Box-type high-temperature gas filter

A high-temperature gas and filter technology, which is applied in membrane filters, dispersed particle filtration, chemical instruments and methods, etc., can solve the problem of large gas resistance in test tube structure, required distance between filter elements, easy residual filter cake in backflushing, etc. problems, to achieve the effect of avoiding dust bridging, small running resistance and high blowback efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

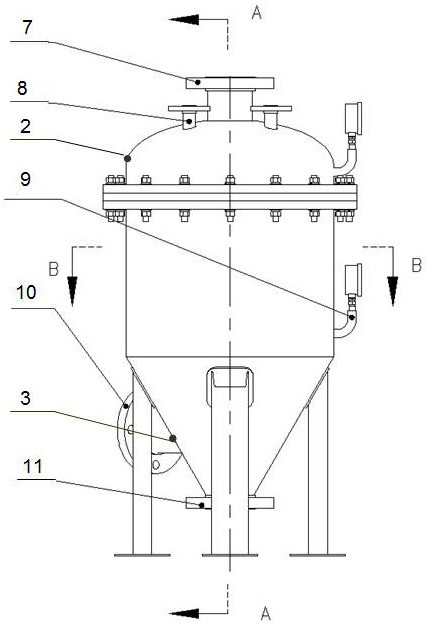

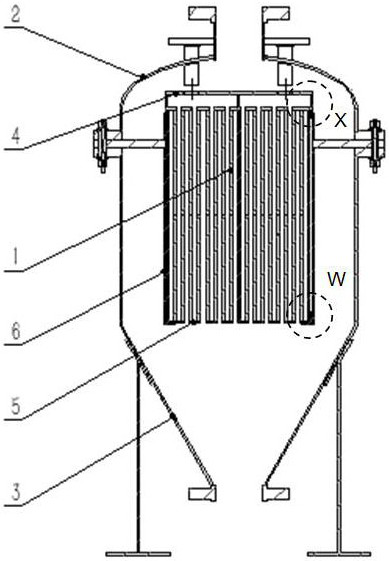

[0042] Such as Figure 1 to Figure 3 As shown, the box-type high-temperature gas filter includes a filter housing and a box-type honeycomb filter unit sealed in the filter housing. In this embodiment, there is only one box-type honeycomb filter unit in the filter housing. In actual production, according to Multiple box-type honeycomb filter units can be set up if required, among which:

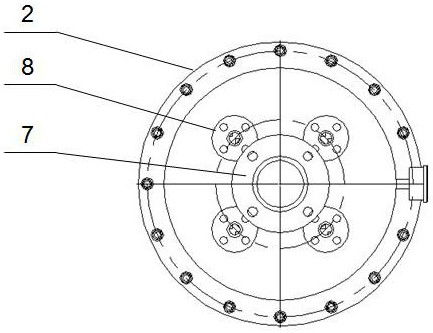

[0043] The cross section of the filter housing is circular. The filter housing is divided into an upper housing 2 and a lower housing 3. The upper housing 2 and the lower housing 3 are sealed and connected by flanges. The upper housing 2 is provided with an air outlet directly above the top. 7. An air inlet 10 is provided on the side of the bottom of the lower shell 3, and a slag discharge port 11 is provided directly below the bottom of the lower shell 3; at the same time, the blowback pipe 8 is welded on the top of the upper shell 2, such as figure 2 As shown, four blowback pipes 8 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com