A preparation method of 7xxx series aluminum alloy rods based on mechanical ultrasonic vibration aging

An ultrasonic vibration, aluminum alloy technology, applied in the field of aluminum alloy processing, to achieve the effect of plasticity improvement, small roughness, and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

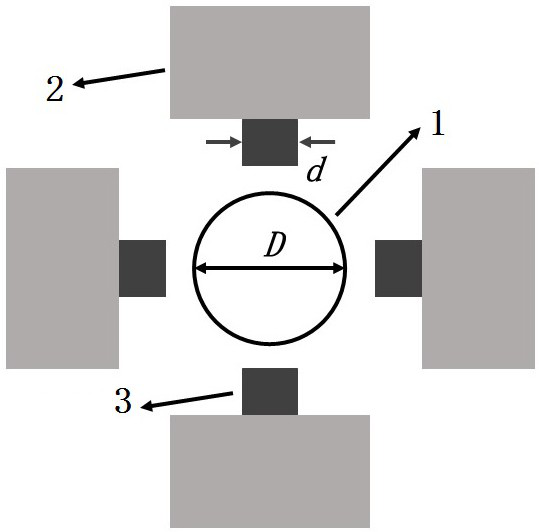

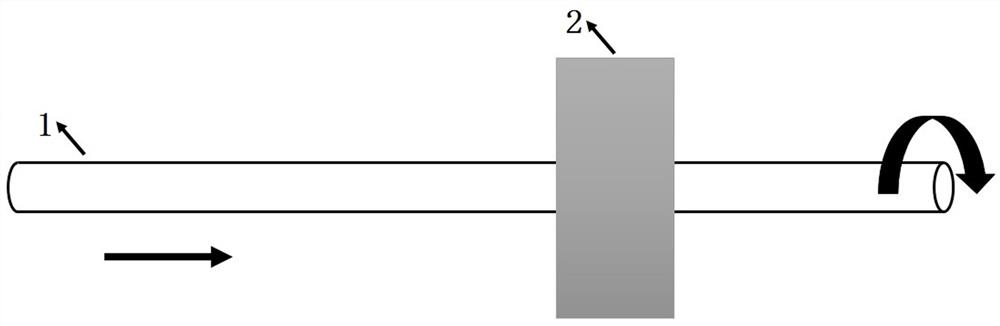

[0032] The 7050 aluminum alloy ingot was homogenized at 470°C for 20 hours, then air-cooled; the air-cooled ingot was hot-extruded at 480°C, the extrusion ratio was 35, the extrusion speed was 1m / min, and water-cooled after extrusion , the diameter of the rod 1 obtained is 3cm; the hot extruded rod 1 is rotated through the mechanical ultrasonic vibration device 2 at a fixed position, the diameter of the cylindrical ultrasonic indenter 3 is 0.5cm, and the work of the ultrasonic indenter 3 The frequency is 20kHz, the maximum contact stress is 80N, the rotation speed of bar 1 is 3.18 rpm, and the forward speed of bar 1 is 6.37cm / min. After processing, a 7XXX series aluminum alloy bar based on mechanical ultrasonic vibration aging is obtained.

Embodiment 2

[0034] The 7050 aluminum alloy ingot was homogenized at 460°C for 6 hours, then air-cooled; the air-cooled ingot was hot-extruded at 470°C, the extrusion ratio was 15, the extrusion speed was 0.6m / min, and water-cooled after extrusion Processing, the diameter that obtains rod 1 is 20cm; The rod 1 after hot extrusion is rotated through the mechanical ultrasonic vibrating device 2 that is positioned at fixed position, and the diameter of cylindrical ultrasonic indenter 3 is 3cm, and the work of ultrasonic indenter 3 The frequency is 20kHz, the maximum contact stress is 100N, the rotation rate of bar 1 is 2.86 rpm, and the forward speed of bar 1 is 34.38cm / min. After processing, a 7XXX series aluminum alloy bar based on mechanical ultrasonic vibration aging is obtained.

Embodiment 3

[0036]The 7050 aluminum alloy ingot was homogenized at 480°C for 24 hours, then air-cooled; the air-cooled ingot was hot-extruded at 460°C, the extrusion ratio was 25, the extrusion speed was 1.2m / min, and water-cooled after extrusion Processing, the diameter that obtains rod 1 is 5cm; The rod 1 after hot extrusion is rotated through the mechanical ultrasonic vibrating device 2 that is positioned at fixed position, and the diameter of cylindrical ultrasonic indenter 3 is 0.5cm, and the diameter of ultrasonic indenter 3 The working frequency is 20kHz, the maximum contact stress is 60N, the rotation speed of bar 1 is 1.91 rpm, and the forward speed of bar 1 is 3.82cm / min. After the processing is completed, a 7XXX series aluminum alloy bar based on mechanical ultrasonic vibration aging is obtained. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com