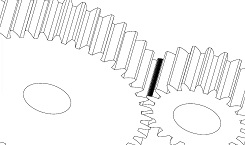

Gear with bionic non-smooth surface and machining method thereof

A non-smooth surface and surface processing technology, applied to components with teeth, metal processing equipment, gear lubrication/cooling, etc., can solve the problem of difficult control of material properties and structural dimensions, affect the consistency of gear surface quality, and prolong the manufacturing cycle to reduce the probability of sliding plow damage, avoid damage, and improve stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

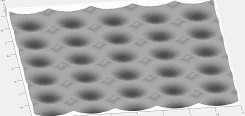

[0018] High-speed milling with ball-end milling cutter, the inclination angle between the milling cutter and the gear working surface is in the range of 20°~30°, the cutting amount on the back of the milling cutter is between 0.1~0.25mm, and the relationship between the machining line spacing and the feed amount per tooth of the milling cutter It is 2:1, the feed rate of each tooth of the milling cutter is between 0.1~0.5mm / z, and the feed direction of the milling cutter is parallel to the direction of the gear pair transmission. By adjusting the milling parameters, the working surface of the gear can be processed. Regular quadrilateral pit-like surface morphology, and the quadrilateral pits are evenly distributed.

[0019] Using experiments and ANSYS software to load and analyze the stress of the new gear, the results show that when the working surface of the gear is evenly distributed with a quadrilateral pit with a depth of 0.05mm, a length of 0.706mm, and a width of 0.351mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com