Method for centrifugally binding ITO rotating target

A rotating target and binding technology, applied in ion implantation plating, metal material coating process, vacuum evaporation plating, etc., can solve problems such as difficulties, easy to cause voids, and increase in resistance, achieve good results and improve product quality , Improve the effect of welding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

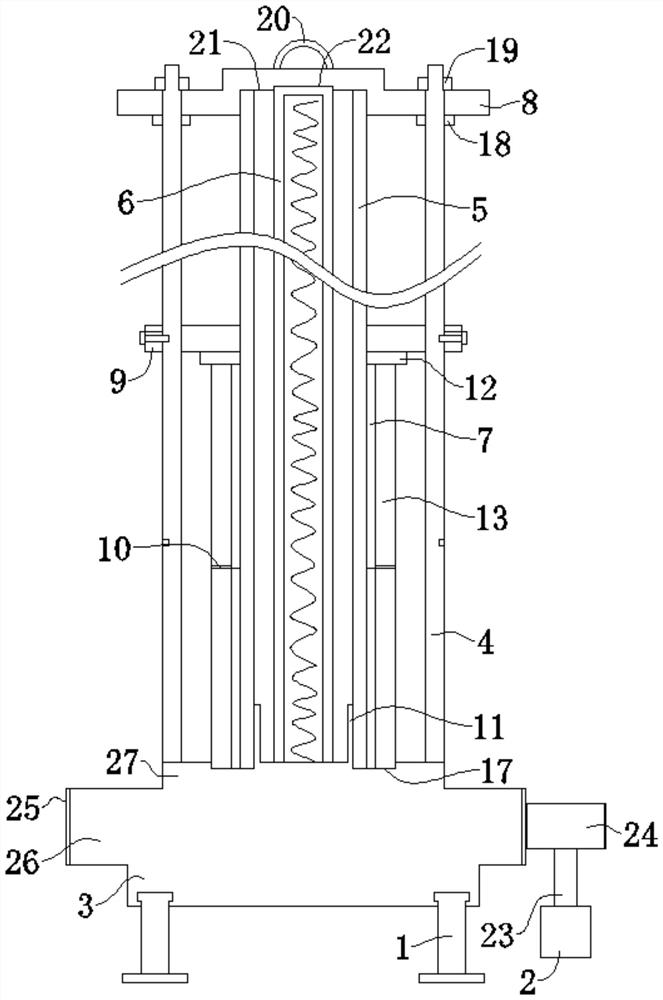

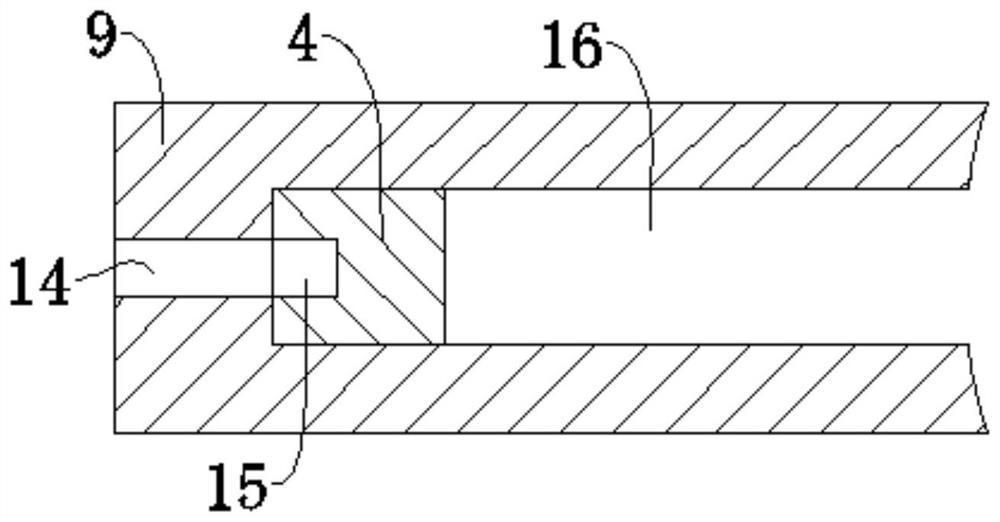

[0031] Embodiment: a kind of method of centrifugal binding ITO rotating target material, such as Figure 1-2 shown, including the following steps:

[0032] S1, preprocessing

[0033] The inner wall of the ITO target tube 13 and the outer surface of the back tube 5 are metallized, the ITO target tube 13 and the back tube 5 are both cylindrical, and the inner diameter of the ITO target tube 13 matches the back tube 5 .

[0034] The metallization process of the inner wall of the ITO target tube 13 is as follows:

[0035] Paste transparent high-temperature-resistant tape on the outer surface and both sides of the ITO target tube 13, and then put it into a tubular heating furnace for heating. The inner wall of the ITO target tube 13 is moved on the inner wall of the ITO target tube 13 with an arc-shaped ultrasonic gun head to perform ultrasonic injection, so that an indium layer with a thickness of 0.1-0.2 mm is formed on the inner wall of the ITO target tube 13 .

[0036] Prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com