Copper alloy compositions having enhanced thermal conductivity and wear resistance

A technology of copper alloy and composition, which is applied in transportation and packaging, metal processing equipment, metal material coating technology, etc., and can solve problems such as reducing thermal conductivity

Inactive Publication Date: 2021-05-25

MATERION

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Contains some additives (e.g. lubricants) that tend to reduce thermal conductivity

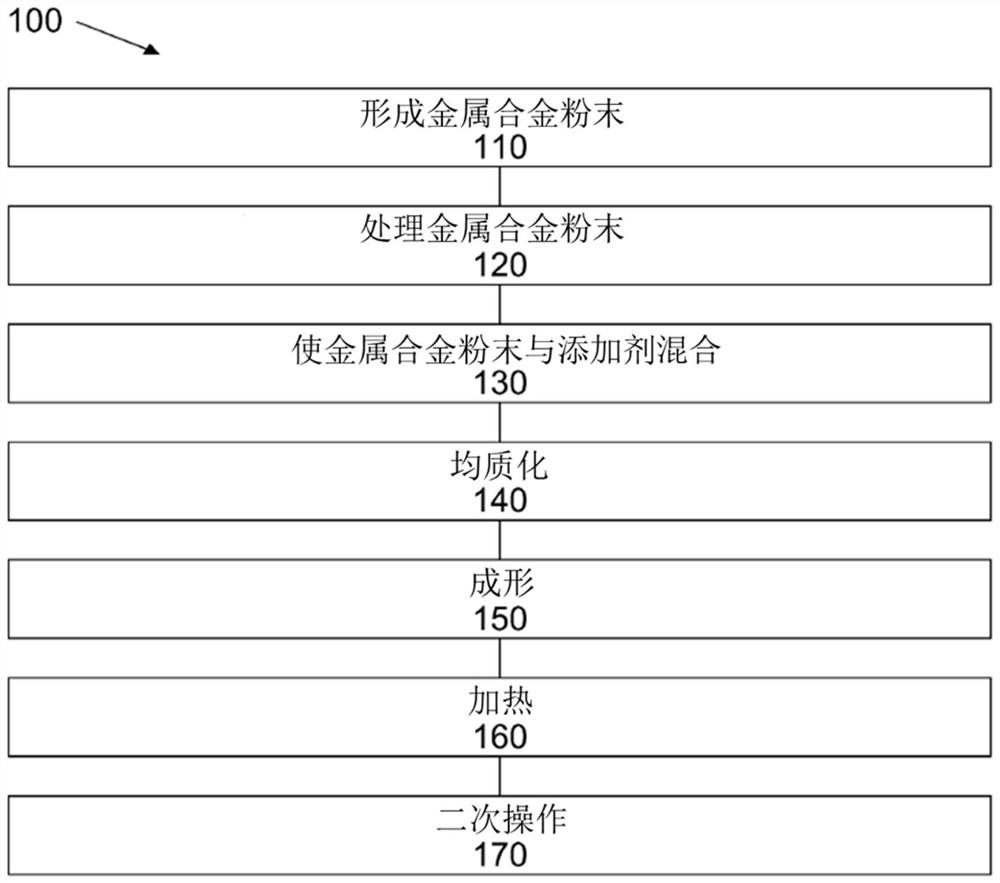

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0105] Figure 6A is a cross-sectional view of the surface of a mechanically roughed aluminum substrate. The mechanically roughened surface was thermally sprayed with a copper-containing alloy, resulting in a copper-containing alloy layer approximately 150 microns thick. Figure 6B A rough machined aluminum substrate is shown after thermal spraying of a Cu-containing alloy.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Login to View More

