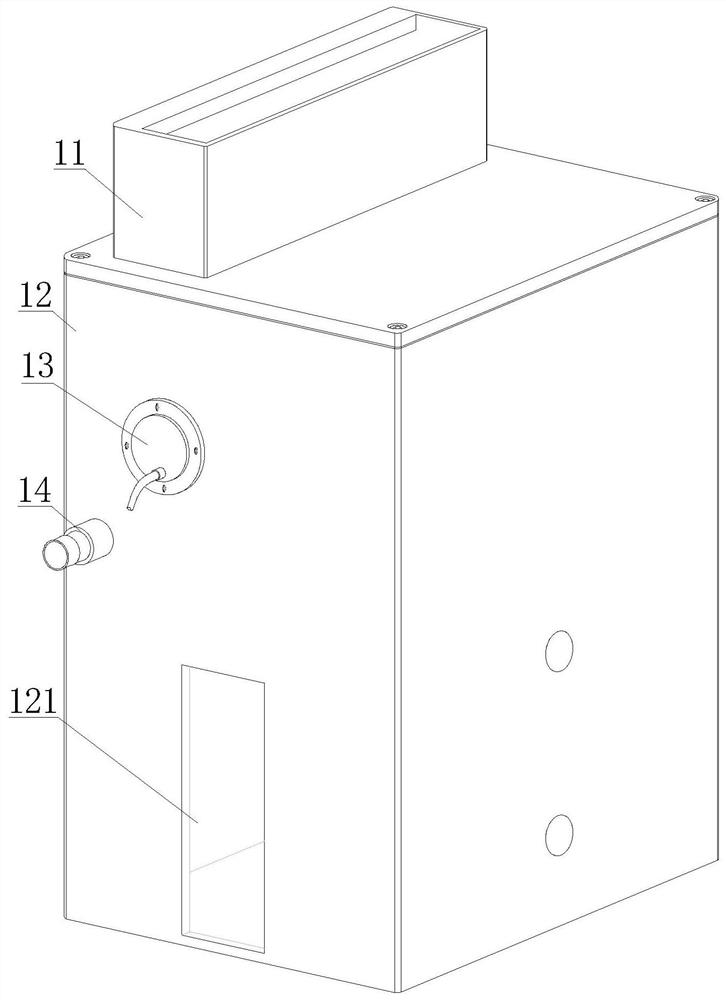

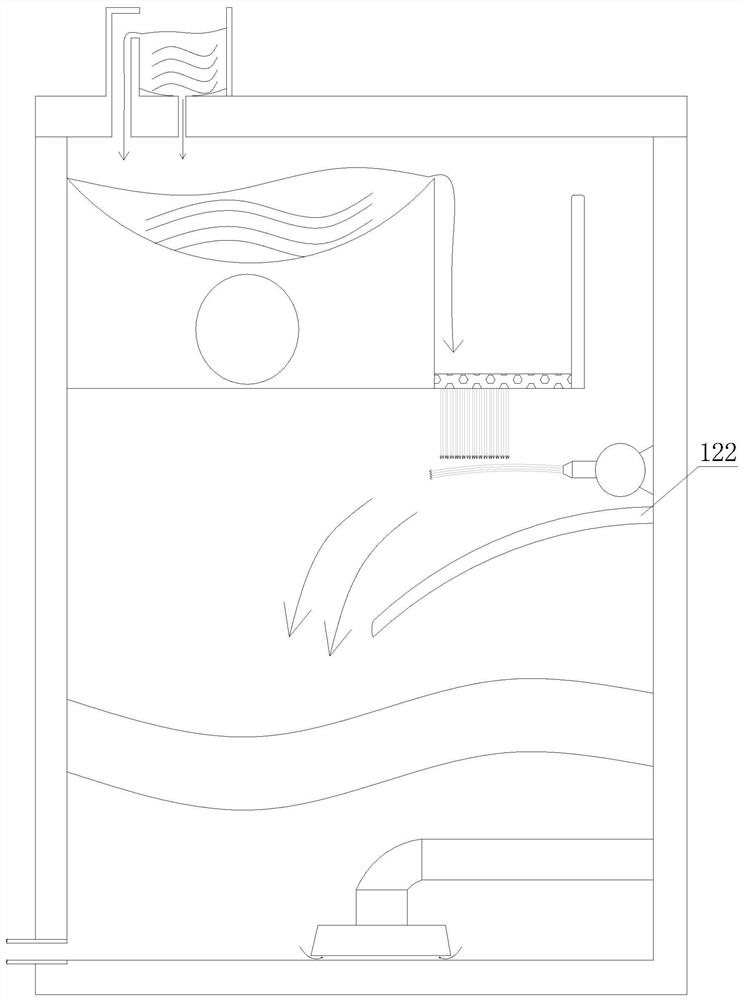

[0033] see Figure 2-5 , a kind of NdFeB waste recycling solution extraction and separation device, the extraction mechanism 1 includes the solution into the box 11, the extraction box 12, the impurity removal mechanism 13 and the extraction agent adding connecting pipe 14, the solution into the box 11 is set On the upper side of the extraction box 12, the impurity removal mechanism 13 is arranged at the upper end of the inner cavity of the extraction box 12, and the extractant addition connecting pipe 14 is located at the lower end of the impurity removal mechanism 13 and is arranged on one side of the extra...

Embodiment 2

[0041] see figure 1 , an extraction and separation device for a solution solution for recycling NdFeB waste, comprising an extraction mechanism 1 and a circulation mechanism 2, one end of the circulation mechanism 2 is arranged inside the extraction mechanism 1, and the other end of the circulation mechanism 2 is arranged at the side of the extraction mechanism 1 side.

[0042] see Figure 2-5 , a kind of NdFeB waste recycling solution extraction and separation device, the extraction mechanism 1 includes the solution into the box 11, the extraction box 12, the impurity removal mechanism 13 and the extraction agent adding connecting pipe 14, the solution into the box 11 is set On one side of the upper end of the extraction case 12, the impurity removal mechanism 13 is arranged on the inner cavity upper end of the extraction case 12, and the extractant addition connecting pipe 14 is positioned at the lower end of the impurity removal mechanism 13 and is arranged on one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com