Long-span slow bonded prestressed reinforced concrete beam and its construction method

A slow-bonded prestressed and reinforced concrete beam technology, which is applied in the fields of formwork/formwork/working frame, preparation of building components on site, and processing of building materials, can solve environmental pollution, difficulty in positioning prestressed tendons, and structural problems. Insufficient performance and other problems, to achieve the effect of convenient construction, simple and reasonable node layout, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

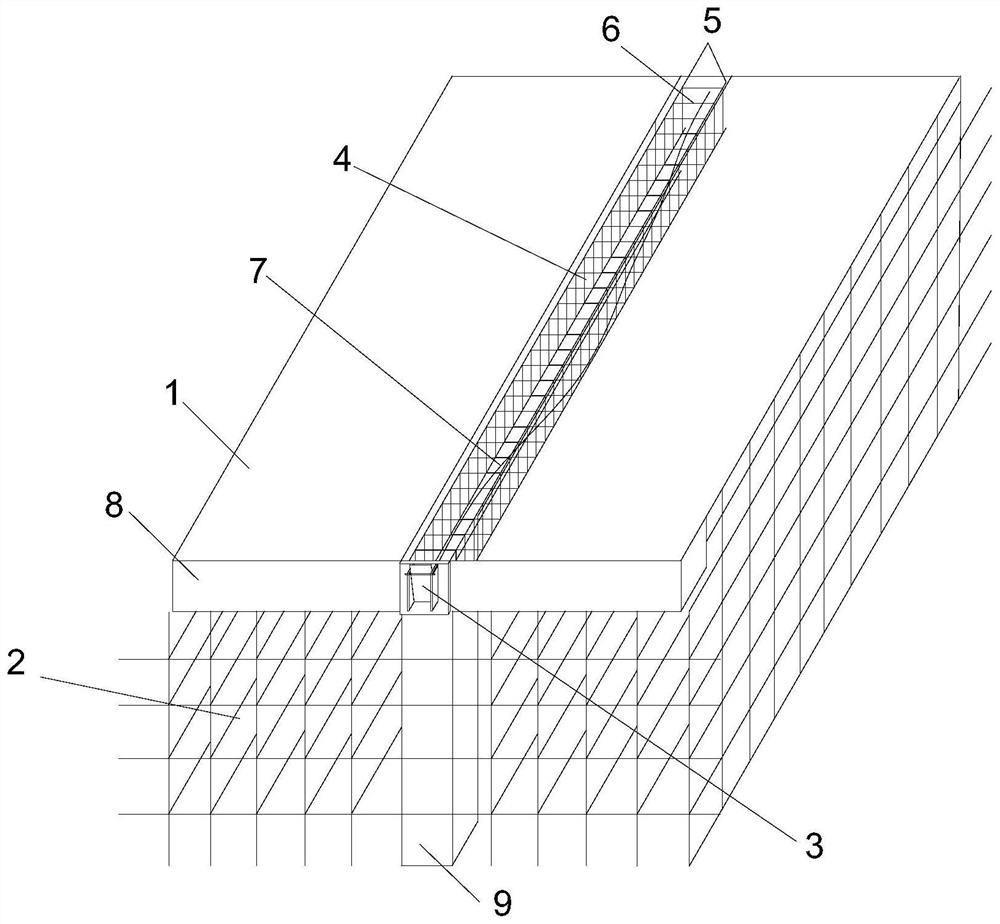

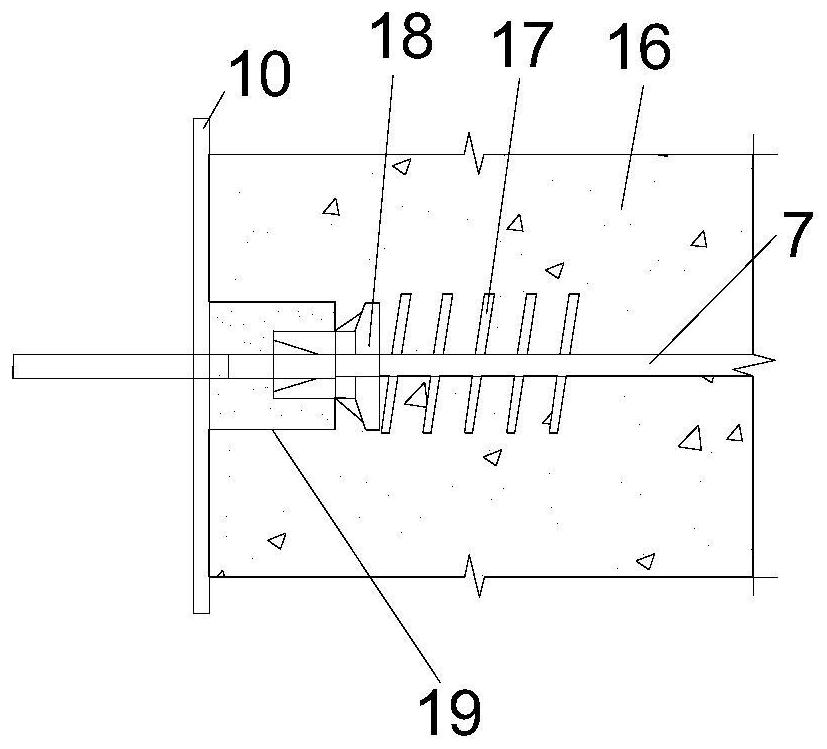

[0044] like Figure 1-10 As shown, the large-span slow-bonded prestressed reinforced concrete beam includes a large-span slow-bonded prestressed beam and a prestressed tendon positioning device.

