Process and device for improving adsorption performance of active palladium on surface of electroplating-grade plastic part

A technology with surface activity and adsorption performance, applied in the direction of electrolytic components, electrolysis process, etc., can solve the problems of incomplete spraying, poor applicability of plastic parts, and low spraying efficiency, so as to improve adsorption performance, reduce the proportion of plastic leaks, and improve The effect of adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

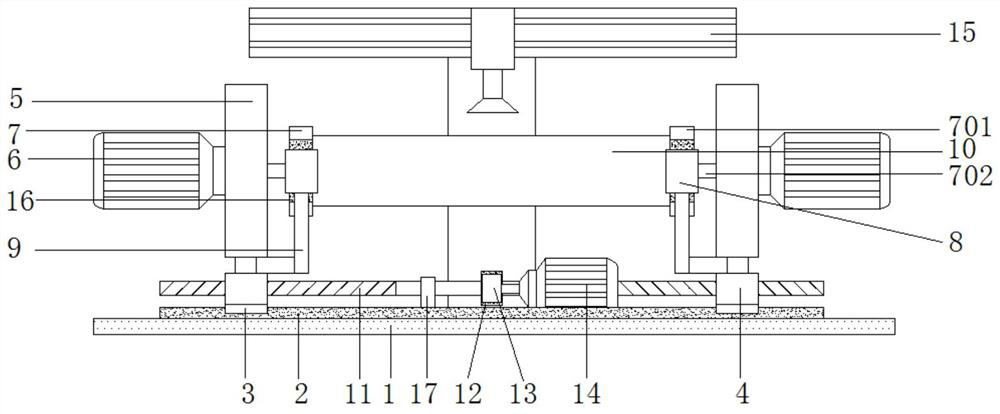

[0029] see figure 1 , a process for improving the adsorption performance of active palladium on the surface of electroplating grade plastic parts, comprising a plastic substrate 10, comprising the following steps;

[0030] S1. Perform ultrasonic degreasing, high-temperature degreasing and water washing on the plastic base material 10. Here, wash twice to remove oil stains on the surface of the plastic base material 1, and then carry out pickling and water washing on the degreasing plastic base material 10 in sequence. , where it is washed three times with water to obtain the specified surface roughness; specifically, after the plastic substrate 10 is hung up with a hanger, it is put into the ultrasonic control box and the high-temperature water tank, and both stay for 40 seconds. Material 1 is degreased, and after degreasing, it is washed once in two groups of pools, and the water stays for 5 seconds; after that, the plastic base material 10 is put into a pickling pool with a ...

