Nickel-titanium-niobium memory alloy fiber line externally-pasted prefabricated prestressed plate and construction method

A technology of memory alloy and nickel-titanium-niobium, which is applied in the field of prefabricated prestressed plate and construction of nickel-titanium-niobium memory alloy fiber line, which can solve the problem of backward bridge maintenance management decision-making system, aggravated bridge inspection, maintenance and reinforcement, and frequent bridge collapse accidents and other problems to achieve the effect of avoiding maintenance, convenient construction and replacement, and improving the quality of reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

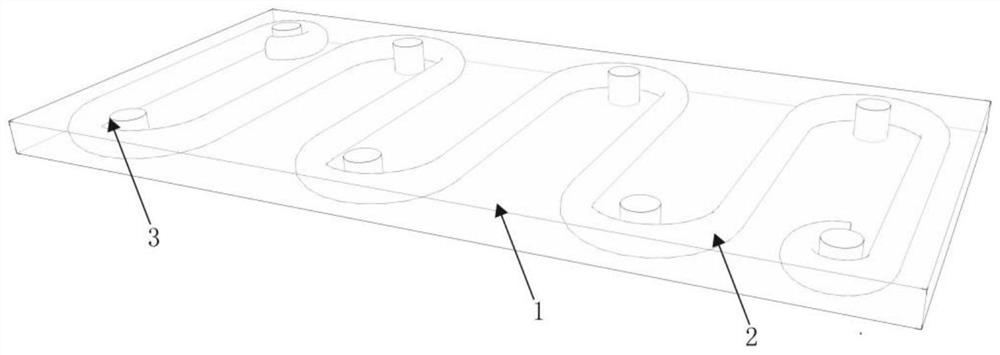

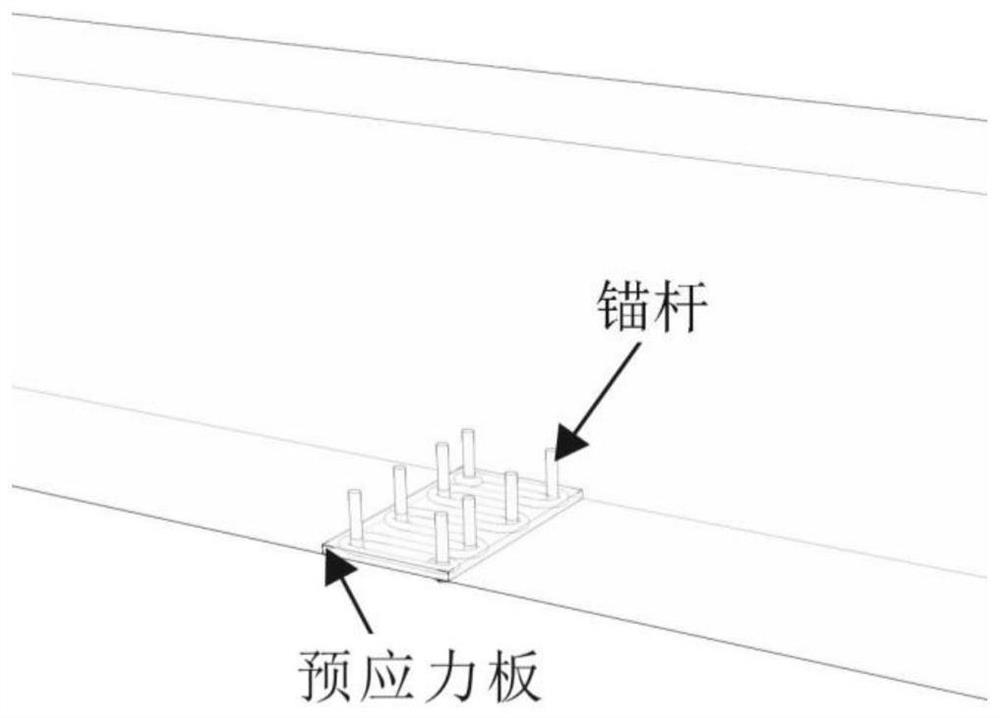

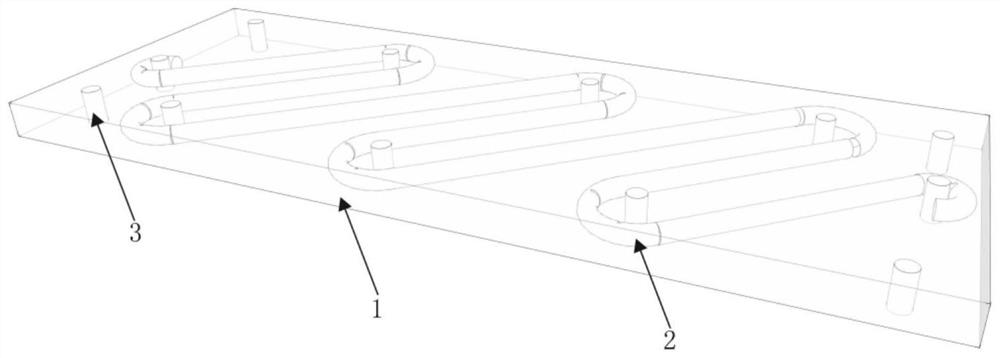

[0029] Such as figure 1 or image 3 As shown, the present invention is a prefabricated prestressed plate with nickel-titanium-niobium memory alloy fiber line externally attached, which includes a plate body 1 and a nickel-titanium-niobium memory alloy fiber line 2, the plate body 1 is formed by high-strength grouting material, nickel-titanium The niobium memory alloy fiber wire 2 is placed inside the plate body in a meandering shape, and the nickel-titanium niobium memory alloy fiber wire 2 includes a plurality of linear prestressing sections, and an arc is passed between two adjacent prestressing sections. Shaped anchorage sections are connected, and embedded steel sleeves 3 are respectively provided on the inner side of each anchorage section.

[0030] The surface of the nickel-titanium-niobium memory alloy fiber wire 2 has transverse ribs. The rib helps the nickel-titanium-niobium memory alloy fiber wire 2 to be anchored in the high-strength grouting material, and promote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com