Abstract

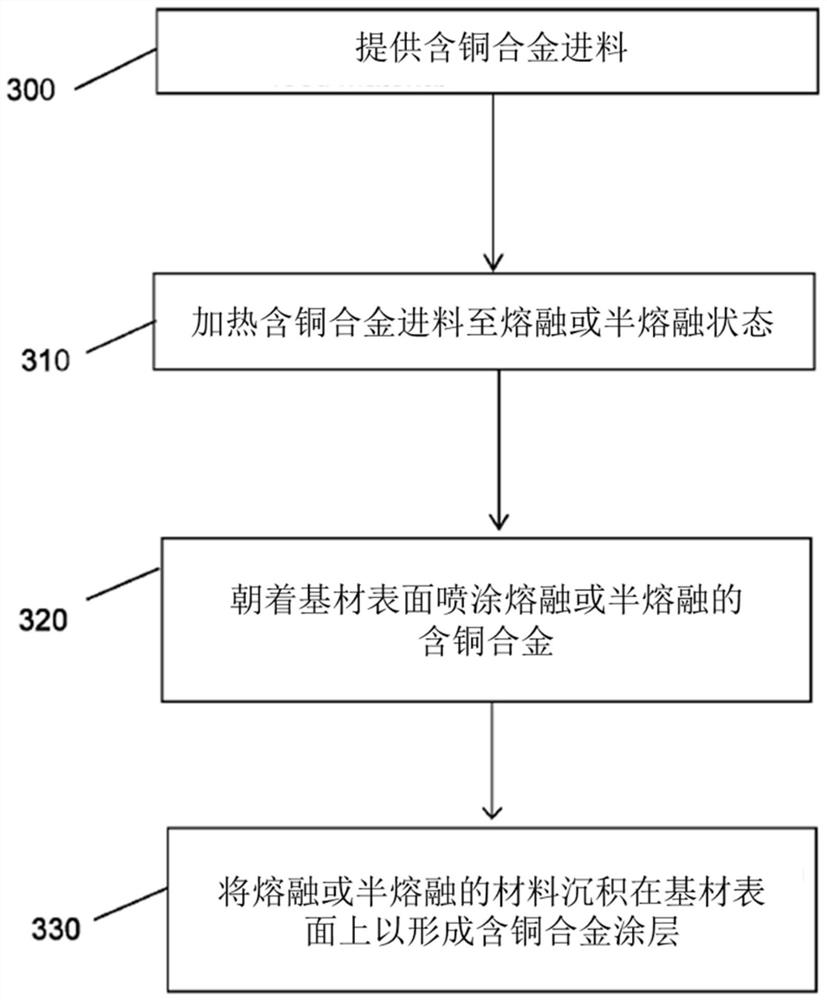

The present disclosure relates to powders and wires made from a copper-containing alloy. The copper-containing alloy is a copper-nickel-tin alloy or a copper-nickel-silicon-chromium alloy. Articles formed from the metal powder exhibit high thermal conductivity, high wear resistance, and thermal stability. The powders and wire also be used as a feed material for thermal spraying and copper-containing coatings are disclosed. The copper-containing alloy material promotes increased life of engine components and fuel efficiency when used as a cylindrical liner in an internal combustion engine.

Description

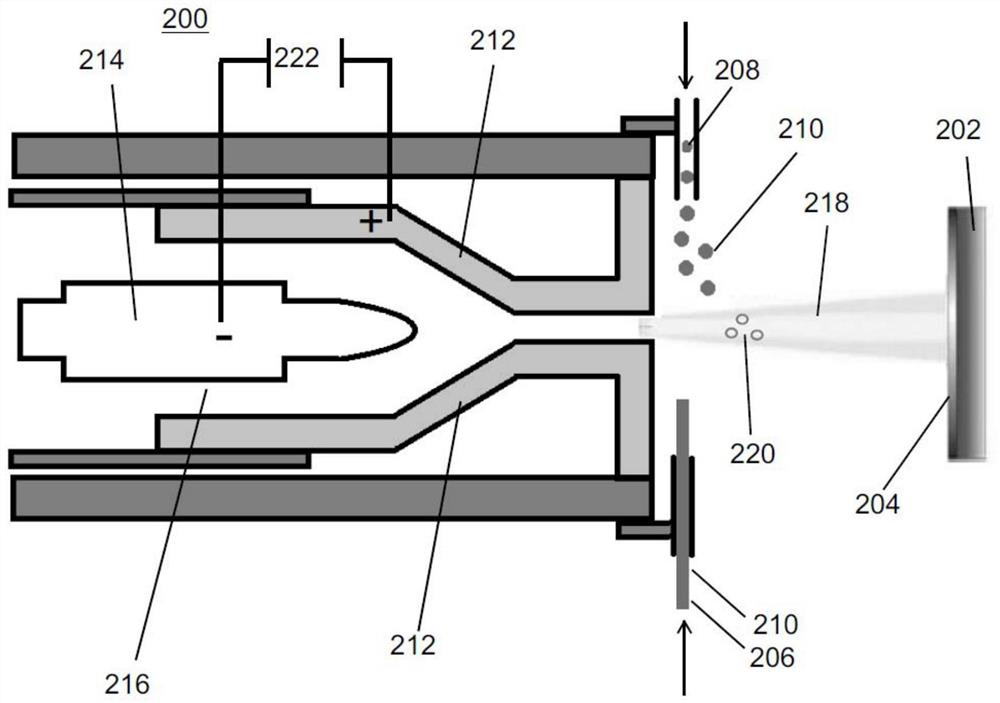

[0001] Cross References to Related Applications [0002] This application claims priority to U.S. Provisional Patent Application No. 62 / 648,567, filed March 27, 2018, the entire contents of which are incorporated herein by reference. Background technique [0003] The present disclosure relates to copper alloy compositions in powder or wire form, processes for making and using such compositions in powder form, articles formed therefrom, and their use as feedstock for thermal spray coatings and plasma spray coatings use. The alloy is a copper-containing alloy exhibiting high thermal conductivity and high wear resistance. Thermal spray coatings exhibit high thermal conductivity, good wear resistance and thermal stability. The coating has particular application in combination with linings and coatings for internal combustion engines. [0004] The demands placed on components for combustion engines are high. It is especially important that these components simultaneously exhibi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C9/06B22F1/00C22C1/04C22F1/08C23C4/08C23C4/123C23C4/131C23C4/134B22F1/05B22F1/10

CPCF02F5/00F16J10/04B22F2998/10C22C1/0425C22C9/06C22F1/08C23C4/08C23C4/123C23C4/131C23C4/134F02F1/00F01L3/02F01L2301/00F01L2303/00B22F1/10B22F1/05B22F3/20B22F3/18B22F3/225B22F3/15B22F3/14B22F1/07B22F5/008B22F5/02B22F2301/10C23C4/06F16J9/26B22F3/115

Inventor 斯蒂芬·麦克弗里茨·C·格雷辛卡罗勒·L·特雷布斯大卫·J·克鲁斯

Owner MATERION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com