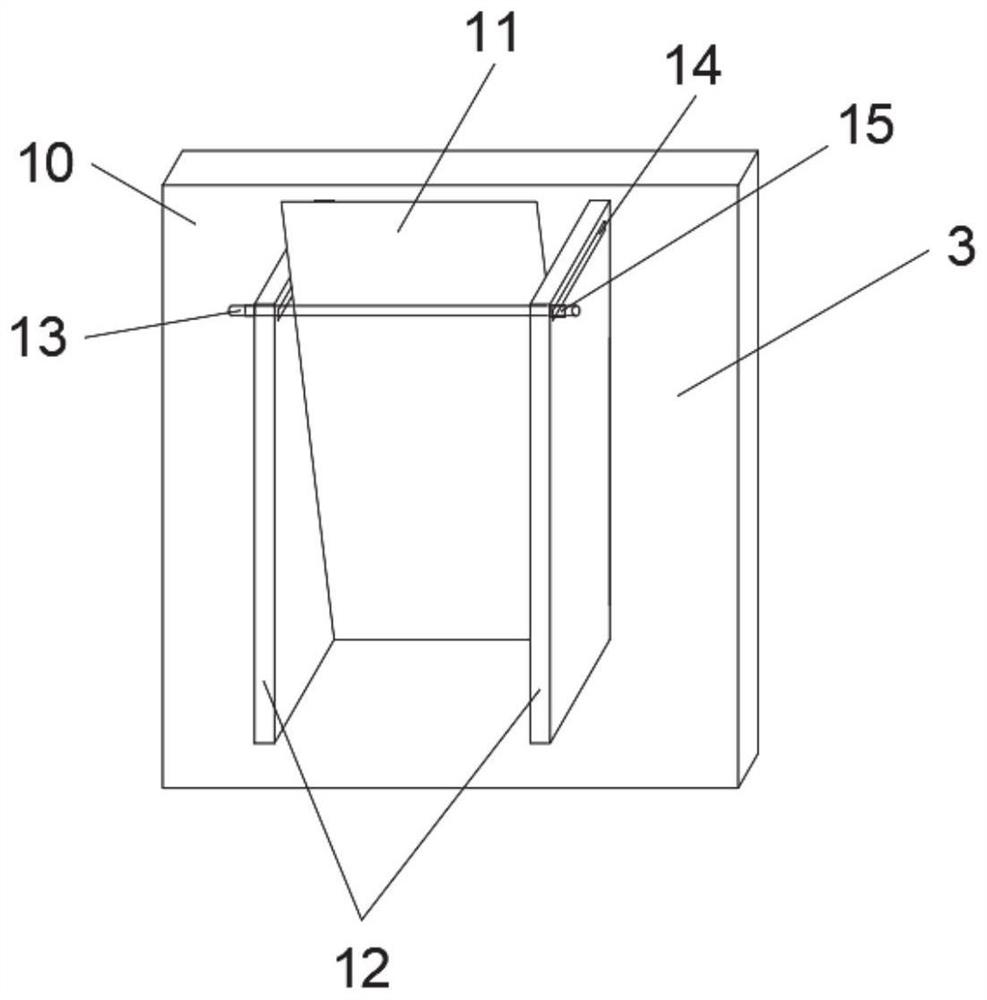

[0045] The long-span slow-bonded prestressed beam includes a formwork system, a support structure 2, a prestressed tension end member, a prestressed fixed end member, a beam reinforcement 4 and a slow-bonded prestressed tendon 7; the formwork system includes a plate. Formwork 1, tensioned end casting formwork 3, beam formwork 8, column formwork 9, beam formwork 8 is set on the side of the prestressed beam, plate formwork 1 is set on the upper part of the prestressed beam, and column formwork 9 is set below the prestressed beam; The formwork 1, the beam formwork 8 and the column formwork 9 are supported and fixed by the support structure 2, and the support structure 2 is erected by steel scaffolding; the tensioned end casting formwork 3 is a steel formwork, including the base plate 10...

Embodiment 2

[0055] The construction method of long-span slow-bonded prestressed reinforced concrete beams, the main steps are as follows:

[0056] S1: Construction preparation: incoming raw materials, acceptance, preparation of formwork system, slow-bonding prestressed tendons 7, non-prestressed steel bars, prestressed anchors, etc. required for construction;

[0057] S2: Bottom form laying: Lay the bottom form of the prestressed reinforced concrete beam, preset the back arch of the bottom form according to the back arch value provided by the design, and the back arch value needs to be adjusted appropriately according to the actual construction and the tension of the beam;

[0058] S3: Installation of non-prestressed steel skeleton: Before binding the steel bars, clean the bottom mold and apply a layer of release agent. The steel bars are installed and bound in a certain order in strict accordance with the construction drawings, and care should be taken to place the pads reasonably to ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com