Embodiment 2

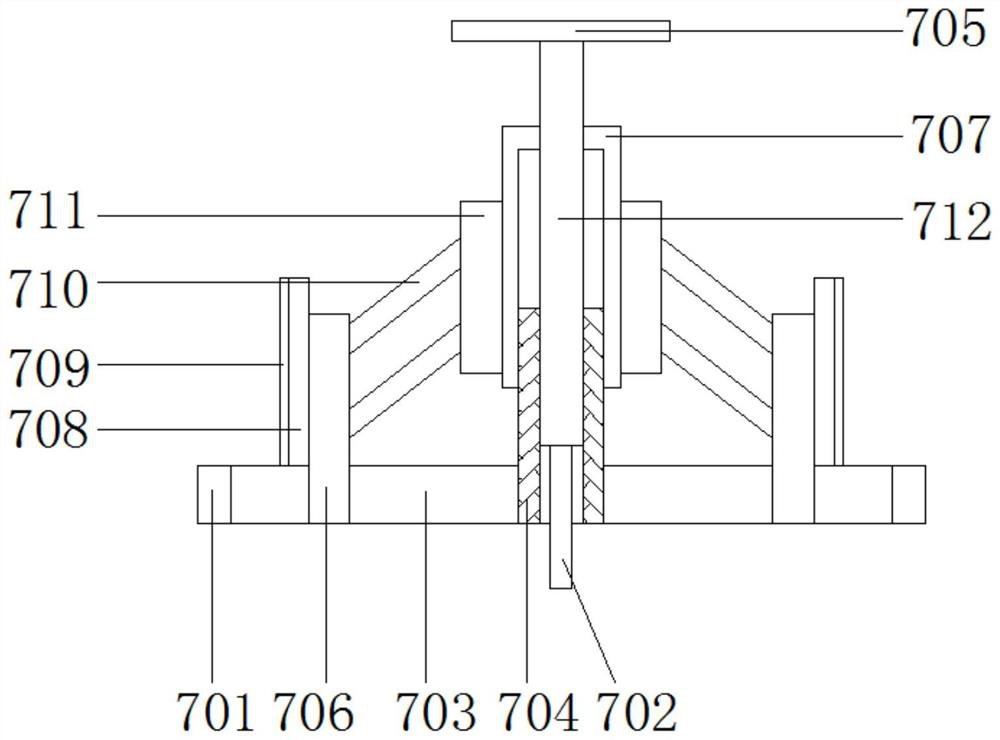

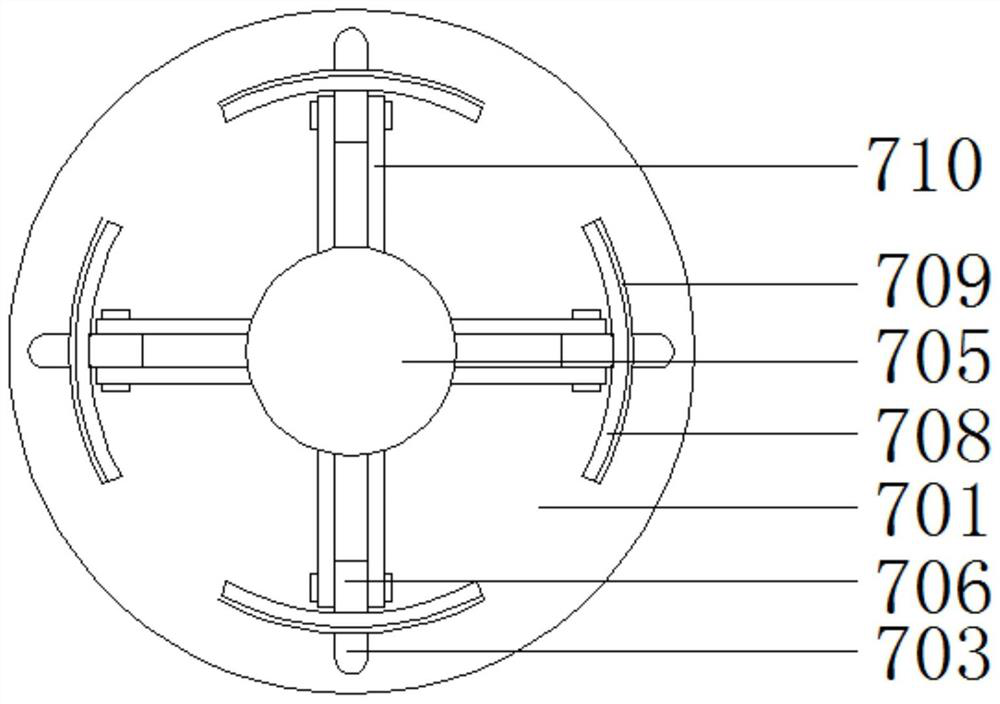

[0036] see Figure 1-4An electroplating device for nickel-plating the surface of a plastic substrate 10, including a base plate 1, the front and rear ends above the base plate 1 are fixedly connected with slide rails 2, and the left and right ends of the slide rail 2 are slidably connected with sliders 3, and every two groups of adjacent slides The top of the block 3 is fixedly connected with a bracket 4, and the middle of the bottom of the bracket 4 is threaded to be connected with a first screw 11, and the middle end of the first screw 11 is fixedly sleeved and connected with a first gear 12, and the front end of the first gear 12 is connected with a Second gear 13, the right side of second gear 13 is fixedly connected with second motor 14, and second motor 14 is fixedly connected with the upper right side of base plate 1; The plate 17 is fixedly connected with the base plate 1; the front and rear ends of the upper inner side of the bracket 4 are fixedly connected with a ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com