An ultra-high-porosity hafnium-tantalum-niobium ternary carbide ultra-high temperature thermal insulation material and its preparation method

A ternary carbide and thermal insulation material technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of high thermal conductivity, low strength, low porosity of porous materials, etc., to achieve high porosity, High product performance and excellent ultra-high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

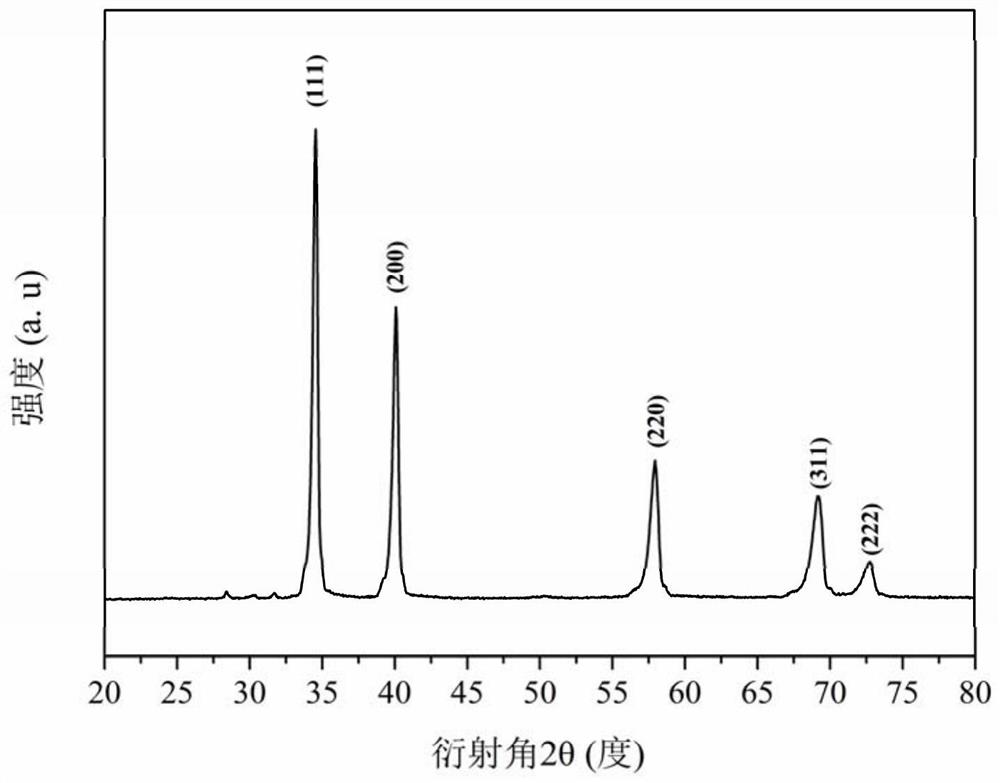

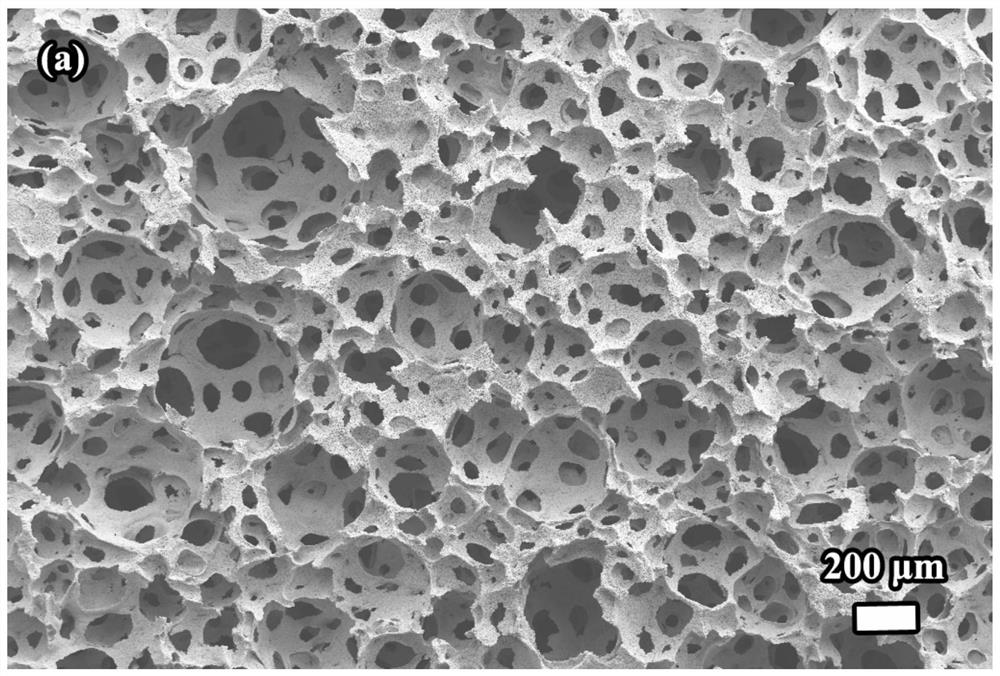

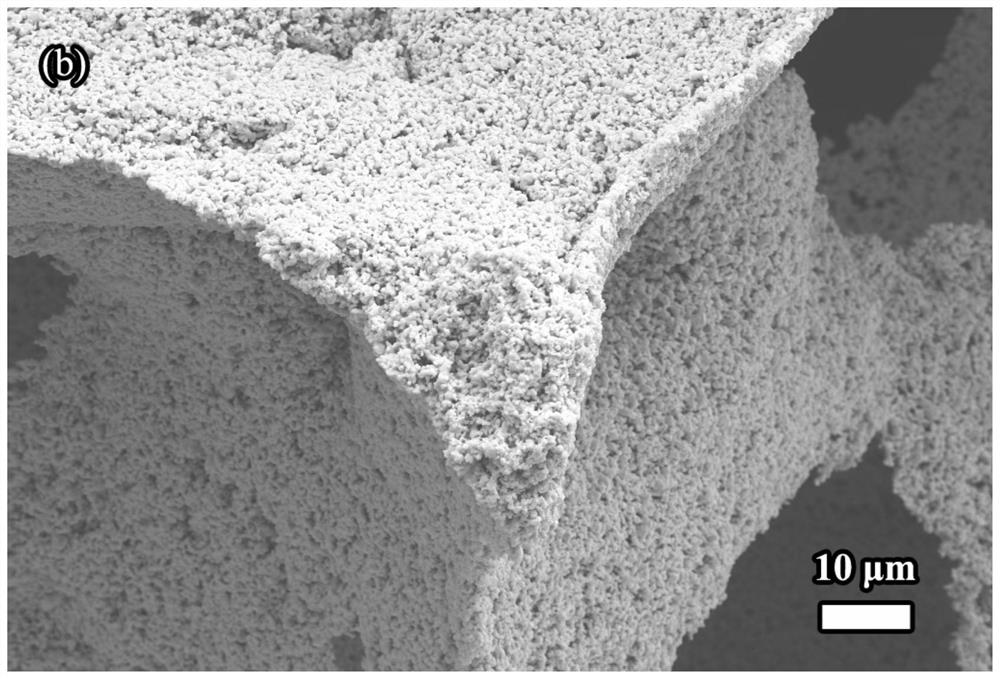

[0029] In this example, the preparation method of the ultra-high-porosity hafnium-tantalum-niobium ternary carbide ultra-high temperature insulation material is as follows:

[0030] 1) Preparation of ceramic slurry: Weigh 21 grams of deionized water, 2.5 grams of polyacrylic acid, and 140 grams of hafnium carbide, tantalum carbide and niobium carbide mixed powder with a molar ratio of 1:2:3, add them in sequence and stir After 3 hours, a slurry with evenly dispersed ceramic particles is formed; among them, the original particle size of the raw material hafnium carbide powder is 0.5-1.5 μm, the original particle size of the raw material tantalum carbide powder is 2-3 μm, and the original particle size of the raw material niobium carbide powder is 2-3 μm ; After ball milling for 10 hours, the average particle size of the mixed powder is about 1 μm.

[0031]2) Foaming-gel injection molding: heat the above slurry to 38°C, add 3 grams of sodium lauryl sulfate, and stir and foam at ...

Embodiment 2

[0036] In this example, the preparation method of the ultra-high-porosity hafnium-tantalum-niobium ternary carbide ultra-high temperature insulation material is as follows:

