Preparation method of 7XXX series aluminum alloy bar based on mechanical ultrasonic vibration aging

An ultrasonic vibration, aluminum alloy technology, applied in the field of aluminum alloy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

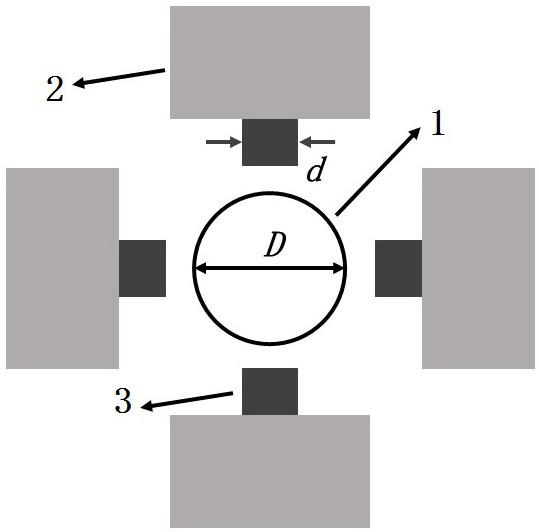

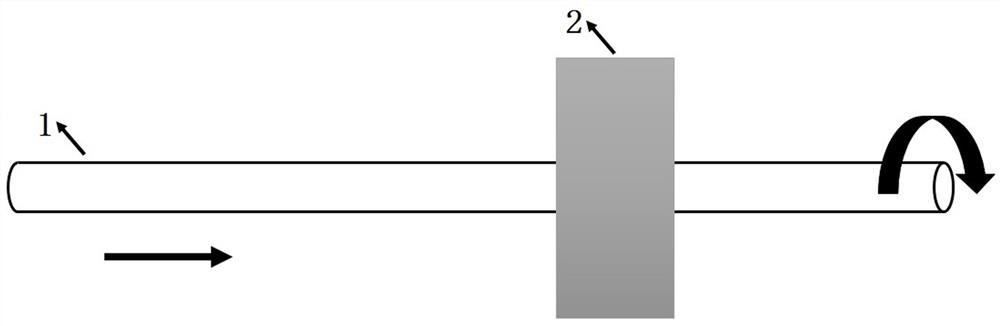

[0032] The 7050 aluminum alloy ingot was homogenized at 470°C for 20 hours, then air-cooled; the air-cooled ingot was hot-extruded at 480°C, the extrusion ratio was 35, the extrusion speed was 1m / min, and water-cooled after extrusion , the diameter of the rod 1 obtained is 3cm; the hot extruded rod 1 is rotated through the mechanical ultrasonic vibration device 2 at a fixed position, the diameter of the cylindrical ultrasonic indenter 3 is 0.5cm, and the work of the ultrasonic indenter 3 The frequency is 20kHz, the maximum contact stress is 80N, the rotation speed of bar 1 is 3.18 rpm, and the forward speed of bar 1 is 6.37cm / min. After processing, a 7XXX series aluminum alloy bar based on mechanical ultrasonic vibration aging is obtained.

Embodiment 2

[0034] The 7050 aluminum alloy ingot was homogenized at 460°C for 6 hours, then air-cooled; the air-cooled ingot was hot-extruded at 470°C, the extrusion ratio was 15, the extrusion speed was 0.6m / min, and water-cooled after extrusion Processing, the diameter that obtains rod 1 is 20cm; The rod 1 after hot extrusion is rotated through the mechanical ultrasonic vibrating device 2 that is positioned at fixed position, and the diameter of cylindrical ultrasonic indenter 3 is 3cm, and the work of ultrasonic indenter 3 The frequency is 20kHz, the maximum contact stress is 100N, the rotation rate of bar 1 is 2.86 rpm, and the forward speed of bar 1 is 34.38cm / min. After processing, a 7XXX series aluminum alloy bar based on mechanical ultrasonic vibration aging is obtained.

Embodiment 3

[0036]The 7050 aluminum alloy ingot was homogenized at 480°C for 24 hours, then air-cooled; the air-cooled ingot was hot-extruded at 460°C, the extrusion ratio was 25, the extrusion speed was 1.2m / min, and water-cooled after extrusion Processing, the diameter that obtains rod 1 is 5cm; The rod 1 after hot extrusion is rotated through the mechanical ultrasonic vibrating device 2 that is positioned at fixed position, and the diameter of cylindrical ultrasonic indenter 3 is 0.5cm, and the diameter of ultrasonic indenter 3 The working frequency is 20kHz, the maximum contact stress is 60N, the rotation speed of bar 1 is 1.91 rpm, and the forward speed of bar 1 is 3.82cm / min. After the processing is completed, a 7XXX series aluminum alloy bar based on mechanical ultrasonic vibration aging is obtained. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com