[0037] 1) Preparation of ceramic slurry: Weigh 45 grams of deionized water, 2 grams of ammonium citrate, and 85 grams of mixed powder of hafnium carbide, tantalum carbide and niobium carbide at a molar ratio of 1:1:2, and add them in sequence. Stir for 2 hours to form a slurry with evenly dispersed ceramic particles; wherein, the original particle size of the raw material hafnium carbide powder is 0.5-1.5 μm, the original particle size of the raw material tantalum carbide powder is 0.5-1.5 μm, and the original particle size of the raw material niobium carbide powder is 0.5 ~1.5μm; after ball milling for 36 hours, the average particle size of the mixed powder is about 0.7μm.

[0038] 2) Foaming-gel injection molding: heat the above slurry to 50°C, add 1.5 grams of sodium dodecylsulfonate, and stir and foam...

Embodiment 3

[0043] In this example, the preparation method of the ultra-high-porosity hafnium-tantalum-niobium ternary carbide ultra-high temperature insulation material is as follows:

[0044] 1) Preparation of ceramic slurry: Weigh 25 grams of deionized water, 1.5 grams of polyacetimide, and 115 grams of hafnium carbide, tantalum carbide and niobium carbide mixed powder with a molar ratio of 1:1:1, and add in sequence and stirred for 1 hour to form a slurry with evenly dispersed ceramic particles; wherein, the original particle size of the raw material hafnium carbide powder is 0.5-1.5 μm, the original particle size of the raw material tantalum carbide powder is 1-2 μm, and the original particle size of the raw material niobium carbide powder is 1 ~2μm; after ball milling for 24 hours, the average particle size of the mixed powder is about 0.8μm.

[0045] 2) Foaming-gel injection molding: heat the above slurry to 40°C, then add 2 grams of sodium lauryl sulfate, and quickly mechanically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com